Tired of bulky packaging that eats shelf space and inflates shipping costs? Stand-up pouches might be the efficient solution you’ve overlooked.

Stand-up pouches can be used for a wide range of products including food, beverages, cosmetics, and even pharmaceuticals. They offer excellent shelf visibility, lightweight transport, and reliable product protection.

When I first mailed 1 kg of trail-mix in a stand-up pouch to a buyer in Chicago, he weighed it next to his habitual PET jar. The scale read 45 % lighter. He emailed: “We just saved half the freight before even negotiating rates.”

Before diving deeper, let’s explore some common questions businesses often have about stand-up pouches.

What size stand-up pouch do I need?

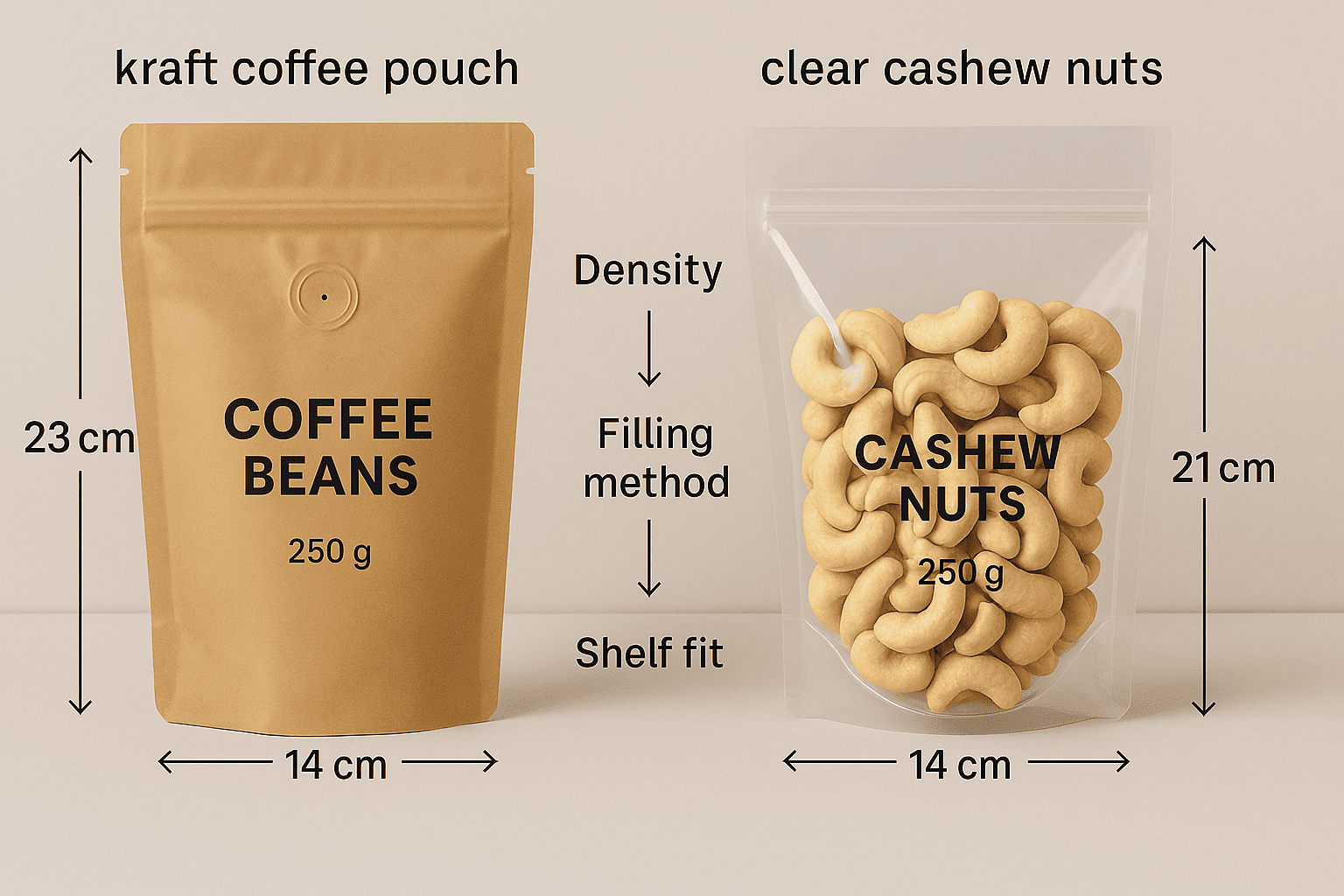

Confused about choosing the right pouch size1? Selecting a pouch without considering product specifics can lead to unstable packaging and wasted space.

The pouch size you need depends on your product’s density, filling method, and shelf or shipping requirements. Consider volume, filling space, and practical shelf display dimensions to optimize pouch selection.

Choosing the right size pouch involves a straightforward three-step checklist. First, evaluate your product’s density. A pouch for 250g of coffee beans, which are lighter and bulkier, requires a wider base compared to 250g of denser cashews. Next, consider your filling process. Powdered products need a clean sealing area, typically around 5mm, to avoid contamination and sealing issues. Finally, think about your product’s placement. E-commerce shipments require stronger bottoms (at least 30mm wide) and rounded corners for drop protection, while retail products must align with shelf heights to maintain zipper visibility. Remember this simple formula: Density × Filling Method × Shelf Requirements = Ideal Pouch Size.

Factory note — Yesterday the line switched from Vietnamese cashews to Brazilian coffee beans. We widened the bottom gusset by 5 mm; the filled pouch stood so firmly it looked glued to the conveyor.

How are stand up pouches sealed?

Ever experienced leaks or weak seals damaging your product’s integrity? Poor sealing techniques2 can seriously impact your product’s quality and customer satisfaction.

Stand-up pouches are typically heat-sealed at temperatures ranging between 90-160°C, applying pressures of 0.4-0.6 MPa for around 0.5-1 second. Proper sealing ensures optimal strength, leak prevention, and contamination resistance.

Sealing stand-up pouches effectively is similar to sealing dumplings—clean edges, firm pressure, and proper temperature control are essential. Increasing sealing temperature by 10°C can boost seal strength by around 15%, but stability is key; temperature variations should be less than 10°C. Typical machine pressure settings between 0.4-0.6 MPa ensure tight seals, and products containing chunks or bones might need slightly increased pressure. Short sealing durations (0.5-1 second) prevent wrinkled appearances. Implementing a small air knife to clear dust particles before sealing significantly reduces rework rates, enhancing production efficiency and package reliability.

Factory note — We added a tiny air-knife right before the sealing jaws last week. Seal-leak rejects dropped from 5 % to 0.6 % overnight.

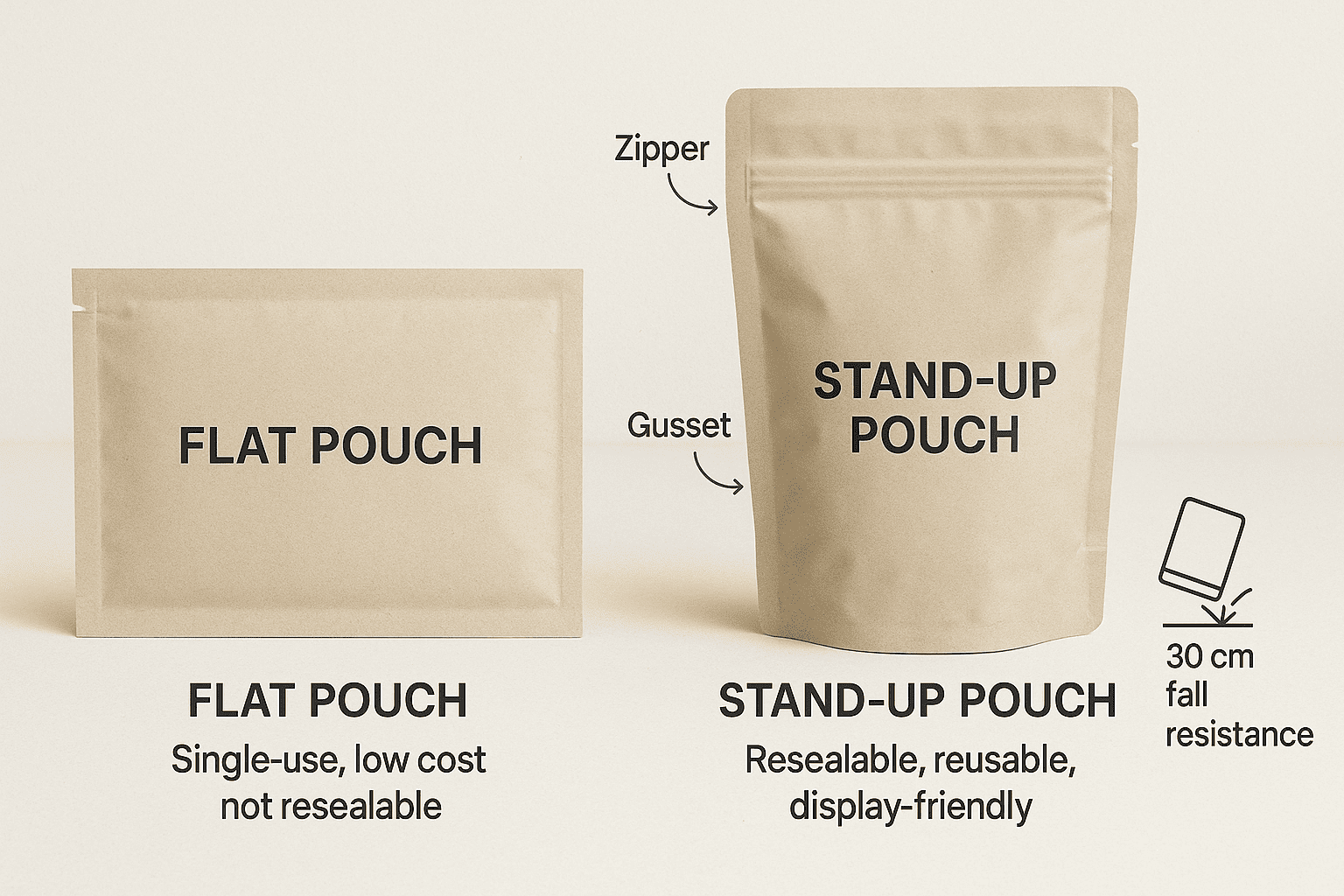

What is the difference between a flat pouch and a stand-up pouch?

Wondering if choosing between flat pouches and stand-up pouches really matters? Picking the wrong one can affect your product’s display effectiveness and customer usability.

The primary difference is that stand-up pouches have a stable bottom gusset, allowing upright display and multiple openings. Flat pouches are simpler, thinner, and designed mainly for single-use items and one-time openings.

Flat pouches are like envelopes—simple, flat, and cost-effective—but they’re not designed for repeated use or prominent display. They’re ideal for single-use products like seasoning packets or promotional samples. Stand-up pouches, on the other hand, feature a gusseted bottom providing structural support, allowing products to stand independently. They withstand greater impact from falls, typically about 30 centimeters higher than flat pouches made from identical materials. These pouches also support resealable closures, perfect for products consumed over multiple sessions. If visibility, durability, and reusability matter to your brand, stand-up pouches are the clear choice.

Factory note — A drop-test rig showed our 250 g curry-sauce pouch survived a 1.1 m fall, while the equivalent flat pouch burst at 0.8 m.

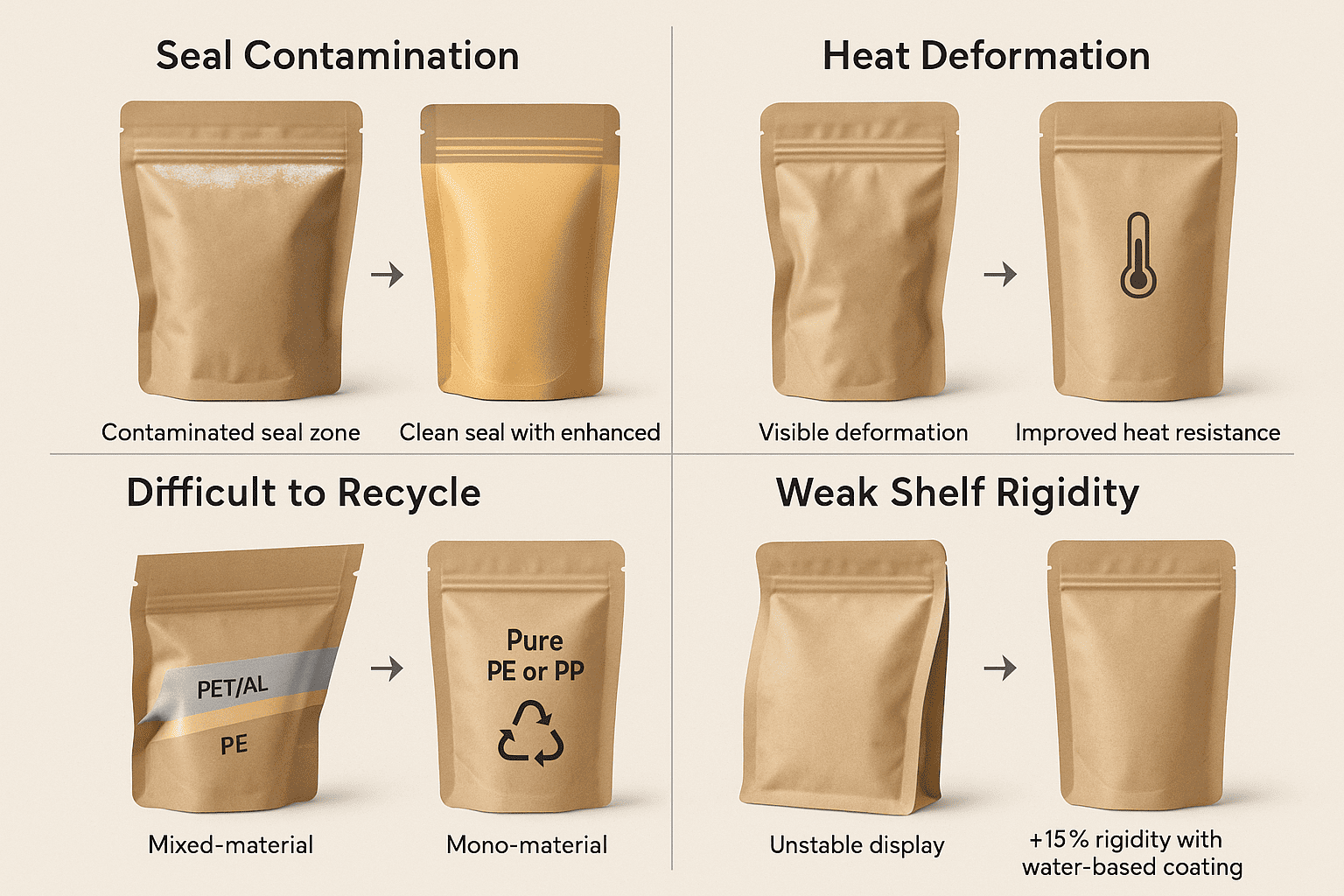

What are the disadvantages of pouch packaging?

Considering stand-up pouches3 but concerned about potential downsides? Recognizing limitations helps you proactively manage packaging challenges.

Main disadvantages include sealing issues due to contamination, limited temperature tolerance during sterilization, recycling difficulties, and lower shelf rigidity. Each problem, however, has a targeted solution through material or design enhancements.

Stand-up pouches, although beneficial, do have limitations. First, contamination at sealing points by oil or dust can cause leaks. This can be solved by designing a clean sealing area and applying slightly longer, high-pressure heat sealing. Second, they can deform under high-temperature sterilization, resulting in wrinkles or delamination. Switching to temperature-resistant adhesives or solvent-free lamination improves durability. Recycling is challenging because traditional multi-layer materials are difficult to separate, potentially incurring additional fees in markets like Europe. Transitioning to single-material structures (such as pure PE or PP with transparent barrier coatings) solves recyclability issues. Lastly, shelf rigidity can be weak, causing packaging to slump or crease. Applying a water-based external coating can improve rigidity by up to 15% without significantly increasing weight, ensuring stability and visual appeal.

Factory note — Switching the outer layer to a water-based coated PE film raised panel stiffness by 15 % with virtually zero weight gain.

FAQ

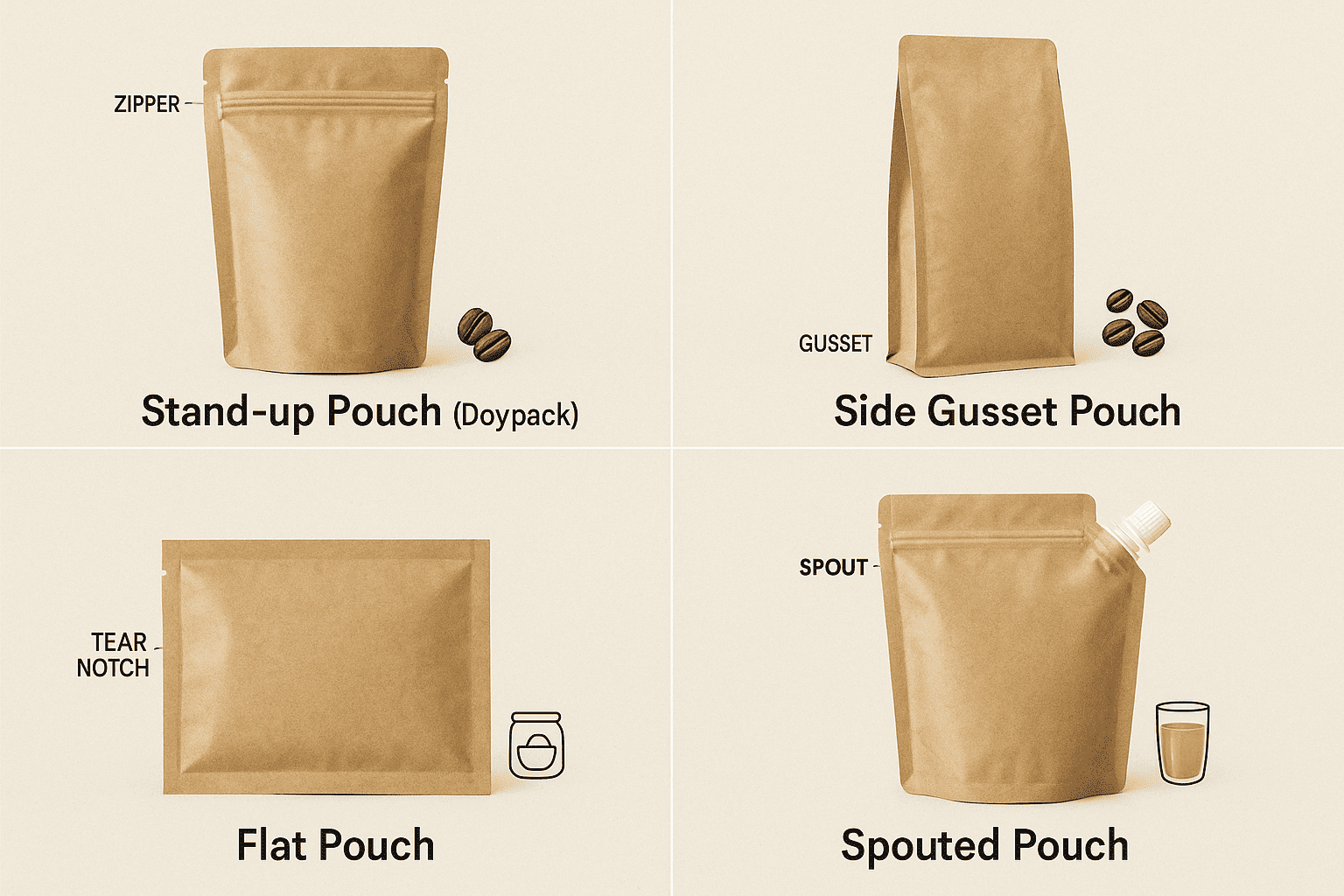

How many types of pouches are there?

Feeling overwhelmed by the variety of pouch options? Clearly understanding pouch types helps simplify your packaging selection process.

There are several common types: Stand-up (Doypack), side gusset, flat, and spouted pouches. Additional variations include features like zippers, valves, and hang holes, tailored to specific needs.

| Type of Pouch | Features | Typical Uses |

|---|---|---|

| Stand-up | Gusset bottom, resealable zippers | Snacks, beverages, pet food, cosmetics |

| Side Gusset | Side folds, great for bulk products | Coffee, tea, larger food packaging |

| Flat | Simple, thin, single-use design | Condiments, single-dose products |

| Spouted | Pourable spout, easy dispensing | Baby food, liquid detergents, beverages |

Each pouch type has unique advantages. For example, stand-up pouches enhance shelf presence, while flat pouches save space for single-use items. Understanding your product’s use, filling, and marketing needs simplifies selecting the right pouch type, ensuring packaging effectiveness.

Quick numbers to remember

- Shipping weight versus a glass jar of equal volume: -63 %

- Extra safe drop height over a flat pouch: +30 cm

- EU recycling surcharge on multi-layer laminates: €0.17 per kg

Conclusion

Stand-up pouches offer flexible, sustainable, and versatile packaging solutions. Clearly understanding their advantages and limitations helps brands optimize product presentation, durability, and customer satisfaction effectively.

Still packing your new launch in “steel boots,” or will you let it sprint in a lightweight pouch? Send me the formula specs today, and I’ll mock up a sample that aces the drop test by tomorrow.

-

Learn how to select the ideal pouch size based on product density and filling methods to optimize packaging. ↩

-

Discover effective sealing methods to ensure product integrity and prevent leaks in stand-up pouches. ↩

-

Explore the advantages of stand-up pouches, including their efficiency, visibility, and protection for various products. ↩