Side Gusset Pouch Manufacturer & Custom Printing

Tell us what you pack. We’ll tailor materials, printing, and add-ons so your pouch meets shelf-life, branding, and launch speed.

- Get started with low MOQ and fast production

- Choose recyclable #4/#5 or compostable options

- Get engineering advice before you order

What Is a Side Gusset Pouch?

Two side folds expand to add volume and help the pouch stand once filled—so you get more product in a tidy footprint. Different from flat bottom and quad-seal formats.

- Packs more without a bigger shelf footprint.

- Stands upright after filling for clean display.

- Four strong brand faces: front, back, and both sides.

- Works with add-ons you may need: degassing valve, zippers, tear notches, hang or handle holes.

Side Gusset vs. Flat Bottom vs. Quad Seal

Choose the right pouch structure for volume efficiency, shelf presence, and production compatibility.

A quick, decision-ready comparison of side gusset pouches, flat bottom pouches, and quad seal pouches—so your team can balance branding, capacity, and line speed with confidence.

- Side gusset: highest fill volume per footprint, classic coffee look

- Flat bottom: best standability and billboard panels, premium presence

- Quad seal: reinforced corners and better cube, strong for heavier packs

| Attribute | Side Gusset Pouch | Flat Bottom Pouch | Quad Seal Pouch |

|---|---|---|---|

| Volume Efficiency | High—deep side folds boost capacity | Medium—boxy, but less internal depth | Medium/High—good cube with corner seals |

| Standability & Shelf Blocking | Good—classic coffee stance | Best—rigid base and 5 faces | Good—reinforced vertical edges |

| Max Weight Range | Up to 5 lb (spec-dependent) | Up to 5–10 lb (spec-dependent) | Up to 10 lb (spec-dependent) |

| Valve / Closure Options | Valve, tin tie, zipper limited by spec | Valve, zipper, tin tie | Valve, zipper |

| Machine Compatibility | Premade pouch lines, manual fill | Premade, some FFS with right tooling | Premade, FFS for high volume SKUs |

| Unit Economics | Most cost-effective at scale | Premium look, higher unit cost | Balanced—strong cube vs. cost |

| Best For | Coffee beans/powders, dry goods, pet food up to 5 lb | Premium retail SKUs, gift lines, storytelling panels | Heavier packs, larger formats, shipping efficiency |

Side Gusseted Pouch Use Cases & Best Practices

Pick a side gusset pouch spec that fits your product—and follow proven setup tips for barrier, closures, and labeling.

Side Gusset Coffee Bags

- Pack within 12–24 hours after roast for whole beans, add a one-way degassing valve

- Popular fills: 8 oz / 12 oz / 1 lb / 2 lb, tall profile for strong shelf blocking

- Suggested seal width: 8–12 mm, consider nitrogen flush for extended freshness

- Graphics: four-panel storytelling, keep barcode quiet zone ≥ 0.25 in

- Closures: heat seal + optional tin tie, zipper availability depends on spec

Spec highlight

- ✅ Structure: PET/VMPET/PE or PET/AL/PE

- ✅ Typical sizes: 12 oz (340 g), 1 lb (454 g)

- ✅ Valve placement: front or back panel, above center

Side Gusset Pet Food Bag

- Manage abrasion/puncture from kibble, confirm drop tests by target weight

- Side gusset works well for 2–5 lb formats, consider quad seal above that

- Suggested seal width: 10–12 mm, reinforce bottom seal for heavier fills

- Closures: heat seal, optional zipper or tin tie by configuration

- Labeling: large side claims, feeding guide on the back panel

Spec highlight

- ✅ Structure: PET/VMPET/PE (high barrier)

- ✅ Typical sizes: 2 lb / 5 lb

- ✅ Window: optional narrow strip to show kibble size

Side Gusset Dry Goods Bag

- Control moisture, consider desiccants for hygroscopic products

- Clear product cues: optional view window, matte or soft-touch finishes for premium lines

- Suggested seal width: 8–10 mm, tear notch for easy open

- Labeling: nutrition facts & allergens with high contrast

Spec highlight

- ✅ Structure: MDO-PE/PE (recyclable) or PET/VMPET/PE

- ✅ Typical sizes: 250 g / 500 g / 1 kg

- ✅ Closure: heat seal, tin tie for retail re-close

Materials & Sustainability Options

Choose recyclable or compostable structures for your side gusset pouch—then add finishes that match your brand.

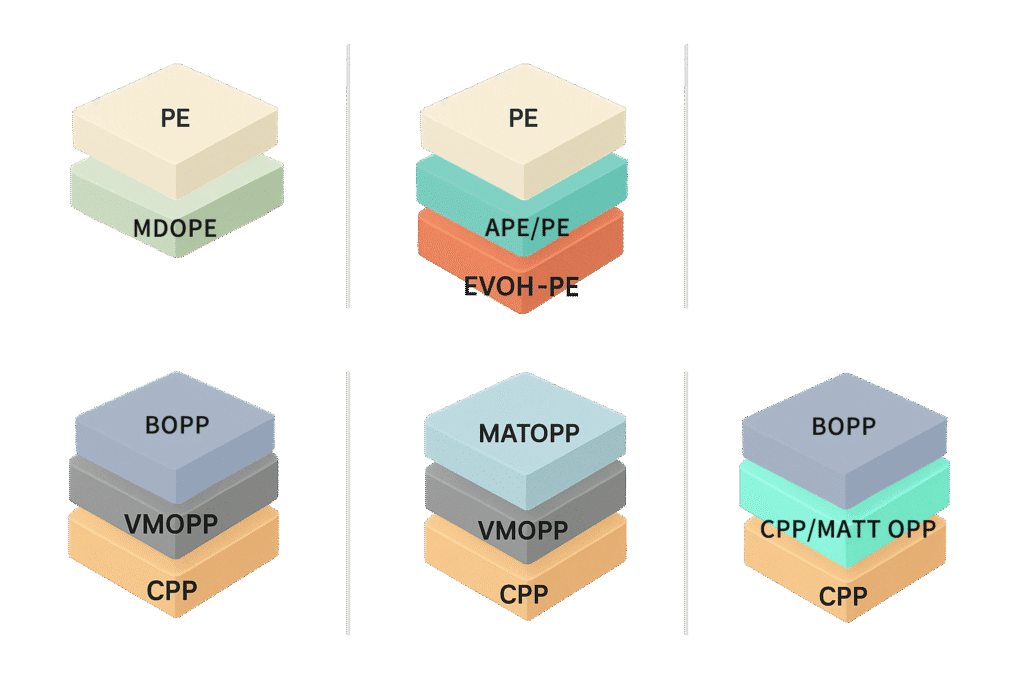

Recyclable (Mono-PE #4 / Mono-PP #5)

- Structures: MDO-PE/PE, PE/EVOH-PE (programs vary by region)

- Closures: heat seal, valve compatible, zipper availability depends on spec

- Finishes: gloss or matte, optional view window

Fit & Limits — Recyclable

- Best for: coffee, dry goods, 250 g–5 lb, retail & distribution

- Not ideal for: very oily/high-moisture fills without extra protection

- Compatibility: valve ✅, tin tie ✅, zipper (spec-dependent)

- Barrier class: medium–high

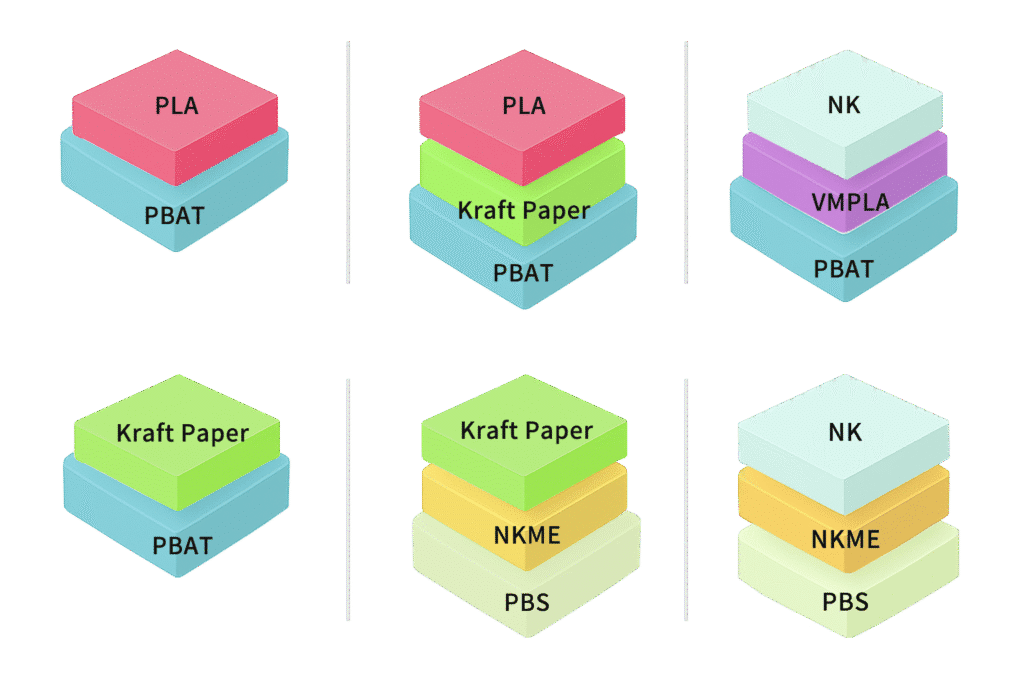

Compostable (Kraft paper / PLA-based)

- Best for shorter shelf-life dry goods, avoid high-moisture or oil-heavy fills

- Closures: heat seal, valve support limited, tin tie optional

- Print: kraft look with strong four-panel branding

Fit & Limits — Compostable

- Best for: 250 g / 500 g / 1 kg short-cycle SKUs

- Not ideal for: long shelf life or humid shipping lanes

- Compatibility: valve ⚠️ limited, tin tie ✅

- Barrier class: moderate

Finishes & Features (Look & Feel)

Apply these add-ons to either recyclable or compostable structures, subject to spec.

Clear / Frosted Window

Product visibility with die-cut or strip windows, adjust opacity and barrier accordingly.

Matte / Soft-Touch Lamination

Premium tactility and glare control, pair with scuff-resistant coatings for retail durability.

Spot Gloss / Matte Varnish

Emphasize logos or claims with selective coatings, compatible with digital or gravure print.

Performance You Can Validate

Publishable barrier, sealing, and strength specs—so operations and QA have facts, not guesses.

Barrier & Shelf Life (at a glance)

| Structure (Example) | Barrier (OTR / WVTR) (cc/m²·day / g/m²·day) | Typical Seal Window (°C) | Valve Support | Notes |

|---|---|---|---|---|

| PET / AL / PE (foil laminate) | ≤ 0.1 / ≤ 0.1 | 140–170 | Yes | Longest shelf-life, excellent oxygen & light barrier |

| PET / VMPET / PE (metallized) | 0.1–1.0 / 0.1–1.0 | 140–170 | Yes | High barrier at great value for coffee & dry goods |

| MDO-PE / PE (recyclable mono-PE) | 1–3 / 1–3 | 150–190 | Yes | Designed for store-drop-off recycling (where available) |

| Kraft / PLA-based (compostable*) | 3–10 / 5–10 | 140–170 | Limited | For shorter shelf-life or specific sustainability goals |

* Values are indicative. Tested per ASTM D3985 (OTR) and ASTM F1249 (WVTR) at 23 °C; final specifications are confirmed on COA by lot.

Sealing & Handling

- Consistent seals across multi-lane or premade pouch lines

- Suggested seal widths: 8–12 mm (final spec by product weight)

- Options: one-way degassing valve, tin tie, tear notch, easy-open

Printing & Branding

Bring your side gusset pouch to life with production-ready artwork, accurate color, and a premium finish.

Printing Methods

- Digital printing— fast turns, low MOQs, versioning & test runs

- Gravure printing — best unit economics at scale, Pantone spot colors, metallics, and effects

- Hybrid approach — gravure for core assets + digital for short seasonal SKUs

Artwork Guidelines

- Dieline: use our official side gusset pouch dielines (AI/PDF)

- Bleed & Safe Area: follow the values indicated on the dieline, keep all critical text and marks inside the safe area, extend backgrounds to the bleed

- Minimum Type & Lines: set body copy and line weights at or above your press legibility threshold (digital/gravure). Avoid hairlines, outline fonts, and proof before mass run

- Color: CMYK and/or Pantone as specified, embed profiles, define white ink as a spot plate if required

- Layers & Overprint: expand effects, outline fonts, and review separations/overprint intentionally

Branding Tips for Side Gusset Pouches

- Use all four panels (front hero, back story, side claims & regulatory info)

- Align art with valve/tin tie locations, consider a narrow window for product cues

- On kraft looks, keep high-contrast inks for legibility

Samples, MOQ & Lead Times

Validate print, hand-feel, and fit fast—then plan your run with clear MOQs and a reliable timeline. We confirm shipping and any prototype fees during quoting.

Samples

Get the right feel before you commit. We ship existing samples quickly so you can check print quality and rough fit.

MOQ

Start small or scale up when ready. Digital: 1,000 pcs · Gravure: 5,000 pcs per design.

Production Time

Hit your launch date with a dependable window—15–22 days in production (transit not included). Rush available—talk to sales.

FAQs about Side Gusset Pouches

What is a side gusset pouch?

A flexible pouch with expandable side folds that increase capacity and help the bag stand once filled.

Side gusset vs. bottom gusset—what’s the difference?

Side gusset adds depth on the sides, bottom gusset adds a base panel for a flatter footprint. Pick by display style and line fit.

Side gusset vs. stand-up pouches—how do I choose?

Side gusset excels for bigger fills and efficient case-pack, stand-up pouches prioritize on-shelf flat stability. Choose by format and shelf look.

Are side gusset pouches good for coffee?

Yes—commonly used for whole-bean and ground coffee. Many teams add a degassing valve to manage CO₂.

Do side gusset pouches stand up on their own?

Once filled, yes—they form a stable profile due to the side folds. (Empty, they don’t have a flat base like flat-bottom.)

How do you measure a side gusset bag?

Use W × D × L (Width × Depth/gusset × Length/Height). This is the standard convention for side-gusset formats.

What add-ons can I use?

Typical options include degassing valves, zippers, tear notches, hang holes, and handle holes. (Select by product and retail display.)

Which materials are common for side gusset pouches?

Mono-PE (#4), mono-PP (#5), and compostable laminations are widely used, and match the film path to barrier and end-of-life goals.

Are side gusset pouches recyclable or compostable?

Recyclability often refers to mono-material PE (#4) or PP (#5); compostable options exist (industrial/home). Check local acceptance.

Do I need a valve for coffee?

If your coffee releases gas after roasting, a one-way valve helps vent CO₂ and protect aroma/freshness.

Can you print on side gusset pouches (and how many colors)?

Yes—digital suits fast multi-SKU work, gravure is common for large runs and controlled color builds. (Color limits vary by method.)

What products are side gusset pouches best for?

Dry goods with higher fills—coffee, tea, grains, powders, kibble, and treats—where capacity and vertical panels matter.

Get a Quote & Side Gusset Packaging Advice

Share your brief in one message. We’ll review specs, suggest a film path, and confirm timelines.