The coffee industry spends millions on "sustainable" packaging that ends up in landfills anyway. Your customers demand eco-friendly solutions, but most options fail to deliver real environmental benefits.

I’ve found that truly sustainable coffee packaging isn’t about chasing every biodegradable trend. The best eco-friendly options are recyclable mono-material structures1 with high-barrier coatings2 and post-consumer recycled materials3 with EVOH barriers. These solutions maintain 18-month shelf life while fitting into existing recycling systems. Smart brands are also using larger format bags with resealable features to reduce packaging per pound by 40%.

Most "compostable" coffee bags need industrial composting facilities that don’t exist in 90% of markets. I’ve watched brands fail because they prioritized green marketing over actual performance. Your eco-friendly bag means nothing if coffee goes stale in three weeks. Let me show you options that actually work.

What Makes Coffee Packaging Truly Sustainable?

Coffee packaging sustainability goes beyond simple labels like "biodegradable" or "recyclable." Real sustainability requires balancing multiple factors that many brands overlook.

True sustainability in coffee packaging means considering five key metrics: material circularity, carbon footprint, reliance on virgin fossil fuels, end-of-life design, and actual recycling infrastructure availability. The most effective sustainable coffee bags use mono-material structures or post-consumer recycled content while maintaining essential barrier properties. These materials must protect coffee quality for at least 12-18 months while being genuinely recyclable in existing waste streams.

I measure sustainability through Material Circularity Indicator (MCI) scores4. This metric shows how well materials perform in real circular economy systems. A score of 0 means completely linear (virgin materials to landfill). A score of 100 means perfectly circular (recycled materials that can be recycled forever).

Understanding Real vs. Greenwashing

Many coffee brands fall into greenwashing traps5. They choose materials that sound eco-friendly but create more problems. Here’s what I see happening:

Biodegradable films often need specific conditions to break down. Without industrial composting, they act like regular plastic. Plant-based plastics still require virgin materials and energy-intensive processing. Multi-layer laminates with paper exteriors look natural but can’t be recycled due to plastic linings.

The solution is choosing materials based on data, not marketing claims. Last year, I convinced a client to choose recyclable PE over "biodegradable" PLA by showing local composting data. This approach helps brands avoid costly mistakes while achieving real environmental benefits.

Which Recyclable Materials Work Best for Coffee Bags?

Recyclable materials offer the most practical path to sustainable coffee packaging6. But not all recyclable options deliver equal results.

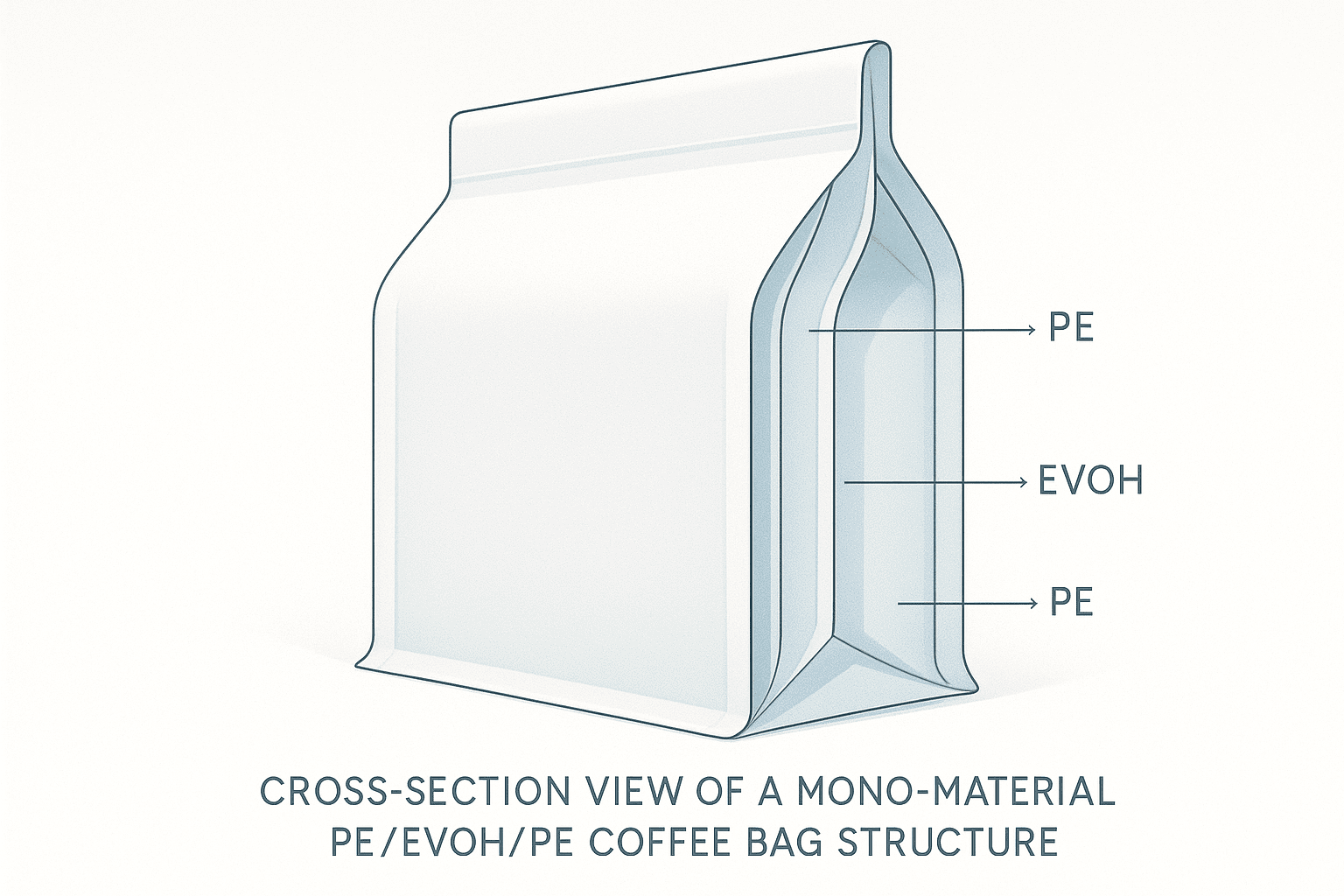

The best recyclable coffee bag materials are mono-material polyethylene (PE) structures with EVOH barriers and post-consumer recycled content. These materials achieve recycling rates up to 60% in developed markets while maintaining 18-month shelf life. I recommend PE/EVOH/PE structures for stand-up pouches and flat-bottom bags, as they balance sustainability with essential barrier properties at competitive costs.

Post-consumer recycled (PCR) materials reduce virgin plastic use by up to 80%. I work with converters who run both flexo and digital printing on these materials. This allows prototyping without huge minimum orders that kill innovation.

Mono-Material Structure Benefits

Mono-material packaging uses one type of plastic throughout the structure. This design makes recycling much easier. Traditional coffee bags use multiple materials laminated together. Recycling facilities can’t separate these layers.

My mono-material recommendations include:

- PE/PE structures for lighter roasts with faster turnover

- PE/EVOH/PE for premium coffees needing extended shelf life

- PP/PP structures for markets with PP recycling infrastructure

These materials work in existing mechanical recycling systems. No special facilities needed. Brands using these materials report recycling rates 3-4 times higher than multi-layer alternatives.

How Do Compostable Coffee Bags Really Perform?

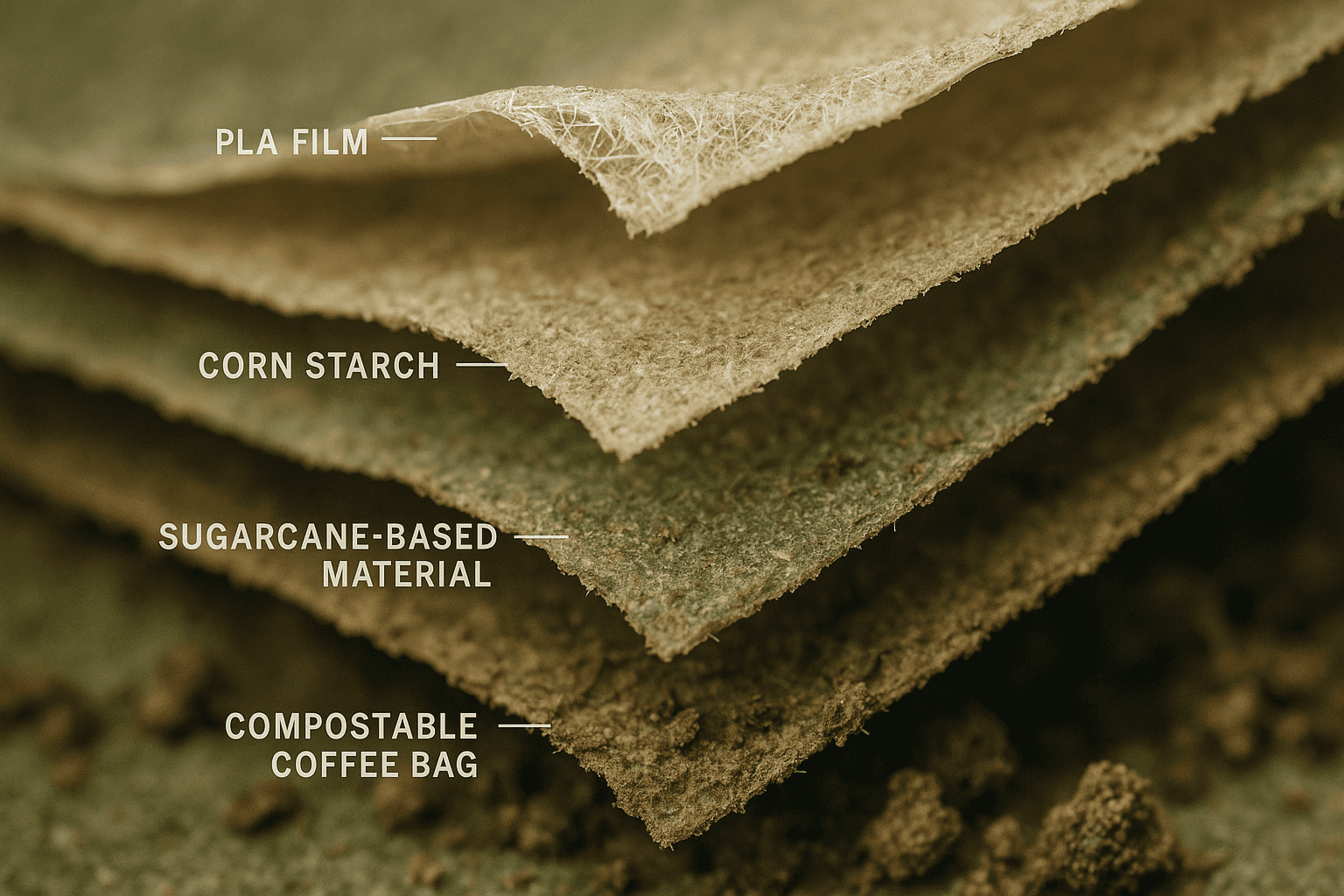

Compostable packaging promises to solve waste problems, but reality is more complex. Most compostable coffee bags7 face serious practical challenges.

Compostable coffee bags made from PLA or other bioplastics can decompose in 90 days under industrial composting conditions. However, less than 10% of consumers have access to industrial composting facilities. Home compostable options exist but typically offer only 6-9 month shelf life due to lower barrier properties. I recommend compostable bags only for local markets with established composting infrastructure and faster product turnover.

The main compostable materials I work with include:

PLA (Polylactic Acid) Based Films

PLA comes from renewable sources like corn starch or sugarcane. It provides moderate barrier properties and clear appearance. But PLA needs temperatures above 140°F to compost properly. Home compost bins rarely reach these temperatures.

Cellulose and Paper-Based Compostables

These materials use renewable wood pulp with water-based barrier coatings. They offer better home compostability but lower moisture barriers. I’ve seen these work well for:

- Local roasters with quick turnover

- Subscription services with frequent deliveries

- Markets with strong composting programs

The challenge is balancing compostability with performance. Brands must decide between longer shelf life or easier disposal. There’s no perfect solution yet.

What About Paper Coffee Bags with Eco-Friendly Linings?

Paper bags appeal to consumers seeking plastic-free options. But pure paper can’t protect coffee adequately. Modern solutions combine paper with sustainable barrier layers.

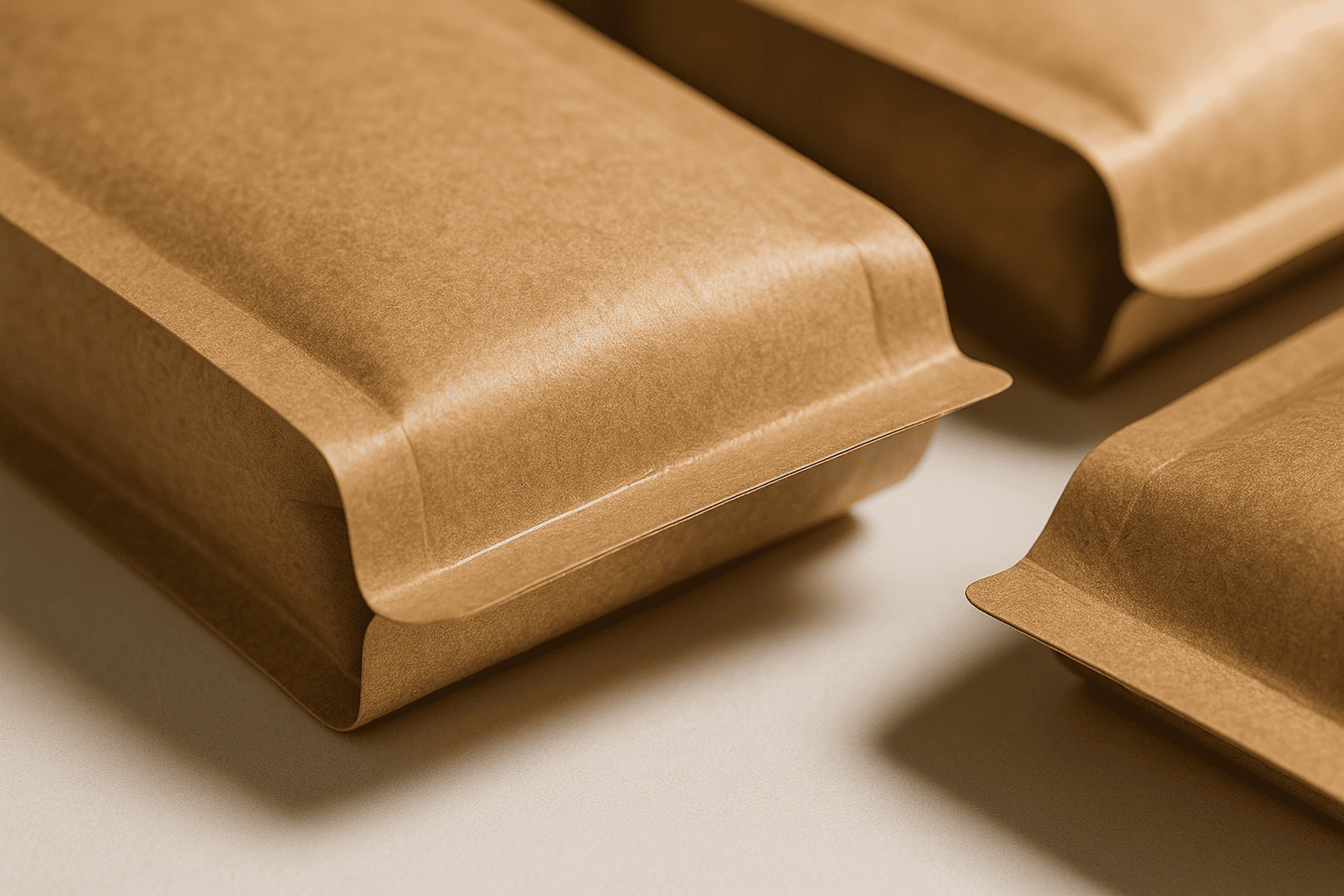

Paper coffee bags with eco-friendly linings8 use FSC-certified kraft paper combined with thin barrier films. The best options feature water-based coatings or ultra-thin recyclable PE linings under 5% of total weight. These bags achieve 12-month shelf life while remaining recyclable in paper streams. I suggest flat-bottom paper bags9 with PE linings for retail environments where shelf appeal matters most.

Recently, when working with an organic coffee producer, they were concerned that paper packaging wouldn’t perform as well as plastic bags on retail shelves. We designed a special flat-bottom paper bag structure with a 4.2% PE lining that guaranteed 12-month freshness while delivering excellent shelf presentation. Three months later, their retail partners reported that this packaging had 40% better visual appeal than their previous plastic packaging, proving the tremendous potential of paper-based solutions in retail environments. This experience taught me that paper-based solutions work best when designed for specific recycling streams.

Coating Technologies That Maintain Recyclability

New coating technologies allow paper bags to maintain recyclability while providing barriers. These include:

Water-based barriers that repel moisture without plastic films. They break down in standard paper recycling. Bio-polymer coatings from renewable sources that dissolve during recycling. Ultra-thin PE coatings below 5% threshold for paper recycling acceptance.

I work with suppliers who specialize in these coatings. Digital printing works perfectly on these materials. This allows custom designs without massive minimum orders. Brands can test different designs before committing to large runs.

How Can Bag Design Reduce Environmental Impact?

Smart design reduces environmental impact more than material choice alone. Simple changes can cut packaging waste by 30-50%.

Optimized bag design reduces environmental impact through larger formats, concentrated products, and efficient shapes. Moving from 12oz to 2lb bags cuts material use per pound by 40%. Adding resealable features extends product life and reduces food waste. I recommend flat-bottom bags with tear-away tops and press-to-close zippers for maximum material efficiency and user convenience.

Design strategies that make real differences include:

Size Optimization

Larger bags use less material per pound of coffee. A 5lb bag uses 60% less packaging than five 1lb bags. But consumers still want convenience. The solution? Resealable features that keep coffee fresh after opening.

Lightweighting Techniques

Modern materials provide same barriers with less weight. I’ve helped brands reduce material weight by 20-30% without sacrificing protection. This cuts both material costs and shipping emissions.

Supply Chain Efficiency

Efficient bag shapes pack better for shipping. Flat-bottom bags stack more efficiently than stand-up pouches. Side-gusset bags ship flat and expand when filled. These details add up to significant carbon reductions across the supply chain.

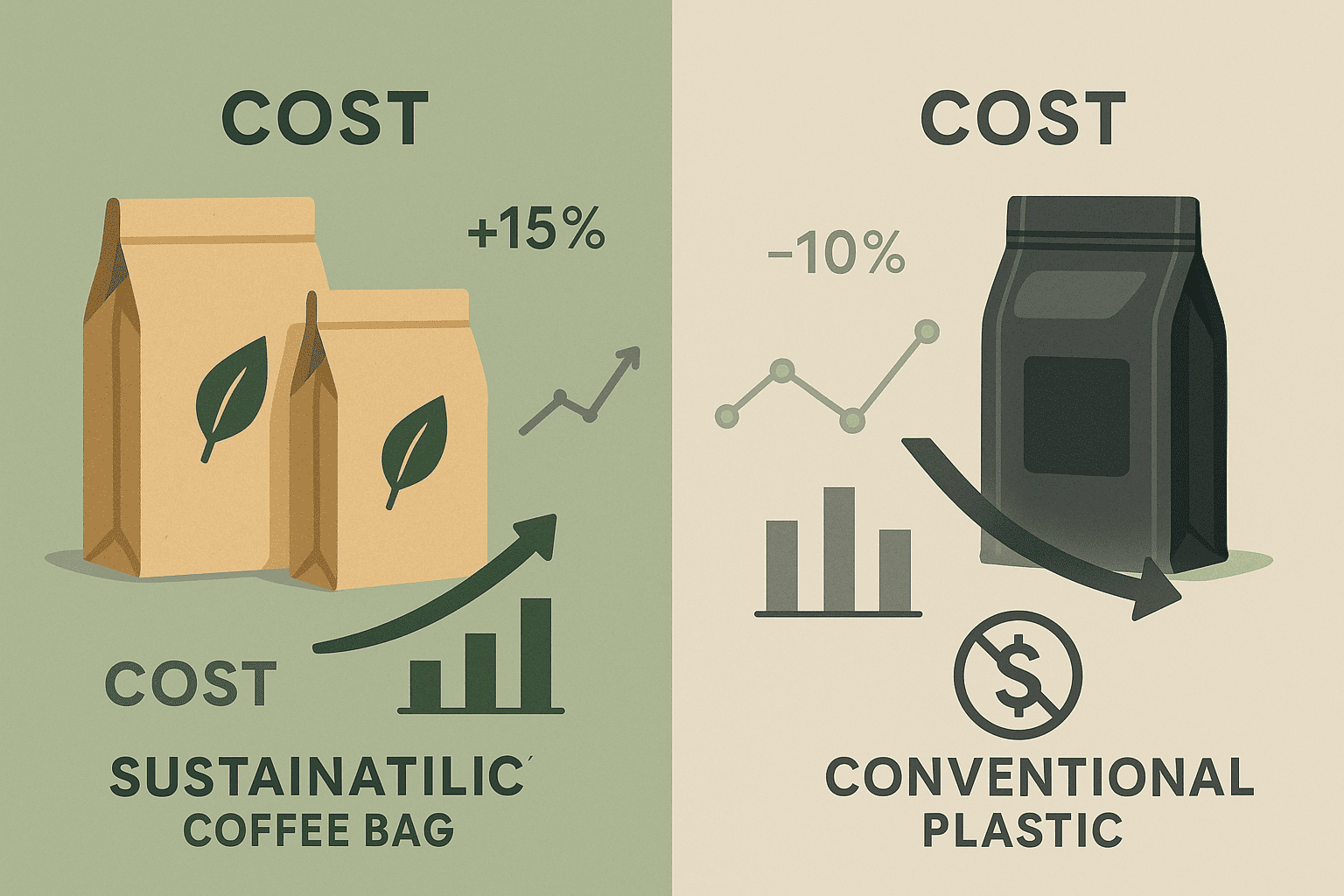

What’s the Real Cost of Sustainable Coffee Packaging?

Sustainable packaging costs more upfront but delivers long-term value. Understanding true costs helps make better decisions.

Sustainable coffee packaging typically costs 10-20% more than conventional options initially. However, total system costs often favor sustainable solutions through reduced disposal fees, improved brand value, and customer loyalty. Post-consumer recycled materials cost 15% more than virgin plastics but can increase customer lifetime value by 25%. I advise calculating total cost including waste management, brand perception, and regulatory compliance.

Hidden costs of conventional packaging include:

- Rising landfill fees and taxes

- Lost customers seeking sustainable brands

- Future regulatory compliance costs10

- Brand damage from environmental criticism

A client initially hesitated over 20% higher costs until competitor gained market share with eco-friendly positioning and premium pricing. This showed me that sustainable packaging is an investment, not just an expense.

ROI Calculation Methods

I help clients calculate real ROI for sustainable packaging. Key metrics include:

Customer acquisition cost reduction from sustainability messaging. Increased purchase frequency from eco-conscious consumers. Premium pricing power for sustainable products. Reduced regulatory risk as laws tighten globally.

Most brands see positive ROI within 18-24 months. Early adopters gain competitive advantages that grow over time. Waiting costs more than acting now.

Common Questions About Eco-Friendly Coffee Packaging

1. Can biodegradable bags really preserve coffee freshness?

Current biodegradable materials provide 6-12 month shelf life compared to 18-24 months for conventional packaging. They work best for local markets with quick turnover. For longer shelf life, recyclable mono-materials offer better performance.

2. How do I choose between recyclable and compostable options?

Check your local waste infrastructure first. If recycling rates exceed 40%, choose recyclable mono-materials. If industrial composting exists, consider compostable options. Without either, focus on reducing material use overall.

3. What certifications should I look for?

Look for How2Recycle labels for recyclability, BPI or TUV certification for compostability, and FSC certification for paper materials. These certifications verify environmental claims with third-party testing.

4. Will sustainable packaging hurt my brand’s premium image?

Quality sustainable packaging enhances premium positioning. Modern eco-friendly materials offer excellent printing quality and tactile appeal. Many premium brands report increased sales after switching to sustainable packaging.

Conclusion

Real eco-friendly coffee packaging goes beyond marketing claims. Focus on recyclable mono-materials and post-consumer recycled content that work in existing infrastructure. Design bags for efficiency, not just appearance. The future belongs to brands investing in genuine sustainability, not chasing every biodegradable trend.

-

Learn about recyclable mono-material structures and their benefits for sustainable packaging solutions. ↩

-

Find out how high-barrier coatings enhance the shelf life of products while being eco-friendly. ↩

-

Discover how post-consumer recycled materials contribute to reducing waste and promoting sustainability. ↩

-

Understand the importance of MCI scores in evaluating the sustainability of packaging materials. ↩

-

Learn to identify greenwashing traps to make informed choices about sustainable packaging. ↩

-

Explore this resource to understand effective strategies for creating truly sustainable coffee packaging. ↩

-

Learn about the performance of compostable coffee bags and their suitability for various markets. ↩

-

Discover the innovations in eco-friendly linings that enhance the sustainability of paper bags. ↩

-

Discover why flat-bottom paper bags are an effective choice for coffee packaging. ↩

-

Learn about the importance of regulatory compliance in sustainable packaging practices. ↩