Flat Pouch — 3-Side Seal & Fin-Seal, Built for Food-Grade Packing

Custom flat pouches engineered for single-serve snacks, coffee sample packs, pet treats, powders, and small parts—clean profiles, reliable seals, print-ready artwork support.

- Digital 1,000 • Gravure 5,000 (per design)

- 15–22 days production

Attach artwork (if any) and your target date—we’ll respond with spec guidance and a production window.

Who Flat Pouches Are For

Made for operations and procurement teams at SMB–mid brands and co-packers who value predictable specs and fast reviews.

Single-serve snacks and promo runs without over-packaging

Coffee sample packs that travel flat and seal cleanly

Pet treats in compact formats with easy-open options

Powders and small parts needing leak-resistant seals

Pilot batches and multi-variant launches that benefit from short runs

Share net weight and filling method—we’ll align seal geometry to your line and product.

Flat Pouch Formats: 3-Side Seal & Fin-Seal

Two proven geometries—choose by product, seal strength, and line-fit.

3-Side Seal Flat Pouch (sachet)

Fin-Seal Flat Pouch

Not sure which format fits? Share details in the Quote Form and we’ll recommend a starting spec.

Why Choose Us for Flat Pouch

Four practical advantages that shorten reviews, control risk, and keep launches moving.

Lower MOQs that still scale

Digital from 1,000 pcs per design for pilots and variants. Gravure from 5,000 pcs for sustained runs—so you can validate, then ramp without re-sourcing.

Recyclable & compostable options

Mono-PE #4 and mono-PP #5 recyclable paths, plus industrial/home-compostable choices. We’ll map materials to your use-case during quoting.

Transparent samples & timelines

Free existing samples (you pay shipping), typically dispatched in 1–3 business days. Custom print prototypes require a proofing fee, refundable based on final order size.

Built-in engineering advice

Actionable guidance on sizing, sealing, and barrier selection—share net weight, product traits, and filling method, we’ll return a practical spec, not just a price.

Ask for OTR/WVTR guidance during quoting—we’ll share typical ranges for your product category.

Flat Pouch Materials & Sustainability

Food-safe films with recyclable mono-PE #4 and mono-PP #5 options, plus industrial/home-compostable paths tailored to your product.

Recyclable paths

Choose mono-PE #4 or mono-PP #5 structures for brand-friendly recycling routes where available.

Compostable options

Industrial and home-compostable materials for single-serve formats and sample runs.

Barrier guidance

Recommend a stack for oils, moisture-sensitive powders, or aroma-rich products, typical OTR/WVTR ranges are shared during quoting.

Inks & adhesives

Food-grade inks and adhesives used, documents available on request via the quote.

Unsure which film to choose? Tell us your shelf life and route in the Quote Form, we’ll recommend a stack and share typical OTR/WVTR ranges in your quote.

Flat Pouch Printing & Finishes

Choose Digital for agility or Gravure for scale—both optimized for clean registration and food-grade inks.

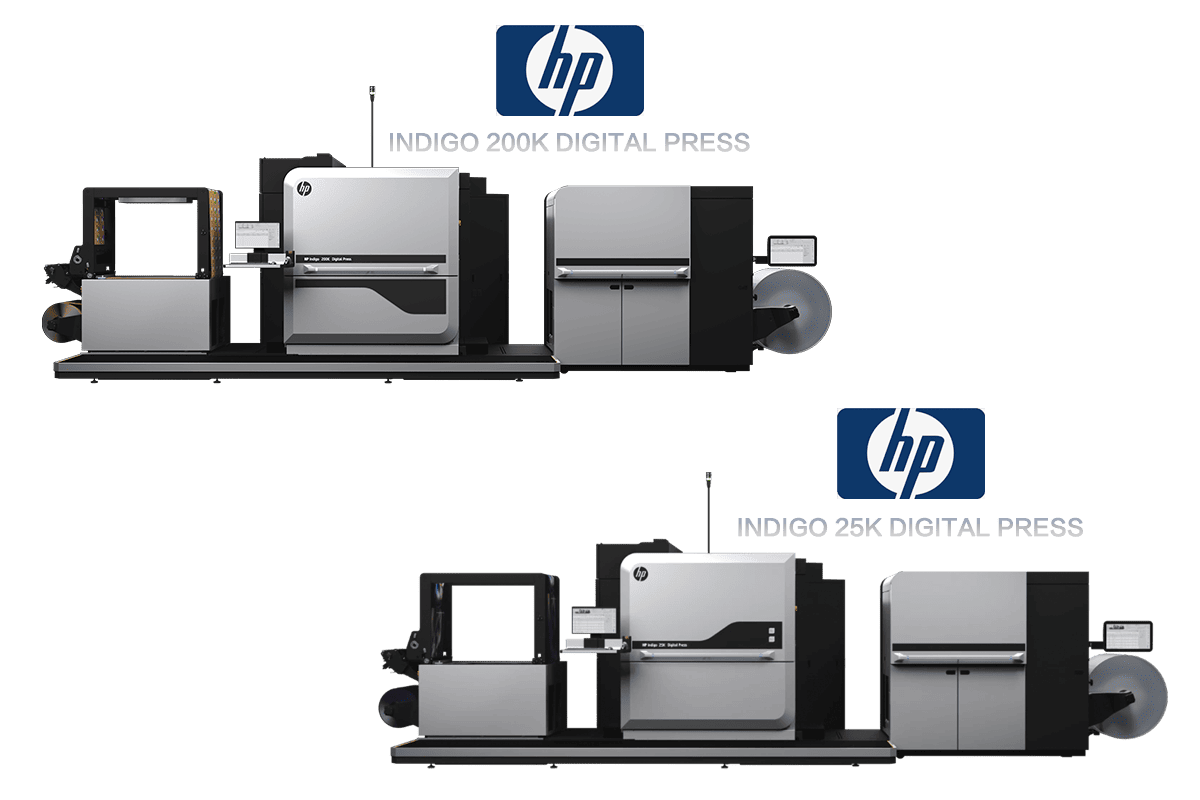

Digital printing

Unlimited colors, fast artwork changes and versioning.

Ideal for pilot batches, multi-SKU launches, and seasonal runs.

Gravure printing

Up to 9 colors (CMYK + spot) with metallic inks and Pantone support.

Economical for sustained volumes and long shelf programs.

Request dielines and print specs with your quote—we’ll return the template that fits your Flat Pouch size and seal geometry. See Dielines or use the Quote Form.

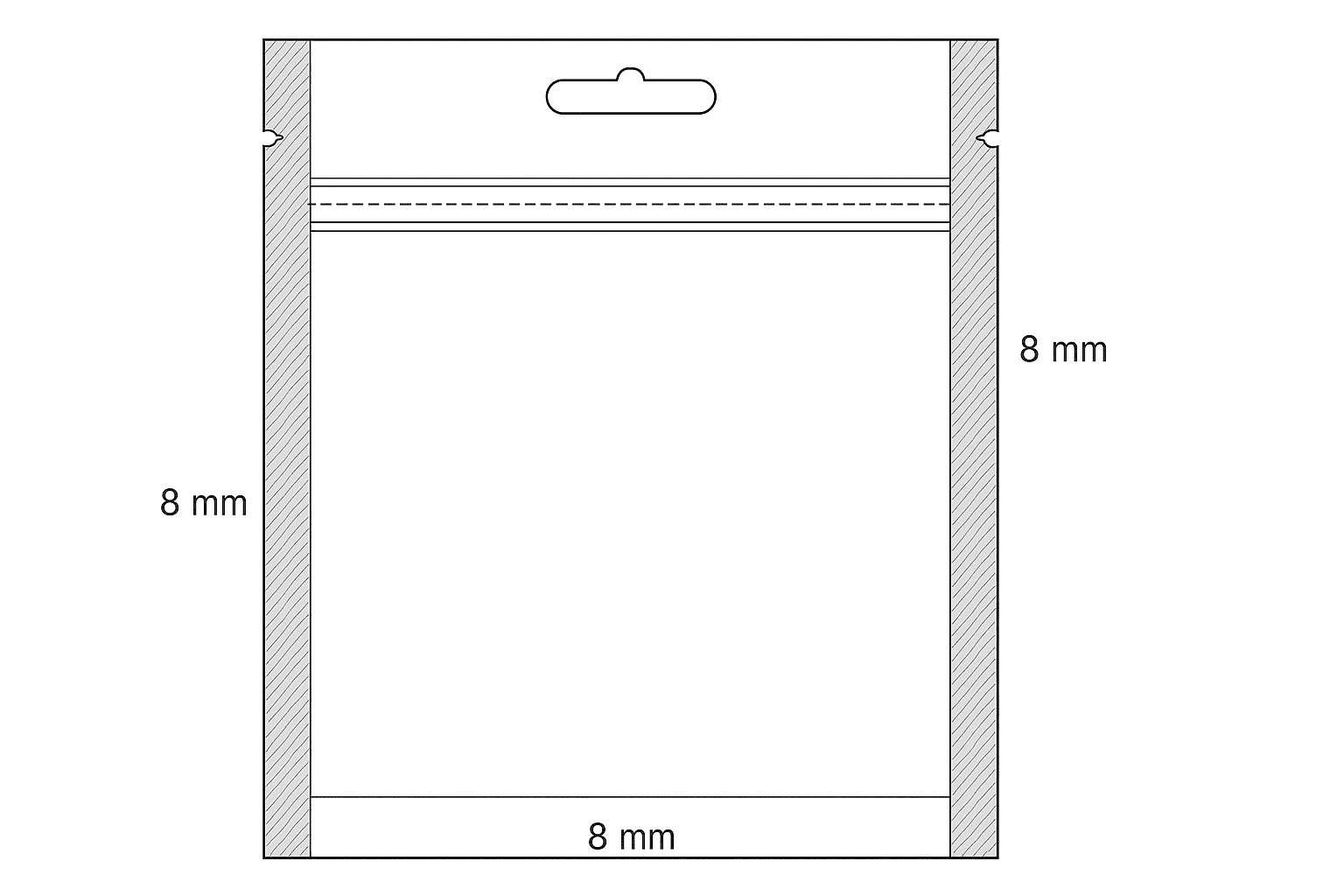

Flat Pouch Engineering & Specs

Quick Spec

Turn your net weight into a working Flat Pouch spec—size, film gauge, and seal geometry aligned to your product and line.

- Size target → outer frame proposal

- Film gauge confirmed at quote stage

- Features: Hang hole / Tear notch / Rounded corners / Easy-open

- 3-Side vs Fin-Seal guidance for which market / speed / orientation

Need a dieline for artwork? Request it with your quote—see Dielines or use the Quote Form.

Size & Thickness

Share the intended net weight and target footprint, we’ll propose an outer frame and fill path you can review quickly.

Features

Pick essentials only. We prioritize machinability and QC.

Sealing & Filling Fit

Heat-seal windows and orientation for faster checks on the line.

Illustration — Net Weight → Outer Frame

Flat Pouch Samples & Prototypes

Evaluate materials and print fast—choose existing samples or a custom print prototype.

Request

Use the Quote Form and choose Existing Samples or Custom Print Prototype.

Existing samples are free—you cover shipping. Prototypes include a proofing fee that may be refunded based on final order size.

Provide

Share your product, net weight, target size, material path (mono-PE #4 / mono-PP #5 or compostable), format (3-Side or Fin-Seal), and receive-by date.

For prototypes, include artwork (or WIP) and brand colors, we’ll return the dieline you need.

Receive

Existing samples: film swatches and recent Flat Pouch examples; typical dispatch 1–3 business days.

Prototypes: a printer-ready proof and a production window aligned to your launch.

Samples and prototypes are for evaluation. Compliance/testing documents are available on request.

Flat Pouch Lead Time & MOQs

The numbers you need for planning.

15–22 days

Production (excluding transit)

1,000 pcs

Digital MOQ per design

5,000 pcs

Gravure MOQ per design

Have a fixed receive-by date? Add it in the Quote Form and our team will confirm rush capacity.

Flat Pouch Compliance & Certifications

We support the programs below. Tell us what your retailer or QA team requires and we’ll attach the current documents to your quote.

Need a specific test or certificate? Name the program in the Quote Form and we’ll confirm availability and turnaround.

Flat Pouch FAQ

Practical answers for sizing, sealing, materials, and reviewing.

What is a Flat Pouch in flexible packaging?

A Flat Pouch is a pre-made flexible pack that lies flat when filled. The two common Flat Pouch formats are 3-Side Seal (sealed on three sides, filled from the open side) and Fin-Seal (a longitudinal back fin with top/bottom seals).

Flat Pouch vs. Stand-Up Pouch — what’s the difference?

Flat Pouches are optimized for slim profiles, samples, and fast line speeds. Stand-Up Pouches add a gusset so the pack can stand on shelf. Choose Flat Pouch when you need compact, mail-friendly formats or flow-wrap compatibility.

3-Side Seal vs. Fin-Seal Flat Pouch — how do I choose?

Use 3-Side Seal for simple filling, small counts, and powders that benefit from strong edge control. Choose Fin-Seal when your line favors back-fin construction and higher throughput. Share product flow and line speed and we’ll recommend a fit.

Are Flat Pouches recyclable or compostable?

Yes. We offer recyclable mono-material paths—mono-PE #4 and mono-PP #5—and industrial/home-compostable options. “Compostable kraft” refers to regular kraft (not recycled pulp). Local recycling acceptance varies, tell us your route and we’ll align materials.

What do OTR and WVTR mean for Flat Pouch barriers?

OTR (oxygen transmission rate) and WVTR (water-vapor transmission rate) indicate how much oxygen/moisture passes through a film under standard test conditions. We share typical ranges during quoting based on your product and shelf-life targets.

How do I size a Flat Pouch for my net weight?

Tell us the product, intended net weight, and target footprint. We’ll propose an outer frame and fill path you can review quickly. Film gauge is confirmed at quote stage to balance seal strength, stiffness, and cost.

Which features can a Flat Pouch include?

Common options include hang hole, tear notch, rounded corners, and easy-open placements. We recommend only what the line needs to keep machinability and QC strong.

Can Flat Pouches handle powders without leaks?

Yes—by pairing the right seal geometry with an appropriate film gauge and consistent heat-seal windows (time/temperature/pressure). We can send existing samples or a prototype for validation before you scale.

Are Flat Pouches food-safe for my application?

Yes—food-contact documentation can be attached to your quote on request. We use food-grade inks and adhesives and can provide the records your QA or retailer needs.

Flat Pouch vs. Pillow Pack — are they the same?

No. Flat Pouches are pre-made packs supplied as individual units, while Pillow Packs are typically formed-fill-seal on the line with fin and end seals. If you’re unsure which route fits your equipment and product, tell us your filling method and we’ll guide you.

Can Flat Pouch materials support window cutouts and matte finishes?

We provide typical ranges during quoting once we know your product and shelf-life targets. Publishing a fixed table can be misleading without context, we’ll return values appropriate to your use-case.

Ready to spec your Flat Pouch?

Send a few details—we’ll return a practical spec, the right dieline, and a clear production window.