Your logo looks perfect on the screen, but will it survive the reality of coffee packaging? Most roasters learn this lesson the hard way.

Yes, you can absolutely customize coffee bags with your brand logo. The process involves selecting the right bag structure, ensuring proper barrier properties for freshness (targeting less than 2cc oxygen transmission rate), choosing appropriate printing methods1 (digital for under 5,000 units, rotogravure for larger runs), and testing seal integrity at your specific altitude and storage conditions before finalizing your design.

Here’s what nobody tells you at trade shows: stunning graphics mean nothing if your technical specifications fail. I’ve watched too many brands invest thousands in beautiful designs only to recall entire batches because they overlooked critical technical details.

What technical specifications should I prioritize before adding my logo?

Beautiful logos can’t save coffee that tastes stale. The brutal truth? Your packaging’s invisible features matter more than what customers see.

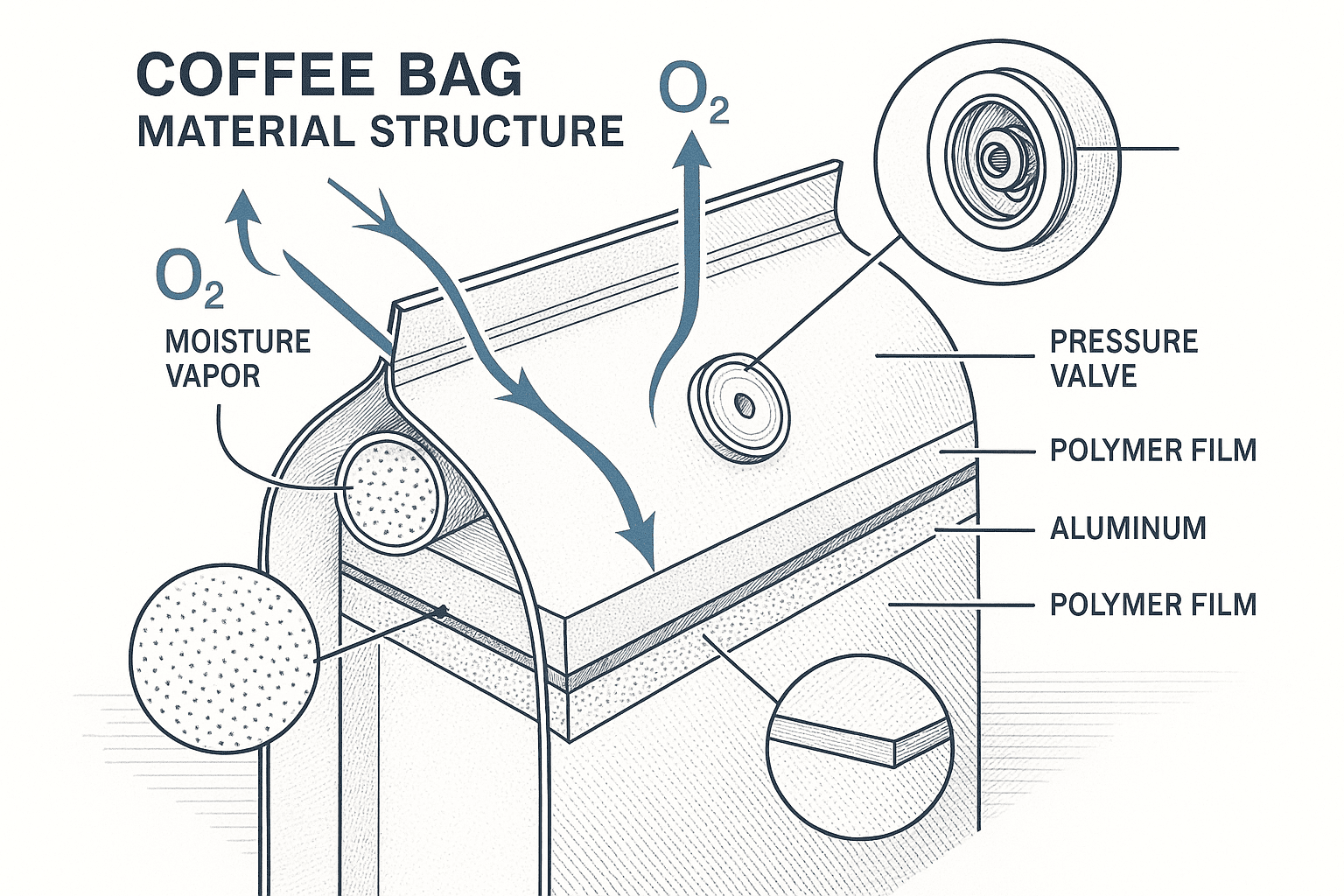

Before adding your logo, prioritize these specifications: oxygen transmission rate2 below 2cc/m²/24hr, moisture vapor transmission rate3 under 0.5g/m²/24hr, degassing valve4 with 0.5-1.0 PSI cracking pressure, and heat seal strength5 exceeding 2.5 lbs/inch. Test these at your storage altitude and temperature range. Only after validating these specs should you focus on logo placement and design.

I learned this lesson personally when a client blamed our "defective bags" for their stale coffee complaints. Their gorgeous four-color logo was perfect, but they had specified the cheapest barrier film against our technical recommendations. After lab testing proved our bags met their inferior specs exactly, they finally understood that beautiful packaging means nothing without proper barrier properties6. The experience taught me that function creates trust, while graphics only create first impressions.

Critical Barrier Properties

Your coffee releases CO2 for weeks after roasting. Without proper barriers, oxygen sneaks in while CO2 escapes. This creates stale coffee faster than you think. I recommend multi-layer structures with aluminum or EVOH barriers for optimal protection. My clients typically use a 120-micron structure combining PET/AL/PE or PET/EVOH/PE.

Valve Selection Matters

Not all valves work equally. Cheap valves fail at altitude changes during shipping. They either stay closed (causing bags to burst) or stay open (letting oxygen flood in). Look for valves tested at various altitudes with consistent cracking pressure between 0.5-1.0 PSI.

Seal Integrity Testing

Heat seals fail silently. You won’t know until customers complain about stale coffee. Test your seals at maximum fill weight plus 20% safety margin. Run drop tests from 3 feet height. Check seal strength after 48 hours of degassing. These simple tests prevent disasters.

How do I choose between digital and rotogravure printing for my logo?

Your print method determines both quality and cost. Choose wrong, and you either overpay or get poor results.

Digital printing works best for runs under 5,000 bags, offering lower setup costs ($200-500) and 2-week turnarounds. Rotogravure printing becomes cost-effective above 10,000 bags, providing superior color consistency and metallic effects but requiring $2,000-5,000 in cylinder fees and 6-8 week lead times. Digital allows easy design changes; rotogravure locks you into one design.

[^7] comparison Comparison of digital vs rotogravure printing on coffee bags](https://www.packagingbest.com/wp-content/uploads/2025/09/Comparison-of-digital-vs-rotogravure-printing-on-coffee-bags.png)

The printing method affects more than just appearance. It impacts your entire business model.

Digital Printing Advantages

Digital printing lets you test designs quickly. You can run seasonal editions without massive commitments. Color matching reaches 95% accuracy with modern HP Indigo presses. The ink sits on top of the material, creating sharp details perfect for QR codes and fine text. Small roasters love digital because they can order exactly what they need.

Rotogravure Benefits

Rotogravure creates unmatched quality for large runs. The ink embeds into the material, producing rich, consistent colors that won’t fade. Metallic effects and spot varnishes look premium. Once you make the cylinders, per-unit costs drop significantly. I suggest rotogravure when clients commit to a design for at least 12 months.

Hidden Printing Considerations

Both methods have limits. Digital struggles with exact Pantone matching on metallic substrates. Rotogravure requires minimum order quantities that might force excess inventory. Consider your cash flow and storage space before choosing. Also check if your printer uses food-safe, low-migration inks that won’t transfer flavors to your coffee.

What bag formats work best for branded coffee packaging?

Bag format affects everything from shelf presence to customer experience. Wrong choice here undermines your entire brand strategy.

Stand-up pouches dominate specialty coffee (60% market share) due to excellent shelf visibility and 12-16oz capacity. Flat bottom bags offer premium positioning with maximum stability and billboard-like branding space. Side gusset bags provide traditional appeal and efficient shipping but less shelf impact. Choose based on your retail environment, price point, and target customer expectations.

Each format serves different business goals. Understanding these differences prevents costly mistakes.

Stand-Up Pouches for Flexibility

Stand-up pouches balance cost and performance perfectly. They use less material than box pouches while maintaining excellent shelf presence. The bottom gusset expands for stability. Customers appreciate the resealable zippers. I typically recommend starting with stand-up pouches7 because they work everywhere – retail shelves, e-commerce shipping, and farmer’s markets.

Flat Bottom Bags for Premium Positioning

Flat bottom bags scream premium. They stand tall and proud on shelves, creating a luxury feel. The five panels offer massive branding space. They stack efficiently in shipping boxes. However, they cost 20-30% more than stand-up pouches. Use flat bottom bags8 when targeting high-end markets or when competing against established premium brands.

Side Gusset Bags for Traditional Markets

Side gusset bags connect with traditional coffee consumers. They fold flat for efficient shipping, reducing logistics costs by 30%. Roasters appreciate the classic look. But they don’t stand independently, requiring shelf fixtures or laying flat. Choose side gusset bags9 for wholesale accounts, office coffee services, or markets valuing tradition over innovation.

How much should I budget for custom coffee bag development?

Real costs extend beyond printing. Most roasters underestimate total investment by 40-60%.

Budget $3,000-8,000 for initial custom coffee bag development including design ($500-2,000), prototype sampling ($300-800), plate/cylinder fees ($0-5,000 depending on print method), initial order (1,000-10,000 bags at $0.35-0.85 each), and testing/validation ($500-1,500). Add 20% contingency for revisions. Ongoing orders cost $0.25-0.65 per bag depending on volume and specifications.

Smart budgeting means understanding both upfront and hidden costs. Many expenses surprise first-time buyers.

Design and Development Costs

Professional design costs $500-2,000 but saves money long-term. Good designers understand print limitations, preventing costly revisions. They create files optimized for your chosen print method. Prototype sampling runs $300-800 for 3-5 iterations. This seems expensive until you consider the cost of 10,000 wrong bags. Never skip prototyping – it catches problems before mass production.

Production Variables

Minimum order quantities affect unit pricing dramatically. Ordering 1,000 bags might cost $0.85 each while 10,000 bags drop to $0.35 each. Special features add cost: zippers ($0.08-0.15), valves ($0.15-0.25), tear notches ($0.03-0.05). Material upgrades for better barriers add $0.10-0.20 per bag. Calculate total landed cost including shipping, customs, and warehousing.

Testing and Validation Investment

Testing seems optional until problems arise. Spend $500-1,500 on proper validation: accelerated aging tests, seal strength analysis, valve performance checks, print durability testing. This investment prevents recalls, protects reputation, and ensures consistent quality. I’ve seen brands skip testing only to face $50,000+ losses from failed packaging.

Common Questions About Custom Coffee Bag Branding

1. Can I change my design after ordering?

Digital printing allows design changes between orders with minimal cost. Rotogravure requires new cylinders ($2,000-5,000) for any changes. Plan designs for 12-18 month cycles minimum.

2. What file formats do I need for printing?

Provide vector files (AI, EPS, PDF) with fonts outlined, 300 DPI resolution, and 3mm bleed. Include Pantone color references. Convert RGB to CMYK for accurate color reproduction.

3. How do I protect my brand from copycats?

Register trademarks before printing. Add security features like QR codes linking to authentication pages. Use unique bag structures or special effects difficult to replicate. Document your packaging for legal protection.

4. What’s the typical lead time for custom bags?

Digital printing takes 2-3 weeks after approval. Rotogravure needs 6-8 weeks including cylinder production. Add shipping time: 7-10 days air freight, 30-45 days ocean freight. Plan accordingly for seasonal launches.

Conclusion

Custom coffee bags with your logo require balancing technical excellence with visual appeal. Focus first on barrier properties, seal integrity, and valve selection. Choose print methods based on volume and flexibility needs. Test thoroughly before mass production. This approach ensures your brand looks great while keeping coffee fresh.

-

Discover the pros and cons of various printing methods to make an informed decision for your brand. ↩

-

Learn about the importance of oxygen transmission rates in coffee packaging to ensure quality. ↩

-

Explore the importance of moisture control in coffee packaging to maintain quality. ↩

-

Learn about the role of degassing valves in preserving coffee freshness. ↩

-

Discover the necessary heat seal strength to ensure your coffee bags remain intact. ↩

-

Understanding barrier properties is essential for maintaining coffee freshness; this link provides valuable insights. ↩

-

Learn about the advantages of stand-up pouches and how they can enhance your brand’s visibility. ↩

-

Discover how flat bottom bags can elevate your coffee brand’s presentation and stability. ↩

-

Understand the traditional appeal of side gusset bags and their suitability for certain markets. ↩