Every week, I get calls from brands asking if they should switch to stand-up pouches. They’ve heard the success stories. They’ve seen competitors making the move. But here’s what most packaging suppliers won’t tell you: the answer isn’t about the pouch itself.

The real question is whether your business understands the psychology behind modern retail. Stand-up pouches work when three conditions align: your customers value convenience over tradition1, your retailers need space efficiency, and you have 18-24 months to educate your market. If you’re looking for a quick packaging upgrade, stop here. But if you’re ready to transform how consumers interact with your brand, stand-up pouches can increase your shelf conversion rates2 by 23% while cutting packaging costs by 40%.

Most companies fail with stand-up pouches because they focus on the wrong metrics. They calculate barrier properties and filling speeds. They compare material costs. They miss the bigger picture: packaging is now a psychological trigger that happens in three seconds of shelf scanning.

What Makes Stand-Up Pouches Different from Traditional Packaging?

I’ve spent 15 years watching brands struggle with this question. The confusion happens because people compare features instead of understanding fundamental differences in consumer behavior3.

Stand-up pouches aren’t just flexible bags with a bottom gusset. They represent a shift from passive storage to active lifestyle accessories. Traditional packaging like glass jars and metal cans say "pantry staple." Stand-up pouches say "grab and go." This psychological difference drives a 40% higher pick-up rate in stores and creates new usage occasions that rigid packaging can’t access.

The structural differences go deeper than appearance. Stand-up pouches use 85% less material than rigid containers. They weigh 90% less than glass jars. But here’s what matters more: they change how products move through the supply chain.

The Supply Chain Revolution

Traditional packaging follows a linear path: manufacture empty containers, ship them to filling facilities, fill them, then ship to retailers. Each step adds cost and complexity. Stand-up pouches arrive as flat rolls. They form, fill, and seal in one operation. This eliminates entire warehouses of empty containers.

I worked with a sauce manufacturer who switched from glass jars to stand-up pouches. Their transportation costs dropped 60%. Not because pouches are lighter – though they are. The real savings came from fitting 5x more product per truck. They eliminated 200 truck trips per year.

Material Science vs Consumer Experience

Glass provides an absolute barrier. Metal cans last decades. Cardboard boxes stack perfectly. But modern consumers don’t buy packaging for these reasons. They buy convenience, and stand-up pouches4 deliver it through:

- Resealable zippers that actually work (unlike jar lids that get sticky)

- Tear notches placed where fingers naturally grip

- Transparent windows showing product freshness

- Spouts for controlled pouring without spills

How Do Stand-Up Pouches Impact Your Brand Perception?

Three years ago, I watched a premium coffee brand lose 30% market share after switching to stand-up pouches. Two years later, they gained 50% share. What changed? They learned that packaging perception isn’t fixed – it’s trained.

Stand-up pouches signal different values to different demographics. Millennials see sustainability and convenience. Gen X sees value and practicality. Boomers need education about quality preservation. Success requires understanding which message resonates with your core audience, then consistently reinforcing it for 18-24 months until new associations replace old habits.

The psychology works through three stages. First, consumers notice the different shape. This triggers curiosity or skepticism. Second, they interact with features like zippers or spouts. This creates a tactile memory. Third, they store the pouch at home. This builds daily familiarity.

The Premium Paradox

Here’s what confuses brands: stand-up pouches cost less but can command premium prices. The key is positioning. Cheap pouches look cheap. But high-quality pouches with matte finishes, soft-touch coatings, and metallic accents signal luxury.

I recommend testing perception through A/B trials5. Same product, different packaging. Track not just sales but pickup rates, time spent examining packages, and return customer percentages. One client discovered customers spent 40% more time reading their pouch versus their old box. That engagement translated to 25% higher repeat purchases.

Building Trust Through Transparency

Traditional packaging hides products behind opaque walls. Stand-up pouches can showcase contents through clear windows. This transparency builds trust, but only when products look appealing. Granola, nuts, and colorful snacks benefit. Powders and liquids might not.

The window placement matters too. Eye-level windows work for shelf display. But pouches often sit in pantries at different angles. I suggest corner windows that remain visible regardless of storage position.

What Are the Real Cost Implications?

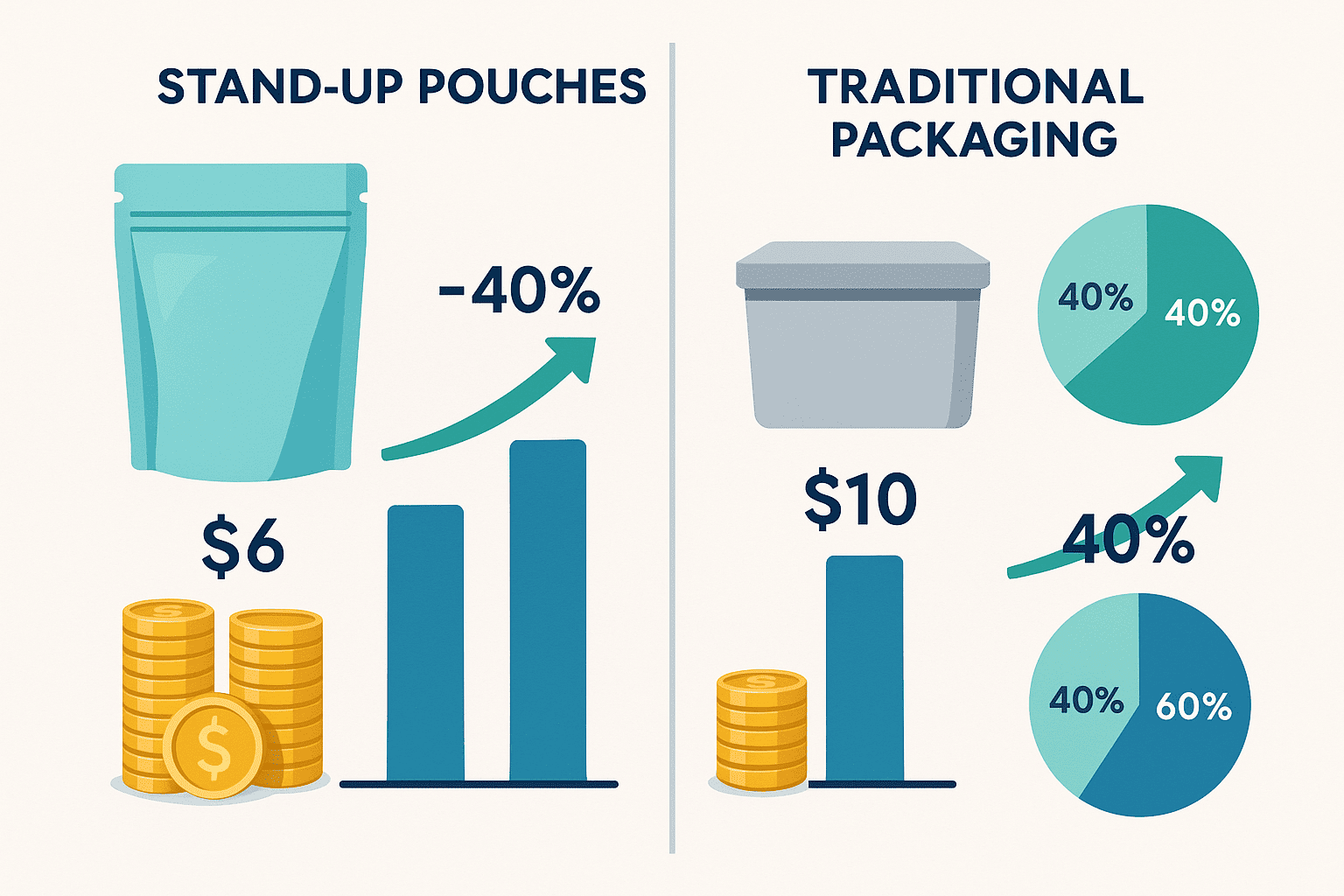

Everyone talks about material savings with stand-up pouches. Yes, you’ll save 50-70% on raw materials versus rigid packaging. But that’s not where profitability comes from.

The real financial impact of stand-up pouches comes from system-wide efficiencies. You’ll reduce shipping costs by 40%, warehouse needs by 60%, and labor requirements by 30%. But you’ll also face switching costs of $50,000-200,000 for new equipment, 6-12 months of market education6, and potential sales dips during transition. Smart brands model 3-year ROI, not quarterly savings.

Let me break down actual numbers from client transitions:

Hidden Costs Nobody Mentions

Switching to stand-up pouches requires more than buying pouches. You need new filling equipment. Form-fill-seal machines cost $100,000-500,000. Manual filling works for small batches but kills efficiency at scale.

Artwork redesign runs $5,000-15,000. You can’t just transfer existing graphics. Pouches have different proportions, viewing angles, and printing requirements. Flexographic printing differs from lithographic printing used on boxes.

Quality control changes completely. Glass jars break obviously. Pouches can have micro-punctures invisible to naked eyes. You need new testing protocols, leak detectors, and staff training.

Revenue Opportunities

But here’s what makes it worthwhile: stand-up pouches open new distribution channels7. Convenience stores prefer pouches for grab-and-go sections. E-commerce loves pouches for lower shipping costs. Subscription boxes choose pouches for efficient packing.

One pet food client couldn’t access convenience stores with their cans. After switching to pouches, convenience sales added $2M annual revenue. The pouches fit perfectly in impulse-buy zones8 near registers.

The Volume Equation

Stand-up pouches make sense at specific volumes. Below 10,000 units monthly, stick with stock packaging. From 10,000-50,000 units, consider digital printing on pouches. Above 50,000 units, invest in custom printed pouches with all features.

When Should You Consider Stand-Up Pouches?

Timing determines success more than any other factor. I’ve seen perfect products fail because brands switched too early or too late.

Consider stand-up pouches when three signals align: your category shows 20%+ pouch adoption, your retailers request flexible packaging options, and your customer feedback mentions convenience frustrations. But avoid pouches if your brand identity depends on heritage packaging, your price point requires perceived luxury, or your distribution involves rough handling that could puncture flexible films.

The category adoption rate matters because consumers learn from category norms. When coffee stayed in cans, pouch pioneers struggled. Once 20% switched, consumers accepted pouches as normal. Now 60% of specialty coffee uses pouches.

Reading Retailer Signals

Retailers drive packaging changes more than brands realize. They track metrics you don’t see: pick-up-to-purchase rates, shelf-space productivity, damage rates during stocking. When retailers suggest flexible packaging9, they’re seeing data that favors pouches.

But retailer enthusiasm varies by channel. Natural food stores embraced pouches early for sustainability. Mass merchants like pouches for efficiency. Club stores prefer large pouches for value perception. Match your packaging to your primary channel’s preferences.

Customer Frustration Indicators

Listen for specific complaints about current packaging:

- "Hard to reseal"

- "Takes too much space"

- "Can’t see how much remains"

- "Difficult to pour"

- "Too heavy to carry"

These frustrations indicate readiness for pouch solutions. But absence of complaints doesn’t mean satisfaction. Sometimes customers accept inconvenience until they experience better alternatives.

The Competition Factor

Watch competitors carefully, but don’t copy blindly. If category leaders switch to pouches, you have six months to follow before looking outdated. If newcomers use pouches to differentiate, assess whether their success comes from packaging or other factors.

I helped a brand resist pouch pressure for two years. Their glass jars communicated artisanal quality worth preserving. But when sales dropped 30%, we developed a hybrid strategy: pouches for mainstream channels, jars for specialty stores. Sales recovered within six months.

Common Questions About Stand-Up Pouch Adoption

1. Will switching to pouches make my product look cheap?

Not if you invest in quality. High-barrier films with matte finishes, spot UV coating, and metallic accents can look more premium than boxes. The key is choosing materials that match your brand positioning. I recommend starting with soft-touch matte films that feel expensive.

2. How do I educate customers about the switch?

Start with side-by-side displays showing old and new packaging. Add QR codes linking to videos explaining benefits. Use social media to share behind-the-scenes content about the change. Most importantly, give customers time. Chobani spent two years preparing their market before launching pouches.

3. What if my product doesn’t work in pouches?

Not everything belongs in pouches. Carbonated beverages need rigid containers. Fragile items need protective packaging. But most products can adapt with right modifications. I’ve helped brands package everything from liquid soaps to frozen fruits in pouches.

4. How long before I see ROI?

Typically 18-36 months. First six months show increased costs from dual inventory and education. Months 7-12 bring operational savings. Months 13-18 see market acceptance. After 18 months, full benefits emerge. Plan financing accordingly.

Conclusion

Stand-up pouches aren’t just packaging – they’re a business strategy requiring careful planning, market understanding, and patience. Success comes from recognizing that modern consumers judge quality through convenience, retailers value space efficiency over everything, and market education6 takes longer than anyone expects. Make your decision based on three-year vision, not quarterly pressures.

-

Understand why convenience is a key factor in consumers’ purchasing choices today. ↩

-

Learn how improving shelf conversion rates can significantly boost your sales numbers. ↩

-

Delve into current trends that are reshaping how consumers interact with products. ↩

-

Discover how stand-up pouches can revolutionize your brand’s packaging efficiency and appeal. ↩

-

See how testing different packaging can reveal what resonates best with consumers. ↩

-

Discover the steps to effectively educate your market about new packaging solutions. ↩ ↩

-

Discover how to identify and utilize the most effective channels for your products. ↩

-

Learn strategies to design packaging that catches the eye and drives impulsive purchases. ↩

-

Stay updated on the latest trends that could enhance your flexible packaging strategy. ↩