The sustainability claims on coffee packaging often hide a complex reality. Many roasters struggle to find truly eco-friendly options1 that actually work.

Custom matte laminate coffee bags can be eco-friendly, but only when all materials are compatible with the same waste stream. The key is choosing mono-material structures like PE/EVOH or compostable PLA-lined paper2. These bags must include recyclable zippers3, valves, and adhesives. Without this compatibility, even "recyclable" bags end up in landfills.

Many coffee companies want sustainable packaging4 but face real challenges. Material suppliers make confusing claims. Recycling facilities have different rules. And customers expect both quality protection and environmental responsibility. Let me share what I’ve learned about making matte laminate bags truly sustainable.

What Makes Matte Laminate Coffee Bags Different?

Matte laminate isn’t just about looks. It creates a protective barrier that keeps coffee fresh while giving bags that premium, soft-touch feel.

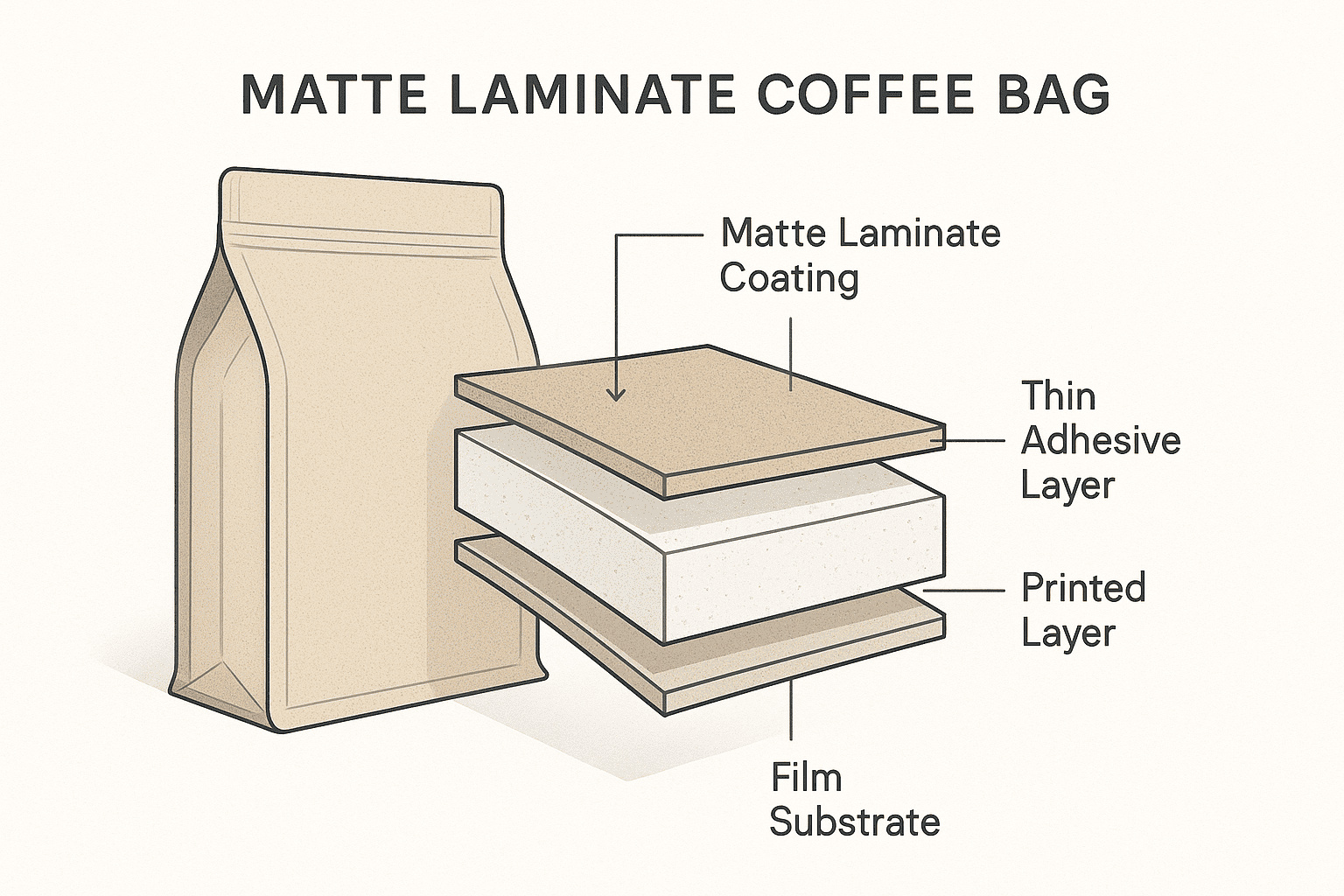

Matte lamination bonds multiple thin films together using heat and pressure. This creates a strong, flexible package with excellent barrier properties. The matte finish absorbs light instead of reflecting it, giving bags a natural, velvety texture. It also hides fingerprints and small scratches better than glossy finishes.

The lamination process starts with die-cutting the materials to size. Then manufacturers apply heat-activated adhesive to the laminate film. The printed layer and laminate pass through rollers that use heat and pressure to create a permanent bond. Finally, the laminated material goes through a curing process to set the adhesive.

I’ve seen many roasters choose matte laminate for aesthetic reasons. But the technical benefits matter more. The laminate protects printed designs from moisture and handling damage. It also strengthens the bag structure, which is important for stand-up pouches and flat-bottom bags.

The real question isn’t whether matte laminate looks good or performs well. It’s whether these bags can be recycled or composted properly. This depends entirely on material compatibility5.

Why Does Material Compatibility Matter So Much?

Most "recyclable" coffee bags fail because they mix incompatible materials. This creates contamination that ruins the recycling process.

Material compatibility means every component – the base film, laminate, zipper, valve, and adhesive – must work in the same waste stream. For example, a recyclable PE bag becomes trash if it uses a non-recyclable zipper. Studies show up to 50% of flexible plastics6 get rejected during recycling due to contamination from mixed materials.

A roaster once showed me their "eco-friendly" bags—recyclable film with standard zippers. Those zippers contaminated entire recycling batches, defeating the sustainability goal completely.

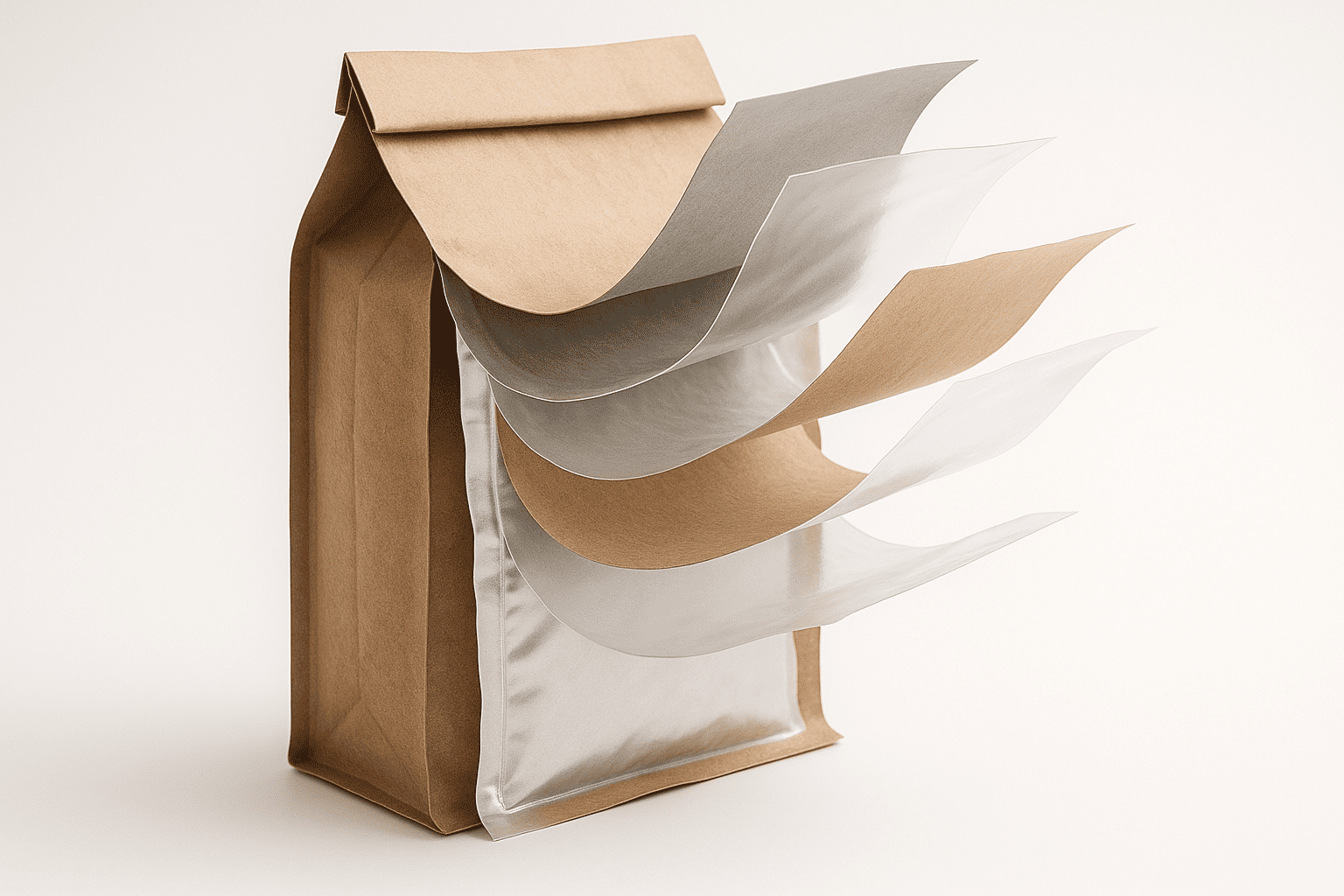

The problem starts with how bags are made. Traditional coffee bags use three or four different materials layered together. Each layer serves a purpose – moisture barrier7, oxygen barrier, strength, printability. But these multi-material structures can’t be separated for recycling.

Common Material Incompatibilities

| Component | Recyclable Option | Non-Recyclable Version |

|---|---|---|

| Base Film | LDPE, PE | Multi-layer laminates |

| Barrier Layer | EVOH (<5% by weight) | Aluminum foil, PVDC |

| Zipper | PE-based | Standard PP zippers |

| Valve | PE-compatible | Traditional PET valves |

| Adhesive | Water-based | Solvent-based |

Even small details matter. The ink affects recyclability too. Water-based inks work best because they have low VOC content and can be removed during recycling. But many printers still use solvent-based inks that contaminate the recycling stream.

I recommend mono-material structures8 for my clients who want truly recyclable bags. These use compatible materials throughout the entire package. For example, PE/EVOH structures work well when EVOH makes up less than 5% of the total weight. This maintains recyclability while providing good barrier properties.

How Can You Make Matte Laminate Bags Truly Sustainable?

Real sustainability requires choosing the right materials from the start. Green marketing claims mean nothing if the bags can’t actually be recycled.

To make sustainable matte laminate coffee bags, use mono-material structures with compatible components. Choose PE/EVOH for recyclable bags or PLA-lined paper for compostable ones. Work with suppliers who can provide full material disclosure and recycling test data9. Most importantly, verify that local facilities actually accept these materials.

I help my clients choose between two main sustainable options. The first is recyclable PE/EVOH structures10. These bags use polyethylene as the base material with a thin EVOH barrier layer. All components – including the matte laminate finish – are PE-compatible. This means the entire bag goes into the same recycling stream.

The second option is compostable bags made from kraft paper or rice paper lined with PLA. These work well for smaller volumes or specialty coffees with faster turnover. The matte finish comes from the paper texture itself rather than added laminate.

Key Factors for Sustainable Choices

Barrier Requirements: Coffee needs protection from oxygen, moisture, and light. PE/EVOH provides excellent barriers for most applications. But some specialty coffees might need additional protection.

Shelf Life Needs: Recyclable PE bags typically protect coffee for 6-12 months. Compostable paper bags work best for 3-6 month shelf lives. Choose based on your distribution timeline.

Local Recycling Infrastructure: Check what your local facilities actually accept. Many claim to recycle flexible plastics but reject laminated materials. Some areas have better composting infrastructure than recycling.

Volume and Cost: Sustainable materials often cost 15-30% more than traditional options. But prices drop with larger orders. I suggest starting with smaller test runs to verify performance before committing to large volumes.

What About Disposal and Customer Education?

Even the best sustainable packaging fails if customers don’t dispose of it properly. Clear communication makes the difference.

Successful sustainable packaging requires customer education11 about proper disposal. Print clear recycling or composting instructions directly on the bag. Include your local facility requirements. Consider offering a take-back program12 for customers who lack proper disposal options. This shows real commitment beyond marketing claims.

I’ve learned that customers want to do the right thing but need help. Many don’t know that coffee bags require special handling. They throw "compostable" bags in regular recycling or put "recyclable" bags in compost bins. Both contaminate waste streams.

Start by researching your local waste management rules. Different regions have vastly different capabilities. What works in San Francisco might not work in rural areas. Some facilities accept flexible plastics but only if they’re clean and dry. Others reject all laminated materials regardless of composition.

Print disposal instructions prominently on your bags. Use simple language and clear icons. Explain any preparation steps like removing labels or cleaning the bag. If your bags require special facilities, provide a locator tool on your website.

Some roasters create take-back programs for used bags. Customers return empty bags to the cafe or through mail. The roaster collects enough volume to justify proper recycling or composting. This works especially well for local roasters with regular customers.

Common Questions About Eco-Friendly Coffee Bags

1. Can all matte laminate bags be recycled?

No. Only bags made with compatible mono-materials can be recycled. Traditional multi-layer bags with mixed plastics, aluminum, or incompatible adhesives cannot be recycled, even if labeled as "recyclable."

2. Are compostable bags always better than recyclable ones?

Not necessarily. Compostable bags only work if you have industrial composting facilities13 nearby. They also provide shorter shelf life. Recyclable mono-material bags often make more practical sense.

3. How much more do sustainable bags cost?

Expect to pay 15-30% more for truly sustainable options. But costs decrease with volume. Order quantities above 10,000 units typically see better pricing.

4. Do sustainable bags protect coffee quality as well as traditional bags?

Yes, when properly designed. Modern PE/EVOH structures provide excellent barriers. Some sustainable options even outperform traditional multi-layer bags.

Conclusion

Custom matte laminate coffee bags14 can be genuinely eco-friendly, but only with careful material selection and proper disposal. Focus on mono-material structures, verify local recycling capabilities, and educate your customers. Real sustainability beats green marketing every time.

-

Discover various sustainable packaging solutions that can help reduce environmental impact. ↩

-

Understand the advantages of using PLA-lined paper for eco-friendly packaging. ↩

-

Find out how recyclable zippers contribute to sustainable packaging. ↩

-

Discover the key elements that make packaging truly sustainable. ↩

-

Explore the significance of material compatibility in the recycling process. ↩

-

Get insights into the recycling challenges faced by flexible plastics. ↩

-

Understand the importance of moisture barriers in preserving product quality. ↩

-

Learn about the benefits of using mono-materials for better recyclability. ↩

-

Understand the importance of recycling test data for sustainable packaging choices. ↩

-

Explore the advantages of using PE/EVOH structures for eco-friendly packaging. ↩

-

Find effective strategies for educating customers on proper disposal methods. ↩

-

Learn how take-back programs can enhance sustainability efforts. ↩

-

Explore the role of industrial composting in managing compostable materials. ↩

-

Explore the manufacturing process of these bags to understand their eco-friendly potential. ↩