Mylar bags are praised for long-term food storage1—but are they still the best option as packaging tech evolves?

Mylar bags can preserve dry food for up to 30 years, especially in 7 mil thickness with oxygen absorbers2. However, sustainable industrial pouches3 now rival Mylar in shelf life, automation, and compliance.

If you’re in food manufacturing or emergency preparedness, you’re likely familiar with Mylar. But as global regulations and consumer demands shift toward sustainability and automation, it’s worth asking: is Mylar still the top choice?

While 7 mil Mylar bags can preserve low-moisture foods for up to 30 years, industrial-scale recyclable or compostable barrier pouches offer comparable performance with greater sustainability and automation efficiency4.

Let’s break down the facts so you can make an informed decision.

Understanding Mylar Bag Construction and Barrier Properties

Outdated materials can compromise food safety5 and shelf life.

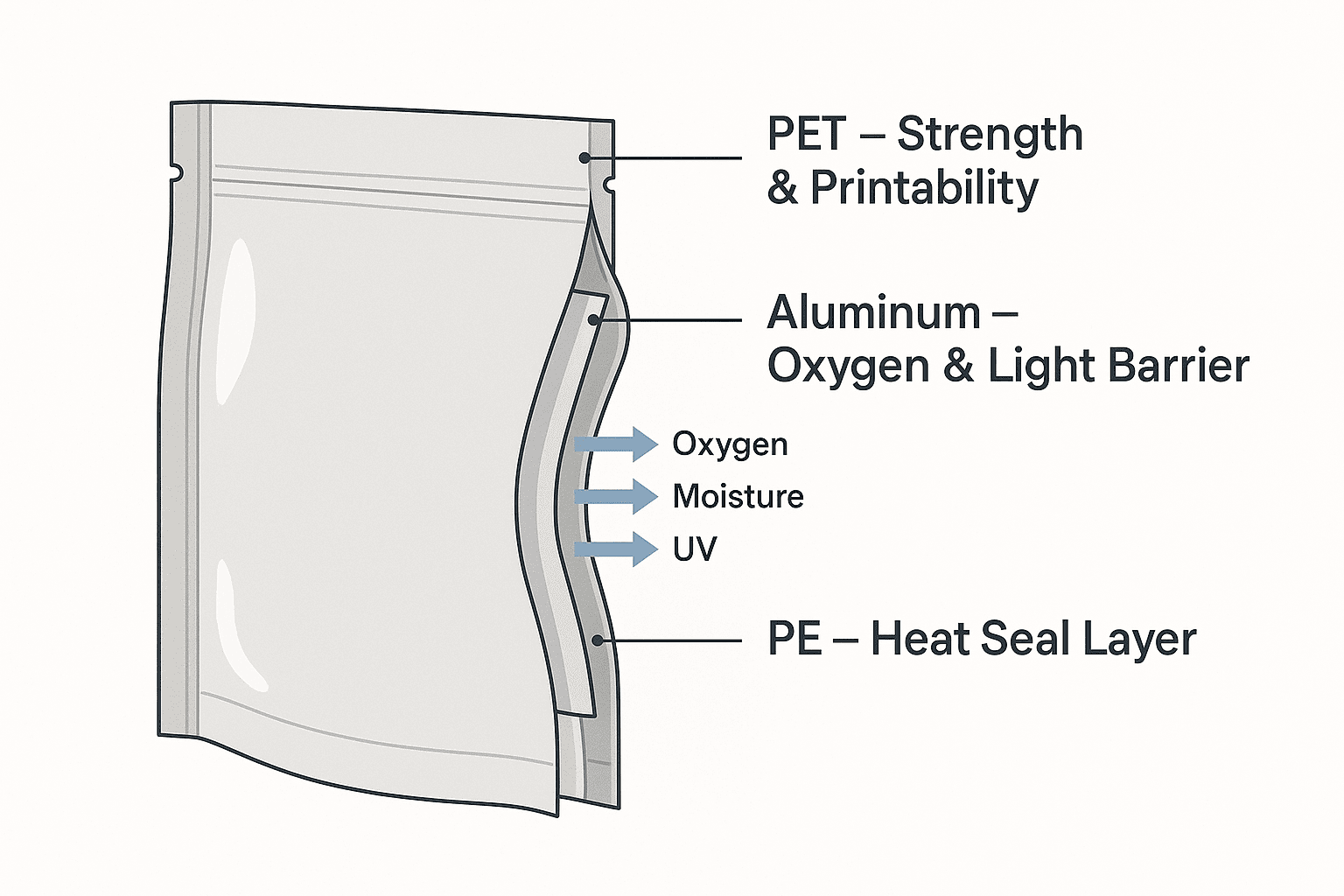

Mylar bags are made from PET films with aluminum layers, offering high oxygen and moisture barriers through heat sealing.

What is Mylar? PET films, aluminum layering, and heat sealing

The term "Mylar" refers to biaxially-oriented polyethylene terephthalate (BoPET) film. It’s typically laminated with aluminum foil and sometimes further layered with polyethylene (PE) for sealability. This structure creates a durable, flexible barrier ideal for dry food storage.

Here’s a common 3-layer Mylar construction:

| Layer | Material | Function |

|---|---|---|

| Outer | PET | Strength, printability |

| Middle | Aluminum Foil | Oxygen, light barrier |

| Inner | PE | Heat sealable, food-contact |

The result is a pouch that can be easily heat sealed and stored in various conditions.

Barrier performance: Oxygen transmission rates (OTR) and moisture control6

Oxygen and moisture are the two main culprits in food degradation. Mylar bags achieve near-zero OTR and extremely low moisture vapor transmission rates (MVTR), especially when aluminum foil is used.

Typical OTR values for aluminum-laminated Mylar are <0.01 cc/m²/day. This makes them suitable for preserving nutrients and preventing oxidation over long periods. Combined with proper sealing and oxygen absorbers, these properties are the foundation of Mylar’s long shelf life7.

Shelf Life: Comparing 4 Mil vs 7 Mil Mylar Bags

Using thin Mylar bags for long-term storage can risk punctures and spoilage.

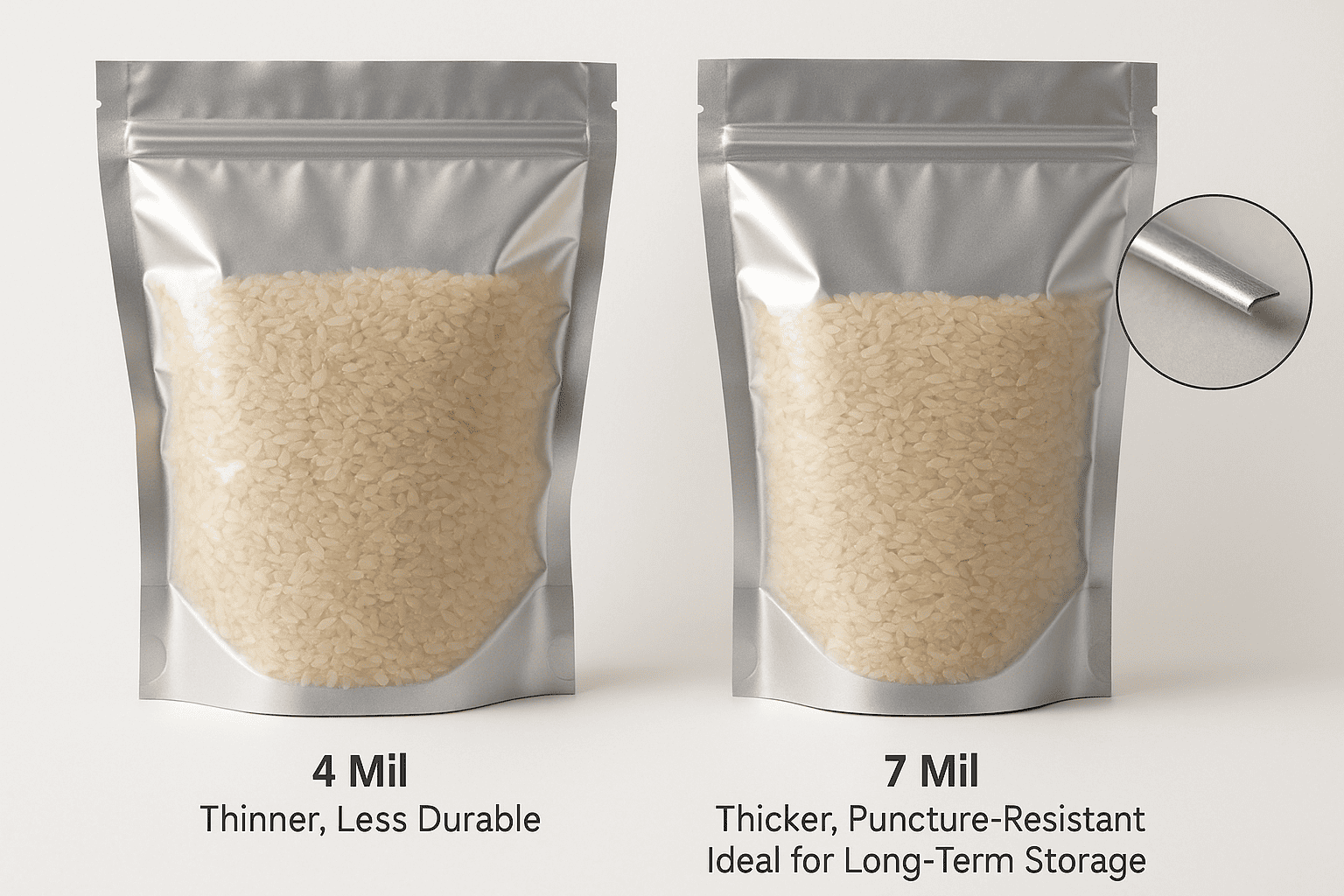

7 mil Mylar bags8 provide better puncture resistance and longer shelf life than 4 mil, especially for 25+ year storage of low-moisture foods.

Thickness and durability: Why 7 mil matters for 25+ year storage

The thickness of Mylar bags directly impacts their durability, barrier integrity, and resistance to light and punctures. Here’s why it matters:

- 4 mil bags: Suitable for short to medium-term storage. Easier to seal but more prone to damage.

- 7 mil bags: Thicker and tougher, ideal for long-term storage (20–30 years) and better for stacking or rough handling.

If you’re storing food in bulk or for emergency rations, 7 mil is the industry standard.

Real-world shelf life data for low-moisture foods

When paired with oxygen absorbers, 7 mil Mylar bags can preserve low-moisture foods like:

- White rice: Up to 30 years

- Pasta: 20–25 years

- Dried beans: 25+ years

- Powdered milk: 10–15 years

In my experience working with emergency food suppliers, the success of long-term storage comes down to proper sealing, low humidity during packing, and correct oxygen absorber usage.

Oxygen Absorbers and the Science Behind Food Preservation

Without oxygen absorbers, even the best packaging can fail over time.

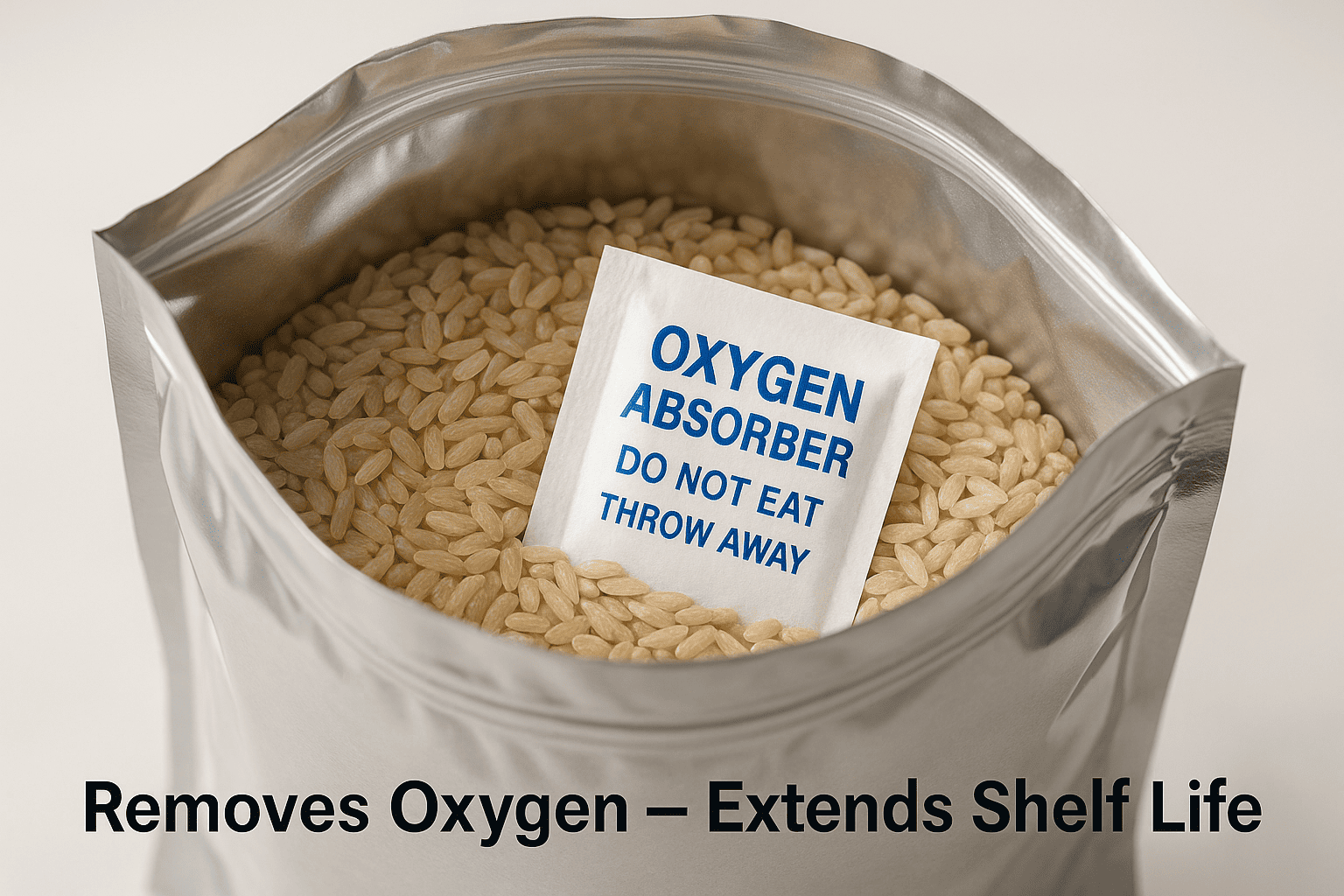

Oxygen absorbers remove residual oxygen inside Mylar bags, preventing oxidation, microbial growth, and nutrient loss.

How oxygen absorbers work and proper dosage calculation

Oxygen absorbers contain iron powder that reacts with oxygen and moisture to form iron oxide, effectively removing O₂ from sealed environments.

To calculate the right amount:

- Measure the internal volume of the bag.

- Estimate residual oxygen (typically 20% of air volume).

- Choose an absorber rated in cc—common sizes are 100cc to 2000cc.

For example, a 1-gallon Mylar bag usually needs a 300–500cc absorber, depending on headspace.

Impact on oxidation, microbial growth, and nutrient retention9

Removing oxygen slows down:

- Oxidation: Prevents rancidity in fats and oils.

- Microbial growth: Inhibits aerobic bacteria and mold.

- Nutrient loss: Especially vitamins A, C, and E.

This is why oxygen absorbers2 are critical, especially for foods like nuts, grains, and dehydrated meals. I often advise clients to avoid overusing absorbers, as they can cause package collapse and affect product presentation.

Regulatory Compliance: FDA and BRCGS Standards for Flexible Packaging

Non-compliant packaging can derail production and lead to costly recalls.

Food-grade packaging must meet FDA and BRCGS standards, including traceability, GMP, and documentation for food contact safety.

What food-grade means in industrial contexts

“Food-grade” isn’t just a marketing term—it refers to compliance with food contact safety regulations. In the U.S., the FDA defines which materials are safe for indirect food contact (CFR Title 21). In Europe, it’s EC Regulation 1935/2004.

For flexible packaging like Mylar, compliance typically includes:

- Use of FDA-approved resins

- Migration testing

- Certification letters from suppliers

I always recommend getting documentation early in the sourcing process to avoid delays during audits.

Traceability, GMP, and documentation requirements

BRCGS and other global standards require:

- Lot traceability: From raw material to finished product

- GMP (Good Manufacturing Practices): Cleanrooms, pest control, hygiene

- COA and Declarations of Compliance: Certifying the pouch is food-safe

At PackagingBest, our production lines follow BRCGS protocols, and we provide full documentation for every roll and pouch we ship.

Mylar vs. Industrial-Grade Sustainable Packaging

Relying only on Mylar may limit your brand’s sustainability goals.

Compostable and recyclable barrier pouches now offer similar protection to Mylar with reduced environmental impact.

Performance comparison: Compostable and recyclable high-barrier pouches

Modern sustainable pouches have come a long way. Some options include:

- Recyclable PE/PE or PP/PP mono-materials: Good oxygen and moisture barriers, compatible with recycling streams.

- Compostable PLA or paper-film laminates: For short- to mid-term storage.

Here’s a quick comparison:

| Feature | Mylar | Recyclable PE | Compostable PLA |

|---|---|---|---|

| OTR | <0.01 | ~0.1–0.5 | ~1.0 |

| MVTR | Excellent | Good | Moderate |

| Shelf Life | 20–30 yrs | 1–10 yrs | 6–18 months |

| Automation | Moderate | High | Moderate |

For dry foods under 2-year shelf life7, sustainable pouches are absolutely viable.

Environmental impact and corporate sustainability metrics

Many of our clients now report packaging KPIs such as:

- Carbon footprint per pouch

- Recyclability score

- Post-consumer resin (PCR) content

Choosing recyclable or compostable pouches helps meet ESG goals, reduce plastic tax liabilities, and appeal to eco-conscious consumers.

Automation Compatibility and Operational Efficiency

Manual sealing is slow and inconsistent—Mylar isn’t always automation-friendly.

Mylar bags can work in semi-automated lines, but industrial pouches3 are designed for faster, more reliable filling and sealing.

How Mylar performs in automated fill-seal systems

Mylar was never designed for modern form-fill-seal (FFS) machines. Challenges include:

- Stiffness and memory: Harder to form consistently

- Seal inconsistency: Especially when using thicker materials

- Static issues: Attract dust and reduce cleanroom performance

Some high-end systems can handle Mylar, but with slower speeds and higher error rates.

Advantages of purpose-built industrial pouches for throughput and sealing integrity

Industrial-grade pouches, especially PE-based or co-extruded films, are:

- Formable: Optimized for pouch shape and line speed

- Seal-friendly: Uniform surfaces for ultrasonic or heat sealing

- Customizable: Zippers, valves, and spouts added inline

That’s why many of our clients in snack foods and freeze-dried meals are switching to recyclable pouches—they save time and reduce waste on the line.

Key Considerations for Food Manufacturers and Emergency Brands

Clinging to outdated packaging can hinder growth and compliance.

Use Mylar for long-term, low-volume storage. Transition to sustainable pouches for automation, branding, and eco mandates.

When to use Mylar vs. when to transition to sustainable options

Here’s a quick decision guide:

| Use Case | Mylar | Sustainable Pouch |

|---|---|---|

| Emergency food (25+ yrs) | ✅ | ❌ |

| DTC subscriptions (under 2 yrs) | ❌ | ✅ |

| Retail snack packs | ❌ | ✅ |

| Government rations | ✅ | ❌ |

| Automated lines | ⚠️ | ✅ |

If your goal is long-term storage with minimal handling, Mylar still works. But if you’re scaling production or targeting eco-conscious markets, it’s time to evolve.

Cost-benefit analysis: Shelf life, automation, and compliance

While Mylar might seem cheaper upfront, consider:

- Labor costs: Manual sealing vs automated lines

- Waste: Reject rates from poor seals

- Regulatory risks: Lack of documentation or recyclability

Sustainable pouches may cost slightly more per unit but often reduce total cost of ownership through better efficiency and brand alignment.

In summary, while Mylar still excels at long-term storage, modern flexible packaging offers smarter, greener options for today’s food brands.

Ready to evaluate sustainable alternatives to traditional Mylar bags8?

Request free samples of our industrial-grade recyclable and compostable barrier pouches to see how they compare in performance, automation compatibility, and compliance with your food safety5 requirements.

-

Learn about the effectiveness of Mylar bags in preserving food for extended periods. ↩

-

Discover the science behind oxygen absorbers and their role in food preservation. ↩ ↩

-

Find out how industrial pouches can offer similar benefits to Mylar with added sustainability. ↩ ↩

-

Find out how automation can enhance efficiency in food packaging operations. ↩

-

Explore the essential food safety standards that packaging materials must meet. ↩ ↩

-

Learn about the importance of moisture control in maintaining food quality. ↩

-

Discover the key factors that determine the shelf life of various food items. ↩ ↩

-

Explore the advantages of Mylar bags for long-term food preservation and their unique properties. ↩ ↩

-

Understand the role of packaging in preserving the nutritional value of food. ↩