Most coffee brands fail within two years. The shocking part? It’s rarely about the coffee quality – it’s about oxygen slowly destroying their product through poor packaging choices.

I’ve seen this scenario hundreds of times: A brand invests in beautiful packaging designs and impressive certifications, but ignores the fundamentals of barrier properties and seal integrity. Within six months, their coffee tastes stale, customers complain, and the brand disappears. The solution isn’t complex – you need to focus on three critical factors: your supplier’s film extrusion capabilities, consistent material formulations, and proven seal integrity1. These determine whether your coffee stays fresh for 12 months or deteriorates in 12 weeks.

Here’s what marketing consultants won’t tell you: The fanciest biodegradable materials mean nothing if your supplier can’t maintain consistent quality. I learned this lesson the hard way when I first started in packaging. One startup client insisted on the cheapest compostable bags for their specialty roast. Within three months, their premium Ethiopian beans were oxidizing rapidly. We switched to barrier-enhanced compostable films2s](https://mtpak.coffee/2023/11/biodegradable-coffee-packaging-benefits/)[^3], and their shelf life doubled immediately.

What Material Options Should I Consider for Coffee Packaging?

Coffee is incredibly sensitive to oxygen, moisture, and light. Choose the wrong material, and you’re essentially selling stale coffee from day one.

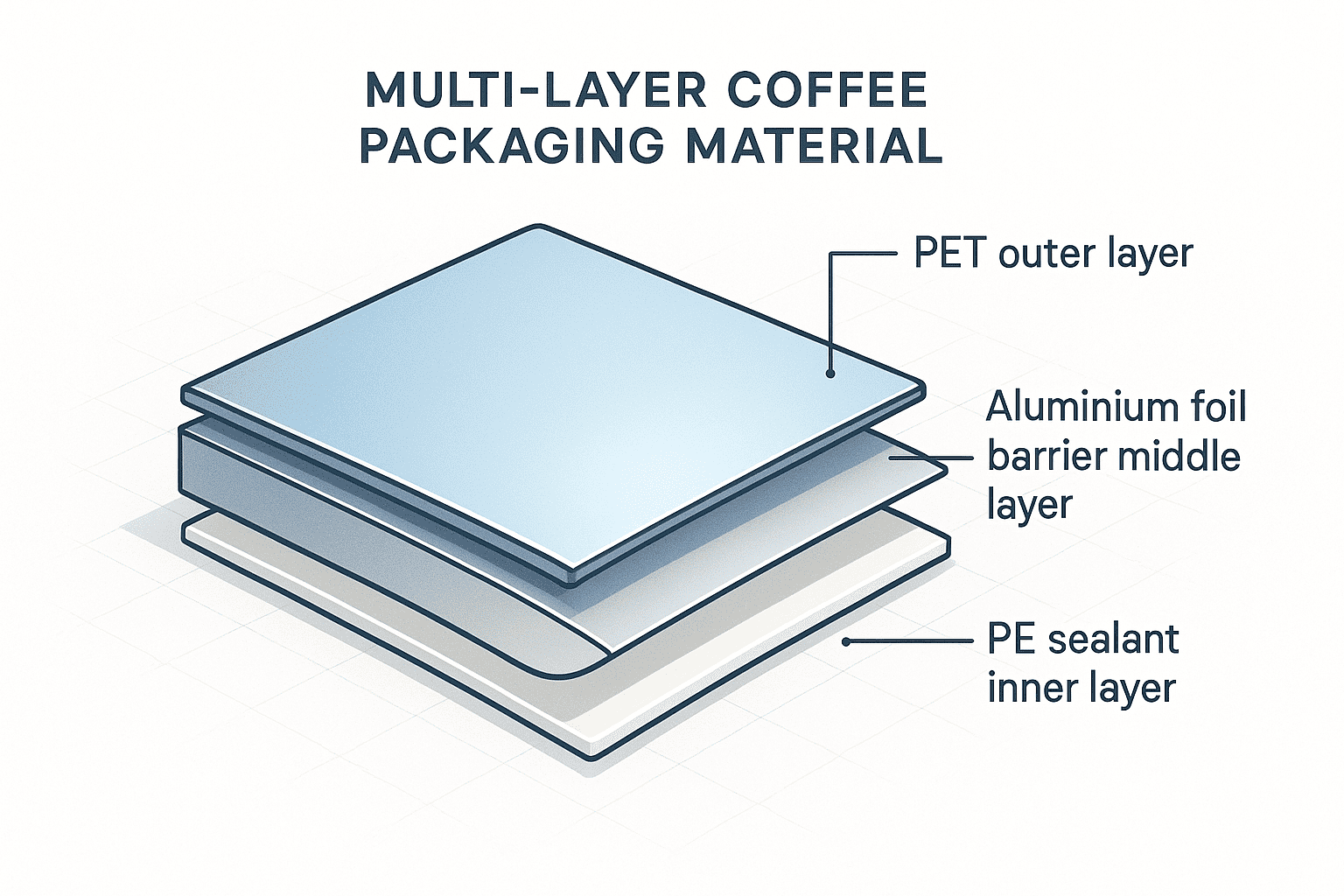

For coffee packaging, I recommend high-barrier laminated films3 as your primary choice. These multi-layer structures combine aluminum foil or metallized polyester with PE or PP sealant layers. The aluminum layer blocks 100% of light and provides an oxygen transmission rate (OTR)4 below 0.1 cc/m²/day. This combination keeps coffee fresh for 12-18 months when properly sealed.

Let me break down your main options:

Traditional High-Barrier Films

These remain the gold standard for coffee preservation. I typically suggest a three-layer structure: PET/AL/PE or PET/VMPET/PE. The PET provides strength and printability. The aluminum or metallized layer creates the barrier. The PE enables heat sealing. This structure costs about $0.15-0.25 per bag but guarantees freshness.

Sustainable Alternatives

Many brands ask me about eco-friendly options. I now offer compostable films made from cellulose and PLA. These materials provide moderate barrier properties5 – enough for specialty coffee consumed within 3-6 months. The OTR ranges from 5-20 cc/m²/day. They cost 30-40% more than traditional films but appeal to environmentally conscious consumers.

The Material Testing Protocol

Before committing to any material, I always run these tests: accelerated aging at 40°C for 30 days, seal strength testing at 15 N/15mm minimum, and drop testing from 1.5 meters. Any material that fails these tests will fail in the market.

Which Pouch Style Works Best for Different Coffee Products?

The pouch style affects everything from shelf presence to production efficiency6. Wrong choice here means higher costs and poor customer experience.

Stand-up pouches dominate the coffee market for good reasons. They maximize shelf visibility, allow for easy filling on standard equipment, and provide excellent volume-to-material ratio. I recommend flat-bottom pouches7 for premium whole beans (better stability and premium appearance) and standard stand-up pouches with zipper closures for ground coffee (cost-effective and functional).

Flat-Bottom Pouches for Premium Positioning

When clients target the specialty coffee market, I suggest flat-bottom pouches. These bags stand perfectly upright and create a premium shelf presence. The box-like shape allows for 20-30% more volume than standard stand-up pouches of similar face dimensions. Yes, they cost 15-20% more due to additional material and complex converting. But premium coffee buyers expect this packaging format.

Standard Stand-Up Pouches for Mainstream Markets

For most coffee brands, standard stand-up pouches with bottom gussets offer the best balance. They’re compatible with most filling equipment, cost-effective at $0.12-0.18 per unit, and consumers recognize the format. I always include a degassing valve8 for freshly roasted coffee – this adds $0.03-0.05 per bag but prevents package bloating and maintains freshness.

Side-Gusset Bags for Bulk Sales

Coffee shops and offices often prefer side-gusset bags9 for their 2-5 pound purchases. These bags lay flat for efficient storage and shipping. The rectangular shape makes portion control easier. I recommend these for B2B sales channels where functionality matters more than retail appeal.

How Do I Evaluate Packaging Suppliers Beyond Price?

Price negotiations are easy. Finding suppliers who won’t destroy your brand is hard. Most brands learn this too late.

The critical evaluation criteria for coffee packaging suppliers10 aren’t what most buyers examine. I focus on three factors: ownership of extrusion equipment (not just converting), minimum 5-year track record with the same formulations, and willingness to share detailed technical data. Suppliers meeting all three criteria deliver 95% fewer quality issues based on my experience with over 200 coffee brands.

The Extrusion Equipment Test

Here’s my first question to any potential supplier: "Do you own your film extrusion lines?" About 70% will say no – they buy films and only do printing and converting. These suppliers can’t control material quality when resin prices spike or formulations change. I’ve watched brands suffer when their converter’s film supplier changed formulations without notice. Oxygen barriers dropped by 50%, but nobody noticed until customers complained about stale coffee.

The Historical Sample Request

I always ask to see retained samples from three years ago. Legitimate suppliers keep samples from every production run. If those samples have yellowed, delaminated, or feel brittle, run away immediately. This aging reveals the true quality of their materials and processes. One supplier showed me perfect 5-year-old samples – they’ve been my primary partner ever since.

The Technical Transparency Test

Quality suppliers eagerly share their film recipes, test protocols, and quality data. They introduce you to their technical team, not just salespeople. They explain their quality control process in detail. Most importantly, they say "no" when you request impossible specifications. A supplier who promises everything will deliver nothing reliably.

The Crisis Response History

Ask potential suppliers about their biggest quality issue and how they handled it. Good suppliers have detailed stories about problems, root cause analysis, and corrective actions. They implemented permanent solutions, not quick fixes. This reveals their true commitment to quality and customer success.

What Closure Systems Actually Preserve Coffee Freshness?

Beautiful bags with poor closures equal stale coffee. The closure system determines whether customers enjoy fresh coffee throughout the package life.

For coffee packaging, I specify three essential closure features: a degassing valve for CO2 release without oxygen ingress, a zipper closure rated for minimum 50 open-close cycles, and heat seal strength11 of 20-25 N/15mm. This combination maintains freshness after opening while preventing catastrophic seal failures during transport.

One-Way Degassing Valves

Fresh roasted coffee releases CO2 for days after roasting. Without a valve, bags inflate or even burst. But standard valves often fail – they stick open (letting oxygen in) or clog with coffee oils. I only recommend valves with silicone oil resistance and opening pressure of 5-7 mbar. These cost $0.04-0.06 each but prevent both inflation and oxidation.

Zipper Selection and Testing

Not all zippers are equal. Coffee oils and fine particles clog cheap zippers within weeks. I specify child-resistant zippers with minimum 50-cycle durability testing. The zipper profile should include dual tracks for better seal integrity1. Press-to-close zippers work better than slider zippers for coffee – they’re less prone to coffee particle interference.

Heat Seal Optimization

The top seal often fails first. I require specific seal parameters: temperature 140-160°C, pressure 2-3 bar, dwell time 1-1.5 seconds. These settings create molecular bonding without damaging the barrier layer. I also insist on 5mm minimum seal width – narrower seals fail under transportation stress. Every batch needs seal strength testing to confirm 20-25 N/15mm force.

How Can Sustainable Packaging Maintain Coffee Quality?

Everyone wants sustainable packaging12. Few understand the quality trade-offs. I help brands navigate these challenging decisions.

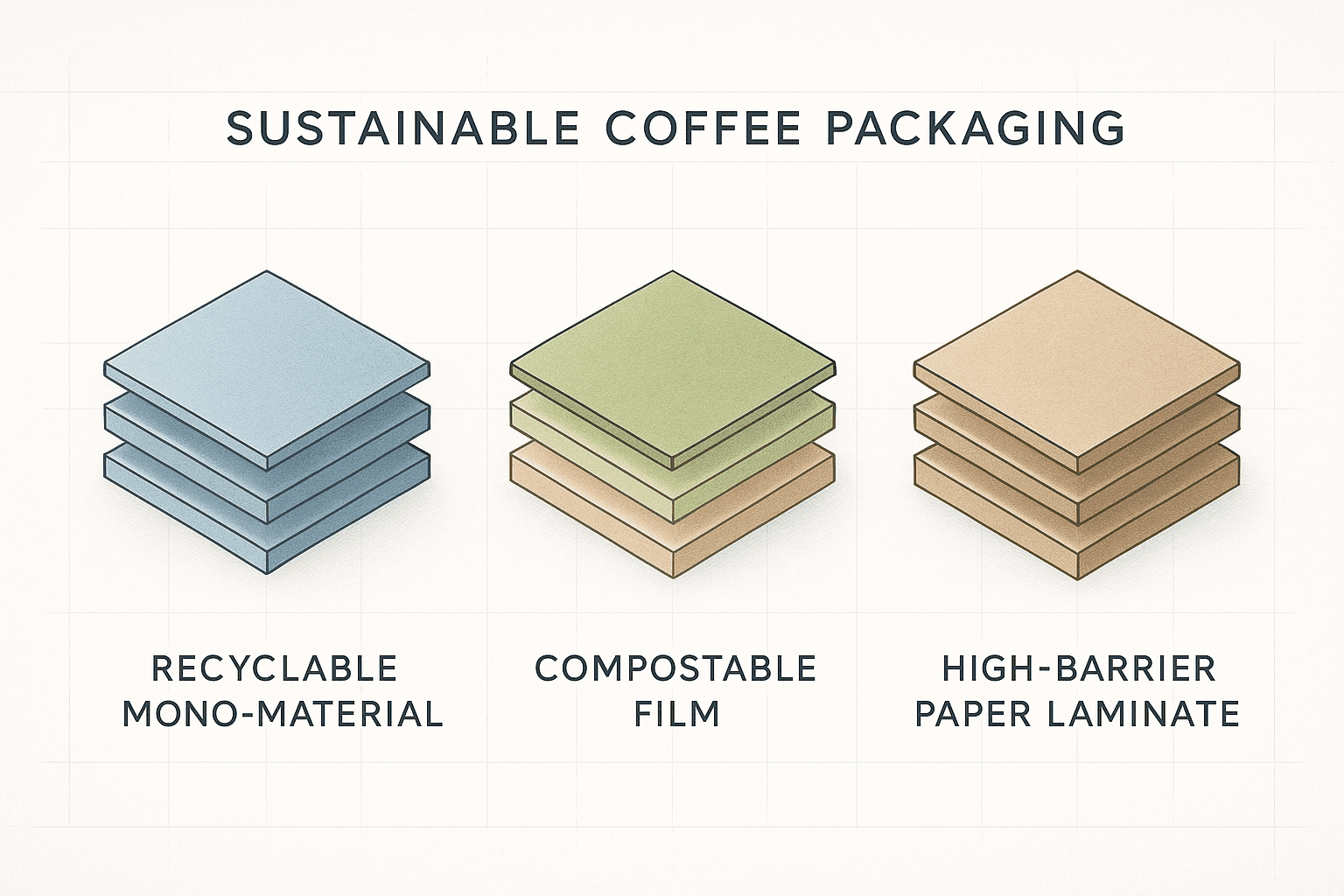

Sustainable coffee packaging requires careful material selection to balance environmental goals with product protection. I recommend mono-material structures13 like PE/PE or PP/PP for recyclability, achieving 6-month shelf life for specialty coffee. For longer shelf life14 needs, I suggest high-barrier paper laminates with water-based coatings – these provide 9-12 month protection while remaining compostable in industrial facilities.

Recyclable Mono-Material Structures

Traditional multi-material laminates can’t be recycled because separation is impossible. I now offer mono-material structures13 using only polyethylene or polypropylene layers. Special EVOH barrier layers provide oxygen protection while maintaining material compatibility. These structures achieve OTR of 0.5-2.0 cc/m²/day – adequate for specialty coffee consumed within 6 months. The entire package goes into PE or PP recycling streams.

Compostable Film Solutions

For brands prioritizing compostability, I provide PLA-based films with cellulose barriers. These materials break down in industrial composting facilities within 90 days. The barrier properties are limited – expect 3-4 month maximum shelf life. But for local roasters with quick turnover, this works perfectly. The materials cost 40-50% more than conventional films, but customers willingly pay premium prices for truly sustainable packaging.

The Sustainable Packaging Reality Check

Here’s what I tell every client: sustainable packaging12 involves trade-offs. You can achieve recyclability, compostability, or maximum barrier properties – pick two. Most brands choose recyclable mono-materials with moderate barrier properties. This satisfies environmental goals while maintaining acceptable shelf life. The key is matching packaging performance to your actual distribution timeline, not theoretical maximum shelf life.

Common Questions About Coffee Packaging Selection

1. How much should I budget for quality coffee packaging?

Quality coffee packaging typically costs $0.20-0.35 per unit for 250g-500g bags with all necessary features (barrier materials, valve, zipper). Premium sustainable options run $0.30-0.50. Remember: saving $0.05 per bag means nothing if poor packaging destroys your coffee’s reputation.

2. What’s the minimum order quantity for custom printed bags?

Most suppliers require 10,000-20,000 bags for custom printing. I suggest starting with digital printing (1,000 piece minimums) to test designs, then moving to rotogravure printing for larger volumes. This approach reduces risk while maintaining design flexibility.

3. How long does custom packaging development take?

From approved artwork to delivered bags typically takes 8-12 weeks: 2 weeks for cylinder making, 1 week for material preparation, 1 week for printing and lamination, 2-4 weeks for sea freight. Rush orders are possible but cost 30-50% more.

4. Should I choose matte or glossy finish?

Matte finishes convey premium quality and hide fingerprints but cost 10-15% more. Glossy finishes enhance color vibrancy and feel more durable. I recommend matte for specialty coffee and glossy for mainstream retail products.

Conclusion

Choosing the right coffee packaging bag determines your brand’s survival. Focus on these fundamentals: supplier capabilities over fancy features, proven barrier properties over trendy materials, and consistent quality over lowest price. The right packaging partner will tell you "no" sometimes – that’s actually a good sign.

-

Seal integrity is vital for freshness. Find out how it affects your coffee’s shelf life. ↩ ↩

-

Discover how barrier-enhanced compostable films can extend the shelf life of specialty coffee. ↩

-

Discover the benefits of high-barrier laminated films in preserving coffee quality and extending shelf life. ↩

-

Understanding OTR is crucial for maintaining coffee freshness. Explore this link to learn how it impacts your product. ↩

-

Explore the significance of barrier properties in protecting coffee from external elements. ↩

-

Learn how the right pouch style can enhance production efficiency and reduce costs. ↩

-

Discover why flat-bottom pouches are ideal for premium coffee positioning and shelf presence. ↩

-

Learn how a degassing valve can prevent stale coffee and maintain freshness after opening. ↩

-

Find out how side-gusset bags can enhance bulk sales and storage efficiency for coffee. ↩

-

Discover the key factors to consider when evaluating packaging suppliers for your coffee brand. ↩

-

Understanding heat seal strength is key to preventing package failures. Explore its significance. ↩

-

Explore sustainable packaging solutions that balance environmental goals with product protection. ↩ ↩

-

Learn about mono-material structures and their recyclability benefits for sustainable coffee packaging. ↩ ↩

-

Learn how different packaging choices can significantly impact the shelf life of your coffee. ↩