You grab a bag of chips from the shelf. The package looks shiny and modern. You wonder where it goes after you finish the snacks.

Traditional potato chip bags1 are not recyclable in most municipal systems. These bags use multi-layer films combining aluminum and plastic that cannot be separated by standard recycling facilities. The crinkle test confirms this: crush the bag in your hand, and if it springs back to its original shape, it goes to landfill. Only specialized programs like TerraCycle2 accept certain snack packaging, but these represent less than 1% of actual chip bag waste.

This simple answer hides a complex reality. The packaging industry sells you labels that say "recyclable" or "eco-friendly3." But those labels don’t tell you what happens in your local recycling center. I’ve watched companies switch to "sustainable" packaging only to face higher product damage rates and rejected shipments. The gap between marketing claims and operational reality costs real money.

Why Are Traditional Chip Bags Not Recyclable?

Most people think chip bags fail recycling because companies don’t care. That’s wrong. The design serves a critical purpose.

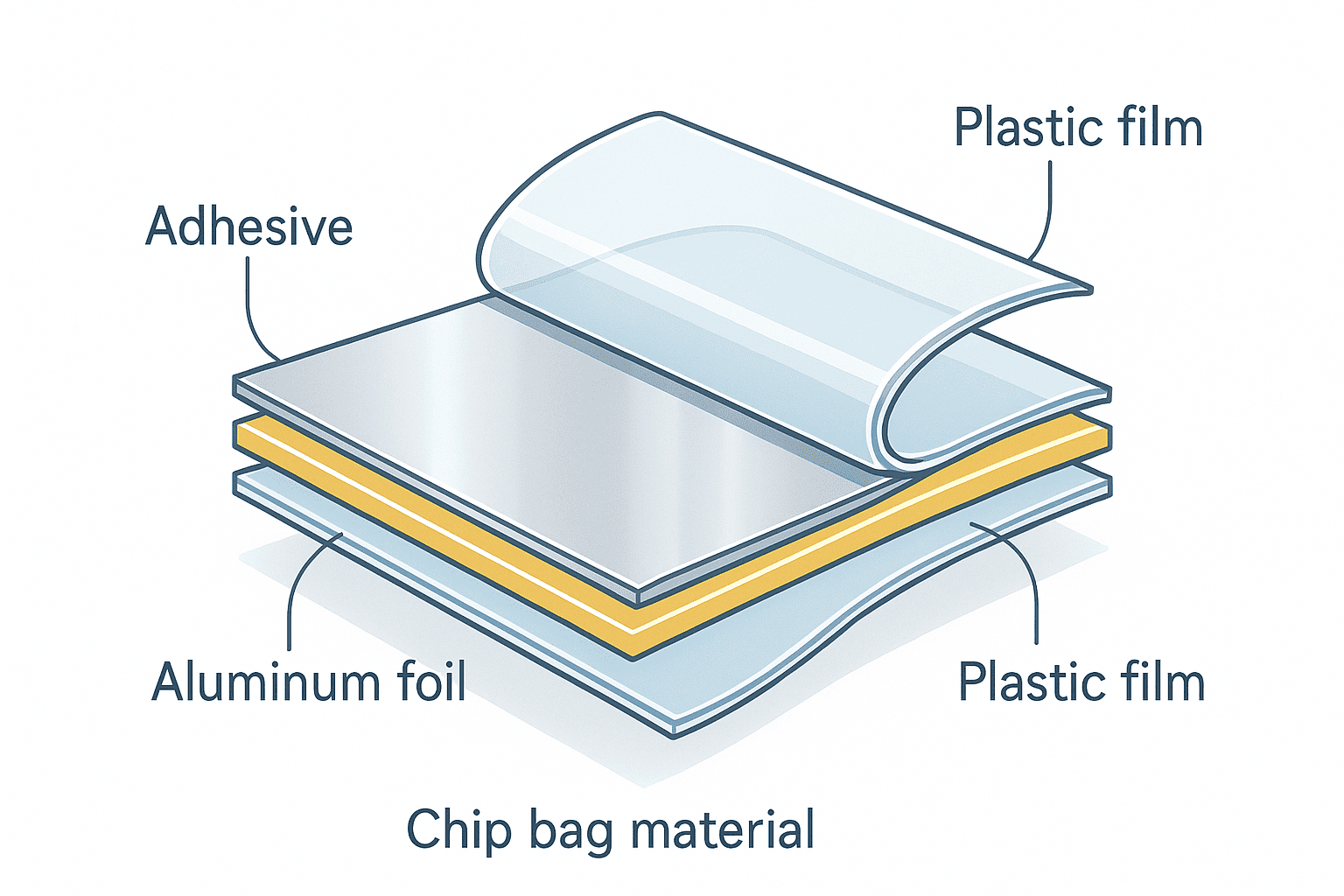

Chip bags use multi-layer structures (typically metallized film with plastic layers) because they need three essential barriers: oxygen protection, moisture resistance, and light blocking. A single-material structure cannot provide all three barriers effectively. This multi-layer construction bonds aluminum with various plastics (often BOPP, PE, or PET) through lamination processes that make the layers inseparable during standard recycling.

Potato chips oxidize rapidly when exposed to air. A fresh chip loses its crunch within hours without proper packaging. The fat content in chips makes this worse. Manufacturers need to guarantee shelf life of 6-12 months from production to consumption.

Traditional paper cannot provide this protection. Plastic alone allows too much oxygen transmission. Glass and metal work but cost too much and weigh too much for shipping economics. This pushed the industry toward laminated films combining aluminum’s barrier properties with plastic’s flexibility and sealing capability.

What Does "Eco-Friendly" Actually Mean on Packaging?

You see these labels everywhere now. "Sustainable packaging." "Recyclable materials." "Compostable film." Companies use these terms freely. But what do they mean in practice?

"Eco-friendly" on packaging has no standardized legal definition in most jurisdictions. A package can claim eco-friendly status based on one small component while the rest remains non-recyclable. The Federal Trade Commission’s Green Guides require environmental claims to be substantiated, but enforcement is limited. What matters more than the label is whether the packaging can be processed through existing waste infrastructure in the regions where it will be discarded.

The Certification Gap

I reviewed certification requirements for major environmental claims. Here’s what I found: A package can be certified "recyclable" if the material type is theoretically recyclable, even if no facility within 100 miles of the consumer accepts it. A bag can claim "compostable" if it meets ASTM D6400 standards in industrial composting4 conditions that most municipalities don’t offer.

The disconnect gets worse with "biodegradable" claims. This term has no timeline requirement in many regions. A bag that breaks down in 500 years under specific conditions can technically be called biodegradable.

What B2B Buyers Should Actually Ask

When you evaluate packaging suppliers5, skip the marketing terms. Ask these specific questions instead:

What percentage of municipal recycling programs in your target markets actually accept this material? Get data, not promises. Request zip code level information for your primary distribution areas.

What is the real-world composting rate for this material? Not lab conditions – actual consumer composting data6. If the supplier cannot provide this, the claim is probably marketing.

What happens to product integrity7 during the extended supply chain? A bag that is technically recyclable but causes 40% more product damage doesn’t solve your problem. It creates a bigger one by increasing overall waste.

Can You Recycle Chip Bags Through Special Programs?

Some companies offer take-back programs. These sound good in theory. Let’s look at how they work in practice.

TerraCycle and similar programs accept specific snack packaging through mail-in recycling. Participants collect used bags, package them, and ship them to processing facilities. However, participation rates remain below 2% of total snack packaging waste. The process requires consumer effort that most people won’t make, and shipping generates its own environmental cost. These programs handle specialty recycling that municipal systems cannot, but they don’t scale to solve the broader problem.

The Economics of Take-Back Programs

I analyzed the cost structure of these programs. The economics only work when subsidized by the brand manufacturer. For every pound of packaging collected, the program costs $3-8 in collection, sorting, and processing. Compare this to landfill costs of $0.05-0.15 per pound.

Brands use these programs for marketing value, not environmental impact at scale. They can point to the program in sustainability reports. But when I asked program managers for actual recovery rates, the numbers were tiny. One major snack brand’s program recovered less than 0.3% of their packaging waste.

The programs require too many steps. A consumer must: save used bags, accumulate enough to justify shipping, find a shipping box, print a label, go to a post office, and mail the package. Each step loses 50-80% of the people who intended to participate.

What Are the Real Alternatives for Snack Packaging?

This brings us to the critical question for anyone sourcing packaging: what actually works? Not what sounds good in presentations, but what survives real supply chains while meeting environmental goals.

Viable alternatives for snack packaging must balance four factors: product protection, supply chain durability8, end-of-life processing capability, and total system cost. Mono-material recyclable films show promise but currently require process modifications that many co-packers resist. Compostable films work in theory but need industrial composting infrastructure that most regions lack. The most practical path forward for most brands involves recyclable PE-based structures that existing curbside programs can handle, though these require oxygen scavengers or vacuum packaging to maintain product quality.

Mono-Material Recyclable Structures

Several suppliers now offer all-PE (polyethylene) structures for snack packaging. These can go into existing plastic film recycling streams. The catch: they provide inferior barrier properties compared to metallized multi-layer films9.

Some manufacturers solve this with higher-tech PE films incorporating nano-barriers or special coatings. These work better but cost 40-60% more than traditional metallized film. For high-margin products, this is feasible. For commodity snacks competing on price, it kills the margin structure.

Compostable Film Reality Check

Compostable films made from PLA or PBS materials generate lots of marketing buzz. I recommend caution here. These materials require industrial composting at temperatures of 140-160°F for 45-90 days. How many of your customers have access to industrial composting?

According to BioCycle’s data, only about 185 industrial composting facilities in the US accept compostable packaging. That covers roughly 8% of the population. In most zip codes, these "compostable" bags end up in landfills where they don’t actually compost due to lack of oxygen and proper conditions.

I suggest a simple test: before choosing compostable packaging, map your customer zip codes against actual industrial composting access. If less than 50% of your volume goes to areas with access, you’re selling marketing, not solutions.

The Paper-Based Packaging Trap

Some brands switch to paper-based bags to look more sustainable. Paper feels natural to consumers. But paper alone cannot protect chips. So manufacturers add plastic or wax coatings. This creates the same separation problem as metallized plastic – you now have mixed materials.

I’ve seen companies launch paper chip bags with great fanfare, only to quietly switch back within 18 months due to product quality complaints. The chips arrive stale. Return rates spike. Customer satisfaction drops.

If you choose paper packaging, verify what happens to it in municipal recycling streams. Most curbside programs reject wax-coated or plastic-lined paper. It contaminates the paper recycling stream.

How Should Wholesale Buyers Evaluate Packaging Solutions?

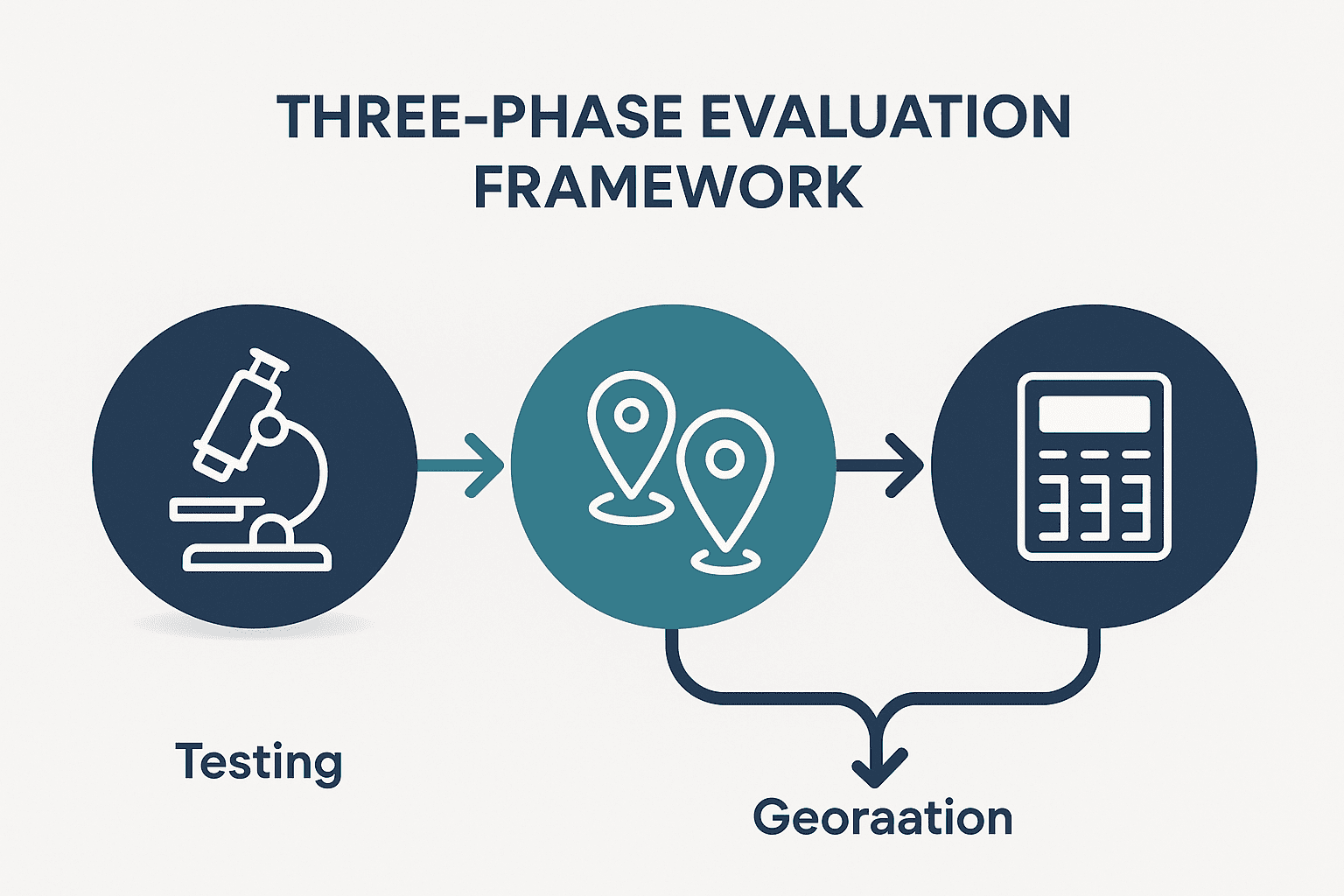

You’re responsible for sourcing packaging for thousands or millions of units. Marketing claims don’t help you. You need a framework for real decisions.

Evaluate packaging solutions through a three-phase testing protocol: First, pilot test materials with your actual filling equipment and products for at least 6 months to verify quality consistency. Second, map end-of-life infrastructure availability across your distribution footprint using zip-code level data. Third, calculate total system cost including product damage rates, not just unit packaging price. Most importantly, establish relationships with waste management10 directors in your key markets, not just sustainability consultants who don’t handle actual waste streams.

Phase 1: Real-World Production Testing

I recommend running pilot programs before committing to alternative packaging. Work with your co-packer to test new materials on actual production lines, not just hand samples.

When you test, monitor these metrics: line speed capability, seal failure rates, filling accuracy, and package consistency. A material that works at 30 bags per minute but fails at 120 bags per minute doesn’t work for scaled production.

Get samples from three different production runs separated by time. Some materials show consistency issues as raw material batches change. You want to catch this before placing orders for millions of units.

Phase 2: Infrastructure Mapping

This step separates serious sustainability efforts from greenwashing. Map where your products actually get consumed. Get data at the zip code level if possible, at minimum by metro area.

Contact waste management companies in those areas. Ask specific questions: Do you accept this material in curbside pickup? What happens to it after collection? Where does it go? What percentage actually gets recycled versus landfilled?

Phase 3: Total System Cost Analysis

Don’t just compare packaging unit costs. Calculate total system impact.

A cheaper "recyclable" package that causes 15% more product damage costs you more money overall. You’ve now wasted both the packaging AND the product inside. The environmental impact is worse, not better.

Factor in these elements: packaging unit cost, product damage rates, shipping weight and volume, disposal costs, and brand reputation impact.

Building Relationships That Matter

Here’s what most people miss: the most valuable relationship is not with your packaging supplier’s sustainability consultant. It’s with the waste management director in your largest markets.

These people know what actually happens to packaging. They can tell you which materials work and which cause problems. They often know about infrastructure changes before they’re publicly announced.

I suggest scheduling calls with waste management directors in your top 5 markets once per year. Ask them what they need from packaging designers. Their answers will guide better decisions than any trade show presentation.

How Do Different Market Segments Handle This Issue?

Requirements and solutions vary significantly across product categories and markets. What works for premium organic chips differs from commodity snacks.

Premium and specialty snack brands can justify 30-50% higher packaging costs11 because their margin structure allows it and their customers expect environmental leadership. Mass market brands need solutions that add no more than 5-10% to packaging costs due to competitive price pressures. B2B buyers should segment their approach: use advanced sustainable materials for premium lines while focusing on incremental improvements and infrastructure development for value products.

Premium Segment Strategy

If you sell organic chips, gourmet popcorn, or artisan snacks at $4-8 per bag, you have options. Your customers actively seek sustainable packaging12 and will pay for it.

I recommend recyclable mono-material structures or compostable films13 for this segment, even with their limitations. Partner with How2Recycle or similar labeling programs to clearly communicate disposal instructions. Consider offering take-back programs or partnering with TerraCycle.

Your packaging can become a brand differentiator. But be specific in your claims. Say "recyclable where store drop-off programs exist" rather than just "recyclable." Your educated customers will appreciate the honesty.

Mass Market Segment Approach

For mainstream chips competing with national brands at $2-3 per bag, the economics are tighter. You cannot add 50% to packaging costs without losing shelf space.

Focus on incremental improvements rather than complete material changes. Switch to structures with higher recycled content even if not fully recyclable. Use thinner gauge films that maintain barrier properties but reduce material use. Optimize package sizes to reduce waste.

These changes won’t get press releases, but they create real impact at scale. A 15% reduction in material use across 100 million packages prevents more waste than a perfect compostable package used for 1 million units.

Regional Market Differences

North American, European, and Asian markets have different infrastructure and regulations. Your packaging strategy should account for these differences.

European markets generally have better recycling infrastructure and stricter regulations. Materials that work in Europe often don’t work in the US yet due to infrastructure gaps. Asian markets vary widely – Japan and South Korea have sophisticated recycling but Southeast Asian countries often lack infrastructure.

If you export to multiple regions, you may need different packaging solutions for different markets. I’ve seen companies use compostable packaging in the EU and recyclable mono-material in North America for the same product. This adds complexity but matches infrastructure reality.

Frequently Asked Questions About Chip Bag Recycling

1. Can I recycle chip bags in my curbside bin?

No, in most cases. Traditional metallized chip bags are not accepted by curbside recycling programs because they contain mixed materials that cannot be separated. Check with your local waste management provider, but approximately 95% of municipal programs reject these bags. Some areas offer store drop-off programs for plastic films, but these typically exclude metallized materials.

2. What is the crinkle test for recyclability?

Crush the bag in your hand. If it springs back to its original shape, it contains layers that make it non-recyclable through standard programs. If it stays crushed, it may be accepted by plastic film recycling programs. This test works because the metal layer in traditional chip bags creates the "memory" that makes the bag bounce back.

3. Are compostable chip bags better than traditional ones?

Only if you have access to industrial composting facilities. Compostable bags require specific conditions (high temperature, proper moisture, oxygen) that only exist in industrial composting facilities. In landfills or home compost bins, they don’t break down effectively. Check if industrial composting exists in your area before assuming compostable packaging is better.

4. Why don’t companies just use recyclable materials?

Product protection requirements make this difficult. Chips need protection from oxygen, moisture, and light to stay fresh for months. Current recyclable mono-materials provide weaker barrier properties, reducing shelf life from 9-12 months to 3-6 months. This creates supply chain challenges and potentially more waste from spoiled products.

5. What happens to chip bags in landfills?

They remain essentially unchanged for hundreds of years. The multi-layer structure that protects chips from degradation also prevents the packaging itself from breaking down. The plastic and aluminum layers resist decomposition in landfill conditions. This is why finding alternatives or improving recovery systems matters.

6. Are there any chip brands using fully recyclable packaging?

Some brands now offer mono-material PE structures that are technically recyclable through store drop-off programs, though curbside acceptance remains limited. A few premium brands use compostable materials. However, as of 2025, most major chip brands still use traditional metallized multi-layer films due to performance and cost considerations.

7. Should I choose packaging based on recycled content or recyclability?

Both matter, but recyclability has bigger long-term impact. Packaging made from recycled materials reduces virgin resource use. Packaging that can be recycled reduces future waste. The ideal solution offers both. If you must choose one, prioritize recyclability in your distribution markets – packaging that can actually be recycled creates a circular system.

8. How can I verify environmental claims on packaging?

Look for third-party certifications (How2Recycle, BPI Compostable, etc.) rather than self-made claims. Contact local waste management facilities to verify acceptance. Ask suppliers for documentation of their testing methods. Be skeptical of vague terms like "eco-friendly" without specific, verifiable statements about material content and end-of-life processing.

Conclusion

Traditional chip bags are not recyclable in most systems due to their multi-layer structure. The gap between "technically recyclable" and "actually recycled" defines the real sustainability challenge. For B2B buyers, success requires testing materials in real supply chains, mapping end-of-life infrastructure in your markets, and calculating total system costs rather than just packaging unit prices. The best solution balances product protection, operational feasibility, and genuine environmental impact in the regions where your products are actually consumed.

-

Discover the truth about the recyclability of potato chip bags and their environmental impact. ↩

-

Explore TerraCycle’s innovative recycling solutions for hard-to-recycle materials. ↩

-

Find out the real meaning behind eco-friendly labels on packaging and their effectiveness. ↩

-

Find out about industrial composting facilities and their role in sustainable waste management. ↩

-

Learn how to assess packaging suppliers based on their sustainability practices. ↩

-

Learn about the relevance of consumer composting data in evaluating packaging claims. ↩

-

Understand the importance of packaging in maintaining product quality and reducing waste. ↩

-

Understand the importance of supply chain durability in selecting packaging materials. ↩

-

Learn how multi-layer films affect recycling and the challenges they pose for sustainability. ↩

-

Explore the critical role of waste management in effective recycling and sustainability. ↩

-

Discover how packaging costs affect sustainability efforts and overall environmental impact. ↩

-

Understand the concept of sustainable packaging and its implications for the environment. ↩

-

Discover the potential and limitations of compostable films in sustainable packaging. ↩