After 8 years in sustainable packaging, I’ve learned that seal failure kills more products than any material defect. Most manufacturers focus on barrier films but ignore the sealing process until products leak.

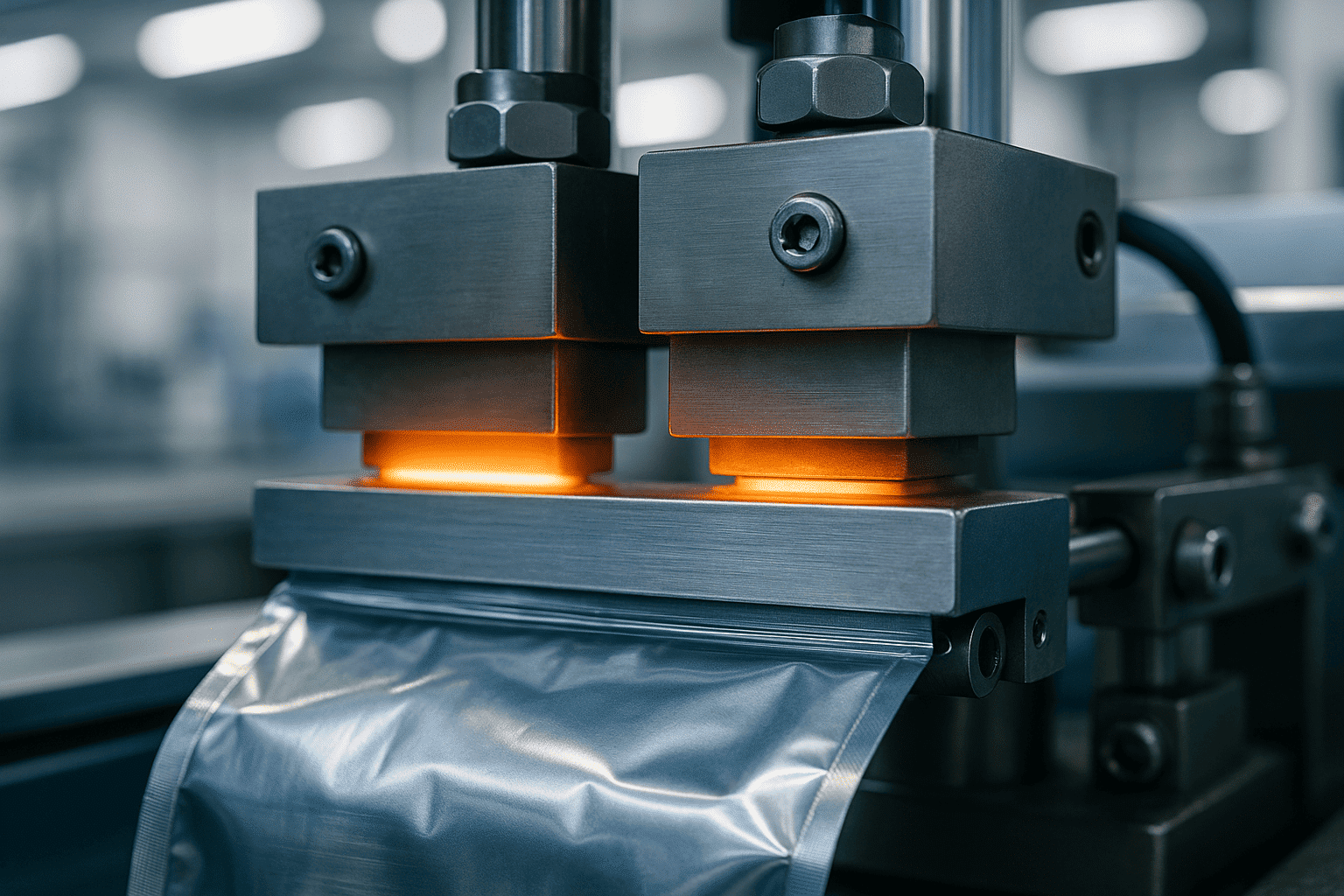

Barrier pouches are sealed using heat sealing methods1 that apply controlled temperature (typically 250-400°F), pressure (40-80 PSI), and dwell time2 (0.5-3 seconds) to create molecular bonds between seal layers. The process requires precise parameter control, contamination prevention, and continuous quality monitoring to ensure seal integrity3.

The difference between a perfect seal and a failed shipment often comes down to understanding how temperature, pressure, and time work together. Let me show you what really matters in barrier pouch sealing.

What Are the Main Heat Sealing Methods for Barrier Pouches?

When I started in packaging, I thought all heat sealers worked the same way. Then I watched a client lose $2,000 worth of product because they chose the wrong sealing method.

The two primary heat sealing methods1 for barrier pouches are impulse sealing and continuous band sealing4. Impulse sealers heat only during the sealing cycle, making them ideal for polyethylene and polypropylene materials. Band sealers maintain constant temperature and work better for high-volume production with consistent seal quality.

Impulse Sealing: The Flexible Choice

Impulse sealers only generate heat when you activate them. The sealing bar heats up instantly, creates the seal, then cools down. This method works best for materials that need lower sealing temperatures like PE and PP films.

I recommend impulse sealing5 when you’re dealing with multiple SKUs and frequent changeovers. The quick heat-up and cool-down cycles mean you can adjust parameters fast. You also save energy since the machine only uses power during the actual sealing process.

The downside? Manual operation can lead to inconsistent seals if operators don’t maintain proper dwell time2. I’ve seen facilities where seal strength varied by 30% between operators on the same machine.

Continuous Band Sealing: The Production Workhorse

Band sealers keep the sealing bars at constant temperature throughout production. The pouches move through on a conveyor belt, receiving consistent heat, pressure, and dwell time. This creates uniform seals across thousands of pouches.

For high-volume barrier pouch production, band sealing delivers the consistency you need. Every pouch gets the same treatment. The wider seal bands also provide better protection against contamination and handling stress.

How Do Temperature and Dwell Time Affect Seal Quality?

Most operators think higher temperature means stronger seals. This misconception destroys more barrier pouches6 than any other mistake I’ve encountered.

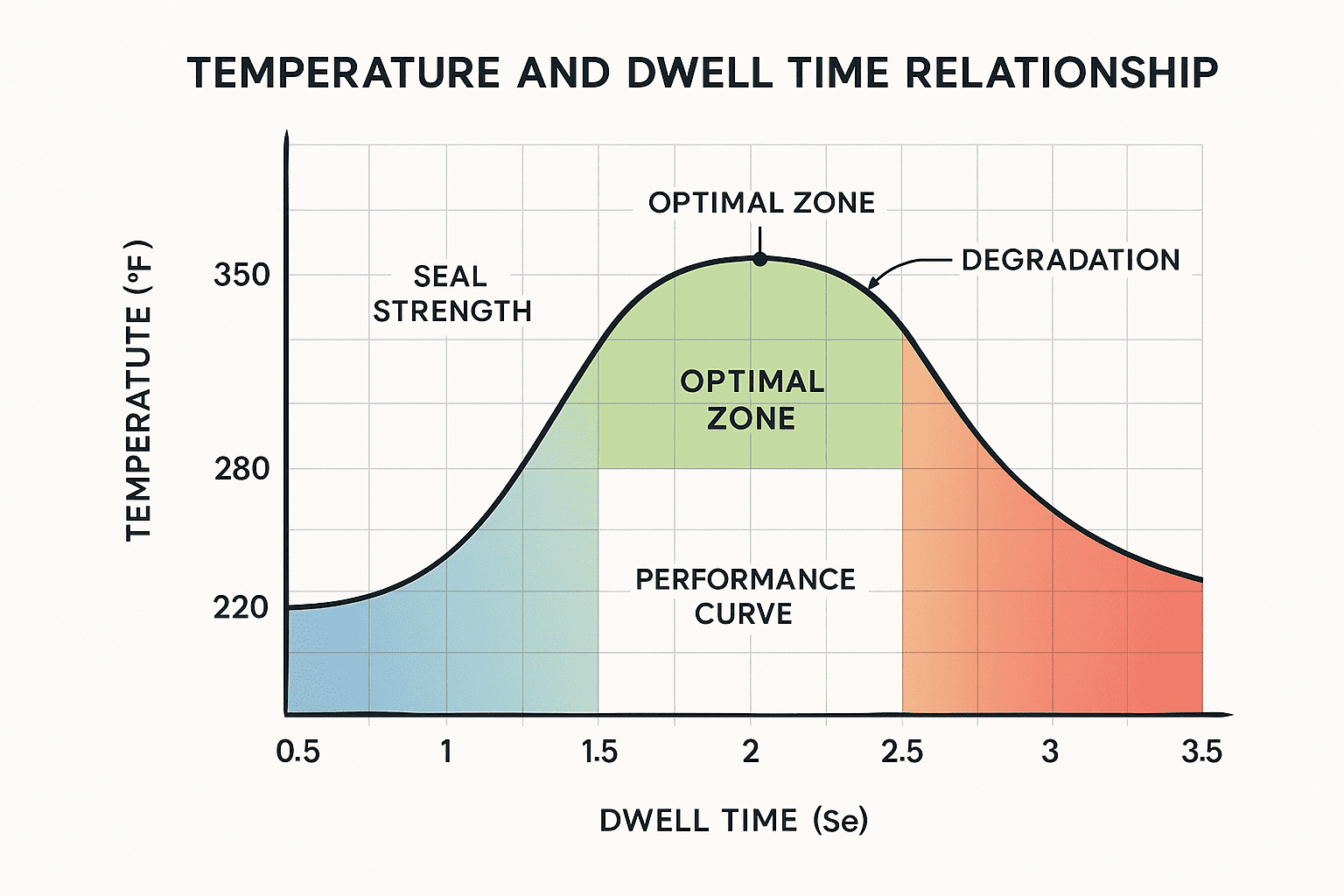

Optimal seal quality7 requires balancing temperature and dwell time based on material structure. Multi-layer barrier films typically need temperatures between 280-350°F with 1-2 second dwell times. Too much heat causes film degradation and seal thinning, while insufficient heat creates weak molecular bonds that fail under stress.

Finding Your Temperature Sweet Spot

Every barrier material has an optimal sealing temperature range. EVOH barriers seal differently than AlOx coatings. Metallized films need different parameters than clear barriers. I maintain detailed temperature profiles for each material structure we process.

Start with the film manufacturer’s recommendations, then adjust based on your specific conditions. Ambient humidity affects heat transfer. Machine age impacts temperature consistency. Even the color of your film can change optimal settings.

I test seal strength every hour during production runs. When strength drops below specification, temperature is usually the first parameter I check. A 10°F deviation can reduce seal strength by 25%.

Dwell Time: The Forgotten Variable

Dwell time determines how long heat transfers through the seal layers. Too short, and the inner layers don’t reach bonding temperature. Too long, and you risk burning through the barrier layer.

For barrier pouches with multiple layers, heat must penetrate through each film to create proper molecular bonding. A typical three-layer structure needs at least 1.5 seconds for complete heat penetration. Add more layers or thicker films, and dwell time increases.

Machine speed directly impacts dwell time in band sealers. When production demands increase, operators often speed up the line without adjusting temperature. This creates weak seals that might pass initial testing but fail during distribution.

What Contamination Issues Threaten Seal Integrity?

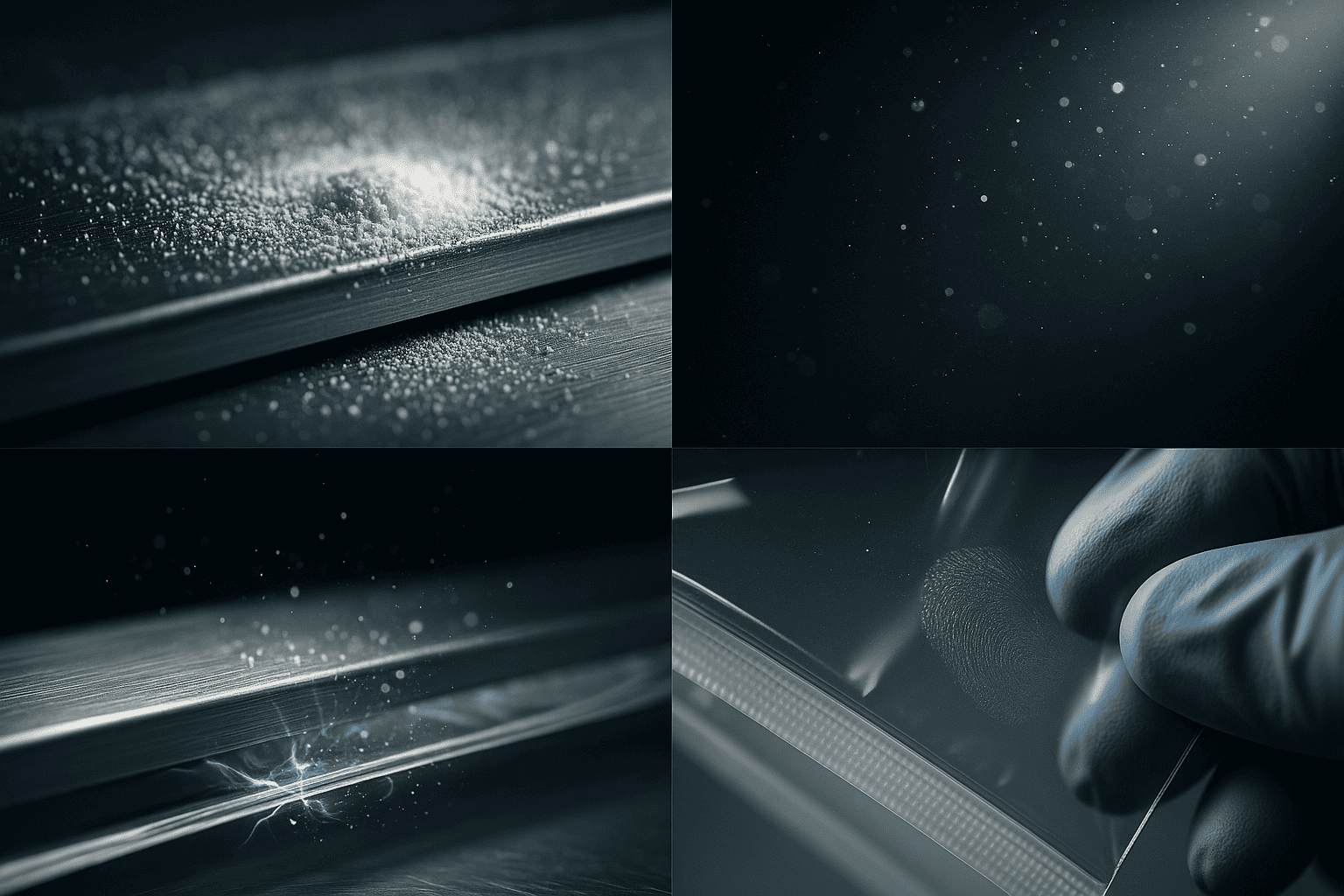

The cleanest-looking production floor can still produce seal failures. Contamination happens at microscopic levels that standard visual inspection misses.

Seal contamination occurs from product residue, dust particles, static charge8 accumulation, and operator handling. Even particles as small as 0.5 microns can create micro-channels that compromise barrier properties. Prevention requires clean room protocols, proper product settling before sealing, and static elimination systems.

Product Contamination: The Silent Seal Killer

Powder products create the worst contamination challenges. Fine particles get drawn into the seal area by static charge and air currents. I’ve seen protein powder contamination cause 15% seal failure rates even in well-managed facilities.

The solution starts before sealing. Allow products to settle after filling. Use dust collection systems near the seal area. Some operations install air knives to blow particles away just before sealing.

For liquid products, control fill levels carefully. Overfilling causes splashing that contaminates seal surfaces. I recommend keeping fill levels at least 1 inch below the seal area for liquids and 1.5 inches for powders.

Environmental and Handling Contamination

Your production environment introduces contamination you might not expect. Cardboard dust from shipping boxes, fabric fibers from uniforms, even skin cells from operators all threaten seal integrity3.

I implement strict protocols around seal areas. No cardboard boxes within 10 feet of sealing stations. Operators wear lint-free gloves and sleeves. We use tacky mats at room entrances to capture shoe contamination.

Static charge makes contamination worse by attracting particles to film surfaces. Install static elimination bars before sealing stations. Monitor humidity levels since dry air increases static buildup. During winter months, I often see seal failure rates double in facilities without humidity control.

How Can You Test and Verify Seal Quality?

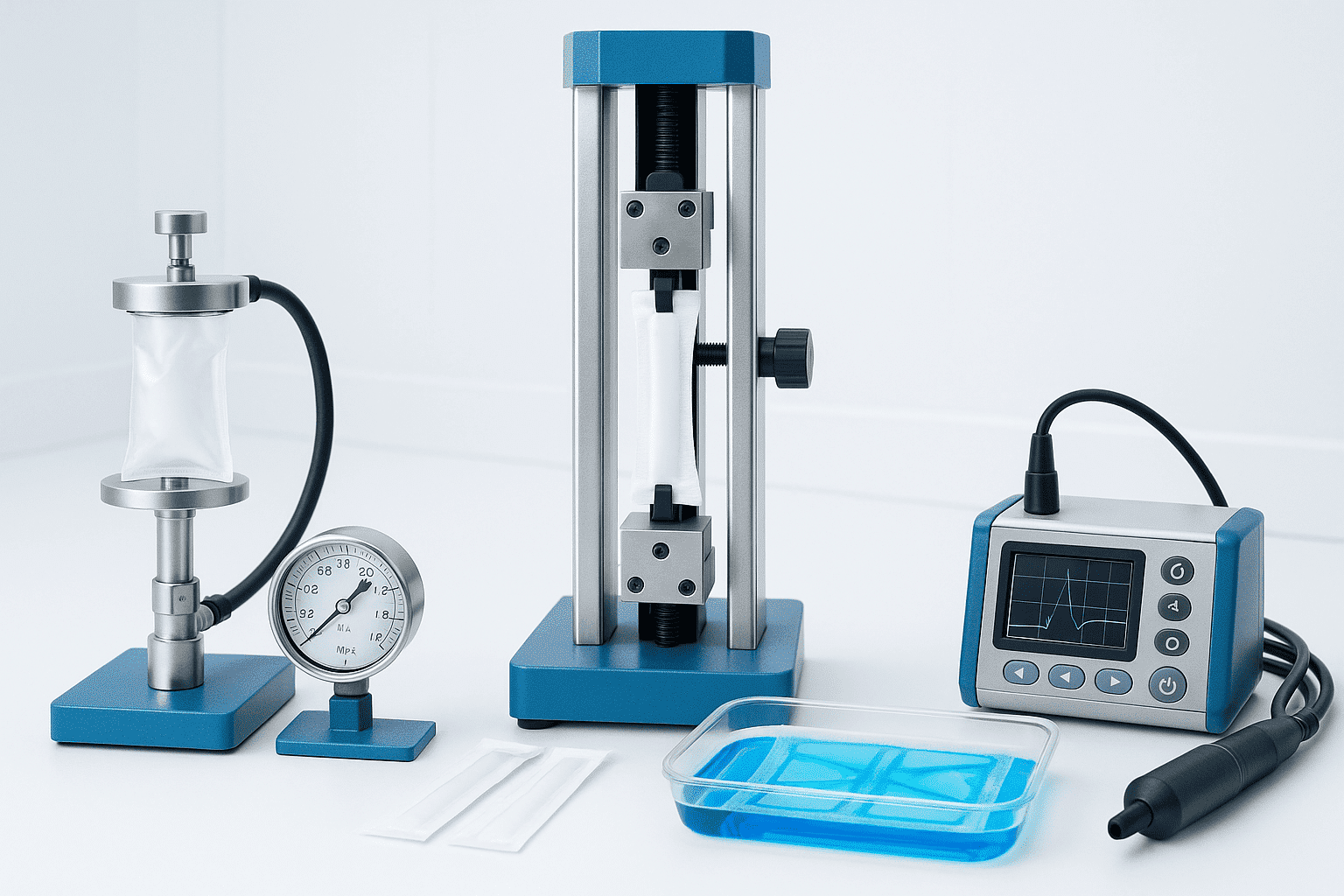

Visual inspection catches obvious defects but misses the problems that cause field failures. Real seal verification requires systematic testing protocols.

Seal quality testing includes burst testing9 (measuring maximum pressure before failure), tensile testing10 (determining peel strength), dye penetration testing11 (detecting micro-channels), and ultrasonic inspection (finding incomplete bonds). Implement both destructive sampling during production and non-destructive testing for quality assurance.

Destructive Testing Methods

Burst testing reveals overall seal strength by pressurizing pouches until failure. I test minimum 5 pouches per hour during production. Record both failure pressure and failure location. Seal failures should occur at 80% or more of film strength.

Tensile testing measures exact peel force using calibrated equipment. Cut 1-inch strips from sealed areas and pull at controlled speed. This quantifies seal strength in pounds per inch. Different products need different strength levels – pet food needs stronger seals than coffee.

Dye penetration testing finds micro-channels invisible to other methods. Inject colored dye solution into sealed pouches and check for penetration paths. This method catches contamination-related failures that pass burst tests.

Non-Destructive Testing Approaches

Ultrasonic testing detects incomplete bonds without damaging pouches. Sound waves reveal air gaps and weak spots in seal areas. I use handheld ultrasonic testers for spot checks during production.

Visual inspection still matters when done right. Train operators to recognize subtle seal defects. Wrinkles indicate temperature problems. Burn marks suggest excessive dwell time. Cloudy seals often mean contamination.

Package integrity testing uses vacuum or pressure decay to verify complete seals. Place pouches in vacuum chamber and monitor pressure changes. Leaking seals cause pressure to equalize. This method works great for 100% inspection of high-value products.

Creating Your Testing Protocol

Build testing schedules based on production risk. New products need hourly testing until parameters stabilize. Established products might need testing every 2-4 hours. Always test after equipment adjustments or shift changes.

Document everything. Record seal parameters, test results, and environmental conditions. When customer complaints arise, this data proves your due diligence. I’ve kept accounts by showing detailed seal logs when competitors couldn’t explain failures.

Common Questions About Barrier Pouch Sealing

1. How often should I calibrate sealing equipment?

I calibrate temperature control12lers monthly and verify with external thermocouples. Pressure gauges need quarterly calibration. Timer accuracy should be checked weekly since small drifts cause big quality impacts.

2. Can I seal different barrier materials with the same parameters?

No. Each barrier structure needs unique parameters. EVOH barriers seal differently than metallized films. Even changing suppliers for the same specification might require adjustment. Always validate parameters when changing materials.

3. What causes seals to fail during transportation?

Transportation stress reveals marginal seals that pass initial testing. Vibration, pressure changes, and temperature cycling all stress seals. I design seal strength with 2x safety factor for distribution challenges.

4. How do I reduce seal wrinkles in stand-up pouches?

Wrinkles usually come from uneven tension or temperature. Check film tension across the web width. Verify temperature uniformity across seal bars. Sometimes slowing line speed helps heat distribute more evenly.

Conclusion

Successful barrier pouch sealing requires mastering temperature, time, and cleanliness while maintaining rigorous testing protocols. The companies that excel treat sealing as a critical process, not an afterthought. Invest in training, maintain detailed records, and never compromise on seal integrity.

-

Learn about various heat sealing methods and their advantages for different materials. ↩ ↩

-

Explore the significance of dwell time in achieving strong seals. ↩ ↩

-

Find strategies to ensure seal integrity throughout the production process. ↩ ↩

-

Understand the advantages of continuous band sealing for high-volume production. ↩

-

Discover how impulse sealing can enhance packaging efficiency and quality. ↩

-

Explore the various applications and benefits of barrier pouches in packaging. ↩

-

Find out effective methods to maintain and verify seal quality in production. ↩

-

Explore how static charge can compromise seal quality and ways to mitigate it. ↩

-

Understand the burst testing method for evaluating seal strength and integrity. ↩

-

Learn about tensile testing and its role in measuring seal strength. ↩

-

Discover how dye penetration testing can reveal hidden seal defects. ↩

-

Learn how precise temperature control impacts seal integrity and product safety. ↩