Custom Frozen Food Packaging Bags & Pouches

High-barrier flexible pouches for vegetables, seafood, dumplings and ready meals — freezer-safe, leak-resistant and shelf-ready.

- Freezer-safe barrier

- SKU-matched pouches

- Low MOQ, fast lead

The Freezer Is Tough on Your Packaging

Frozen aisles mean low temperatures, moisture, and rough handling — if packaging fails, product quality and brand perception suffer.

Freezer burn & dehydration

Air and moisture in the freezer cause ice crystals, color changes and dried-out textures when barriers are weak.

Cracks, leaks & broken seals

Low temperatures can make poor films brittle, so impacts and stacking in the cold chain can split seals, corners and gussets.

Foggy, off-smelling packs

Condensation and odor transfer cloud clear windows, dull graphics, and let strong freezer smells invade your products.

That’s why the first step is format fit — we match your frozen SKUs to the right pouch shape for filling, stacking and display. Explore pouch formats

Flexible Frozen Food Pouch Formats

Stand Up Pouch

Stand-up pouches are one of the most common formats in the frozen aisle and offer excellent brand visibility plus resealable convenience for vegetables, fruits, snacks and seafood pieces.

Lay Flat Pouch

Simple, cost-effective flat packs sealed on three sides, ideal for dumplings, seafood fillets, meat cuts and frozen snacks that are packed flat and stacked tightly in cartons or freezers.

Square Bottom Pouch

Stand upright and hold more volume, making them perfect for heavier or family-size frozen mixes, seafood and value packs where shelf stability and large branding panels matter.

How We Engineer Frozen Food Packaging That Actually Works

We start from your frozen products and cold-chain conditions, then recommend film laminations and pouch details that help prevent freezer burn, cracking and leaks.

Start with Your Frozen Products and Channels

We look at what you’re packing — vegetables, seafood, dumplings or ready meals — plus portion size, filling temperature, storage time, and where your frozen food packaging will be sold — from retail freezers to foodservice and e-commerce.

Translate risks into film and seal specs

Based on those details, we choose proven high-barrier laminations using PET, nylon and PE, then set thickness and seal requirements so your pouches resist freezer burn, moisture, oxygen and low-temperature cracking.

Add freezer-friendly features where they matter

Where needed, we add anti-fog and odor-control films to keep windows clear and graphics sharp, and specify sealant layers, zippers and tear notches that can survive your cold-chain filling, stacking and transport.

Send us your frozen product details — we’ll recommend the pouch format, film lamination and seal specs within 24 hours.

Frozen Food Packaging for Key Categories

We tailor pouch formats and film specs to each frozen product so your packaging survives the cold chain and looks great in the freezer aisle.

Frozen Vegetables & Fruits

Meat, Poultry & Seafood

Dumplings, Noodles & Asian Foods

Ready Meals & Entrées

Frozen Snacks & Bakery

Freezer-Aisle Shelf Impact & Design Support

We make your frozen food packaging stand out in frosty, low-light freezers and stay clear, on-brand and easy to shop.

Bold, freezer-ready visuals

High-contrast layouts, appetizing imagery and clear windows are designed for the frozen aisle, so shoppers spot your pouches quickly even behind glass and frost.

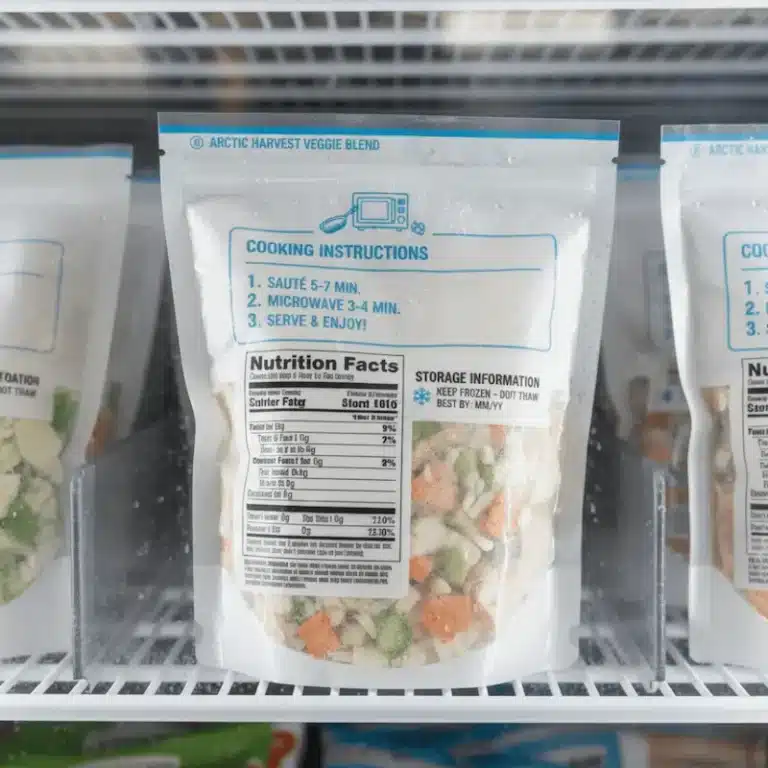

Clear information at a glance

We reserve space and hierarchy for cooking steps, storage guidance and nutrition so key details stay legible on small packs and busy freezer doors.

Dielines & artwork checks

You get accurate pouch dielines, pre-print checks and feedback on logo, color and layout, so printed pouches match the design your team signs off on.

Flexible for Startups and Growing Frozen Food Brands

Whether you’re launching your first frozen SKU or scaling a full range, we make frozen food packaging decisions simpler and less risky.

Start small, scale with confidence

We support smaller runs and phased rollouts, so you can test new frozen products, adjust designs and gather feedback before committing to larger volumes.

Hands-on support for busy teams

You get clear guidance on pouch formats, film choices and features like zippers or windows, plus print-ready dielines and artwork checks so your team doesn’t have to figure it all out alone.

Built around your markets

We tailor specs to where you sell — from retail freezers to foodservice and e-commerce — balancing performance, shelf impact and cost for each SKU.

Launching or refreshing a frozen line? Share your products and goals and we’ll recommend a packaging plan that fits your stage of growth.

From Brief to Frozen-Ready Pouches in 4 Steps

Share your frozen products and goals

Tell us what you’re packing — vegetables, seafood, dumplings, ready meals or snacks — plus fill weight, filling temperature, storage time and sales channels.

Get a pouch proposal and quote

We match your SKUs to pouch formats and film laminations, then send you a clear quote, lead time and, if needed, sample options.

Approve dielines, artwork and specs

You review and approve dielines, graphics and key specs such as pouch size, thickness, zippers and tear notches before we start production.

Production, quality checks and delivery

We manufacture your frozen food packaging pouches, run quality checks and ship according to the agreed schedule so you can launch or switch packs with confidence.

Ready to start a frozen food packaging project? Share your product details and we’ll respond within 24 hours.

Frozen Food Packaging FAQs

What is the best packaging for frozen food?

There isn’t one single “best” format. For most frozen products we recommend high-barrier pouches made from multi-layer PET, nylon and PE, with the pouch format matched to how your products are filled, stacked and displayed in the freezer.

How do your pouches help reduce freezer burn?

We use film laminations with strong moisture and oxygen barriers, combined with freezer-grade sealant layers and tight seals. This helps limit air movement, ice crystal growth and surface dehydration that lead to freezer burn.

Which pouch format should I choose for my frozen products?

Stand-up pouches work well for many retail frozen vegetables, fruits, snacks and ready meals. Lay-flat / three-side-seal pouches are ideal for dumplings, meat cuts and seafood fillets, while flat-bottom pouches suit heavier or family-size packs — we’ll recommend formats based on your specific SKUs.

What information do you need to recommend a structure and quote?

We usually ask about your product type, fill weight, filling temperature, storage time, target markets and sales channels, plus whether you need features like zippers or windows. With those details, we can recommend pouch formats, film laminations and give you a clear quotation.

Are your materials safe for frozen meat and seafood?

Yes. We use food-contact grade films, inks and adhesives suitable for frozen meat and seafood applications, and can provide supporting documentation on request.

What are your typical MOQs and lead times for frozen food pouches?

MOQs and lead times depend on pouch size, film structure and printing requirements. We support smaller runs for new or seasonal frozen SKUs and will confirm a realistic MOQ and schedule once we understand your project.

Do you offer recyclable or compostable frozen food packaging?

At the moment we focus on conventional high-barrier laminations for frozen food packaging, as they provide the most reliable performance in cold-chain conditions. If you’re exploring more sustainable options for other product categories, we’re happy to discuss what’s possible.

Custom Frozen Food Packaging Bags Made for Your Products

Share your frozen SKUs, packing conditions and channels — we’ll recommend pouch formats, film laminations and timelines tailored to your brand.