Single-material PE rollstock aimed at curbside-style recycling where supported. EVOH options can elevate barrier while staying mono-PE.

Roll Stock Film Packaging for Your Line

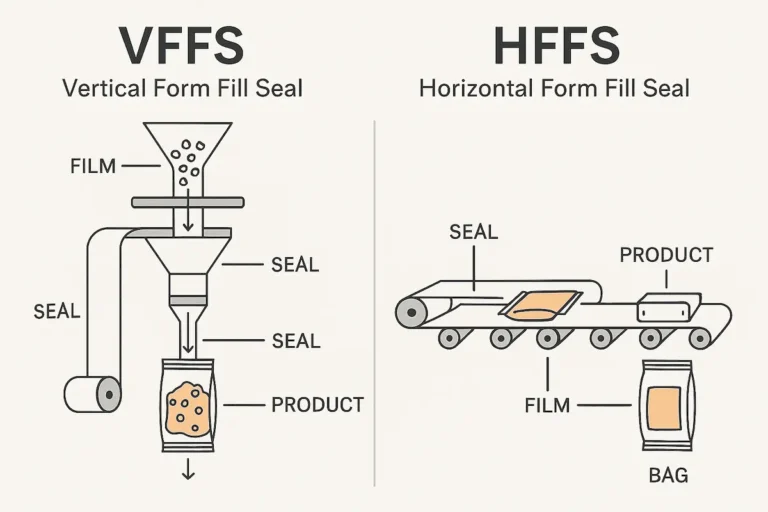

Custom-printed rollstock optimized for VFFS/HFFS lines with fast turnarounds and recyclable options—clear specs, smooth onboarding, and reliable production support.

VFFS/HFFS Ready

Artwork-to-Press Guidance

Food-Contact Compliant

What Is Roll Stock Film Packaging?

A continuous web of flexible film designed for automated VFFS/HFFS lines—ideal for speed, consistent seals, and lower unit costs.

VFFS

Vertical form-fill-seal for powders, granules, and many snacks. Prioritize web width, forming collar fit, and fin/lap seal performance.

HFFS

Horizontal form-fill-seal for bars, flow-wrap, and sachets. Check cold-seal vs heat-seal, registration marks, and repeat consistency.

Rollstock is printed and slit into precise web widths, then rewound in the correct orientation for your equipment. On line, the film forms, fills, and seals into pouches or sachets in one continuous process—reducing handling and changeovers versus premade bags. Material choices align with barrier targets (OTR/WVTR), finishes, and seal types (fin or lap; heat or cold seal). Getting orientation right prevents downtime and waste, so we provide a quick setup guide and sample runs when needed. If you’re integrating with a co-packer, we’ll translate their spec into web width, repeat, core size, and max OD to ensure day-one compatibility.

FFS Compatibility Essentials

A quick reference for VFFS/HFFS setup—what to verify before ordering rollstock.

Must-check on the line

- Forming collar & forming tube fit

- Web width vs forming set, bag length vs repeat

- Fin/Lap seal jaw temperature, dwell & pressure window

- Registration marks detection and tracking

- Roll OD/weight within unwinder limits

Must-check on the line

- Infeed pitch & lane guides set correctly

- Sealing jaws (heat/cold): dwell & pressure window

- Registration marks & pitch length consistency

- Fin/Lap seam geometry and location

- Film slip/static management on flow-wrap

Orientation & Rewind

- Sealant layer facing In/Out is specified.

- Web direction agreed: Top / Right / Bottom / Left First.

- Registration mark location relative to repeat length.

- Ink side / lamination side documented (print outside/inside).

- Longitudinal seam type/location (Fin / Lap).

- Unwind direction matches co-packer requirement.

Top First · In

Right First · In

Bottom First · In

Left First · In

Top First · Out

Right First · In

Bottom First · Out

Left First · In

Directional guidance only. Always confirm with your line or co-packer.

Web width

Printed web’s slit width entering the forming set.

Repeat

One package length on the web, ties to registration marks.

Core / Max OD

Inner core diameter (3"); max roll outer diameter allowed.

Seal Type

Fin or lap geometry for the longitudinal seal.

Seal Method

Heat-seal or cold-seal system used on the line.

Orientation

Sealant layer In/Out and web direction (Top/Right/Bottom/Left First).

Rollstock Film Materials, Finishes & Sustainable Options

Compare recyclable and compostable structures alongside conventional high-barrier roll stock engineered for VFFS/HFFS performance.

Polypropylene-based roll stock that balances stiffness and clarity; suitable for recycling programs with PP streams.

Clear, good machinability for snacks and flow-wrap. A dependable rollstock laminate for many flexible packaging lines.

Workhorse structure balancing print fidelity and seal performance across diverse product categories.

Metalized layer boosts barrier for oxygen/moisture sensitive products. Note microwave and metal detection constraints.

Bio-based rollstock for brands prioritizing compostable messaging; typically suited to industrial composting—verify local acceptance.

Industry Solutions for Roll Stock Film Packaging

Built for brand and operations teams evaluating roll stock film packaging. Explore category-specific approaches with typical structures, line considerations, and readiness tips for VFFS/HFFS lines.

Coffee & Tea

Protect aroma with high-barrier laminations and keep brand texture with matte or soft-touch finishes. If you use one-way valves, align rewind orientation and eye marks with the applicator. Set slip for smooth forming on the VFFS collar and verify seam location against key artwork.

Snacks & Bars

Run flow-wrap at speed with clear films that show the product while keeping seals consistent. Cold-seal helps protect heat-sensitive fillings and shortens dwell time on multi-up lanes. Confirm repeat length and registration control to prevent drift across long shifts.

Pet Food & Treats

Choose robust laminations for heavier fills and larger formats where puncture resistance matters. Map gusset folds and tear notches so seams avoid critical graphics and open cleanly. If you use metallized barrier, verify your metal detection path during QA.

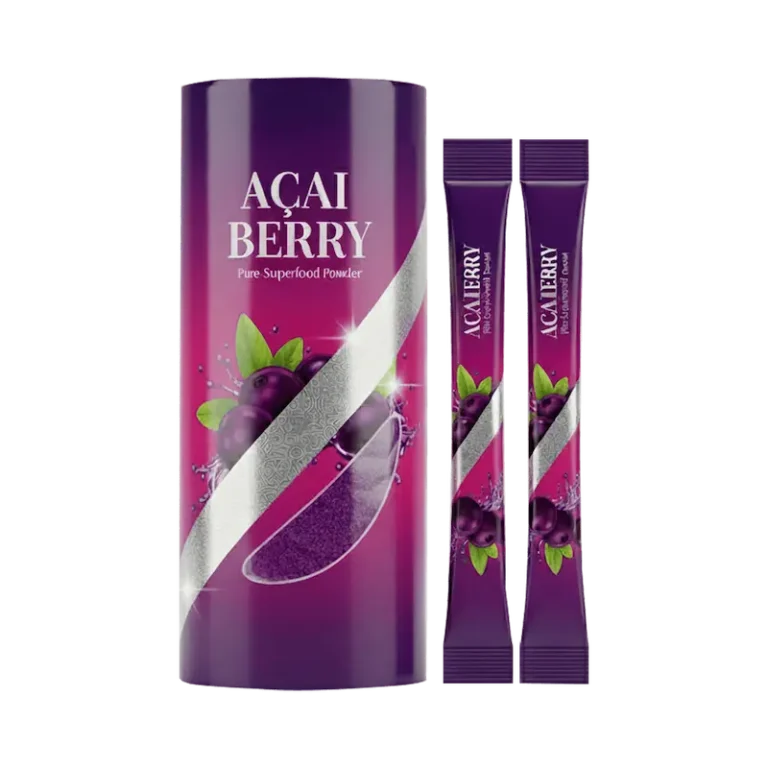

Nutraceuticals & Powders

Stick-packs and sachets need clean seals and accurate dosing with repeat matched to the cavity length. Keep powder away from the jaws to maintain seal integrity and reduce rework. Choose easy-open notch styles and confirm the ink side for consistent registration.

Rollstock Film FAQ

What is rollstock film packaging?

Rollstock is flexible packaging film supplied on a roll. On VFFS or HFFS equipment it forms, fills, and seals into pouches, sachets, or flow-wraps.

Is rollstock a fit for my VFFS/HFFS line?

Yes, when specs match your forming set and registration control. We align web width, repeat, seam style, and orientation with your operator or co-packer.

Which specs should I lock before ordering?

Confirm web width, repeat length, core size, max OD, seal type (fin or lap), seal method (heat or cold), rewind orientation (sealant in or out), and eye-mark location.

What lead times do you offer?

Typical timing is ~10–15 business days for digital and ~15–22 business days for plate-based after artwork approval. Expedite options may be available depending on materials and queue.

Do you support short runs and scale?

Yes. Use digital for pilots, seasonal SKUs, and fast turns. Move to plate-based for larger volumes while keeping approved color targets.

Do you provide sample runs or press proofs?

Yes. We support sample kits and trial runs to validate sealing windows, COF targets, and registration before full production.

Can you print variable data or integrate lot codes?

Yes. Digital supports variable data. We reserve clear areas for coding and place registration marks to match your sensors.

What is the MOQ?

Digital has flexible minimums for pilots and small batches. Plate-based production carries higher minimums due to plates and setup. We quote based on structure, width, and footage.

Ready to Run Roll Stock Film Packaging on Your VFFS/HFFS Line?

Share your web width, repeat, core size, and rewind orientation. We’ll match rollstock film structures for flexible packaging and return a fast, production-ready quote.