Small business owners face a tough choice. They want to protect the environment but worry about costs eating into their profits.

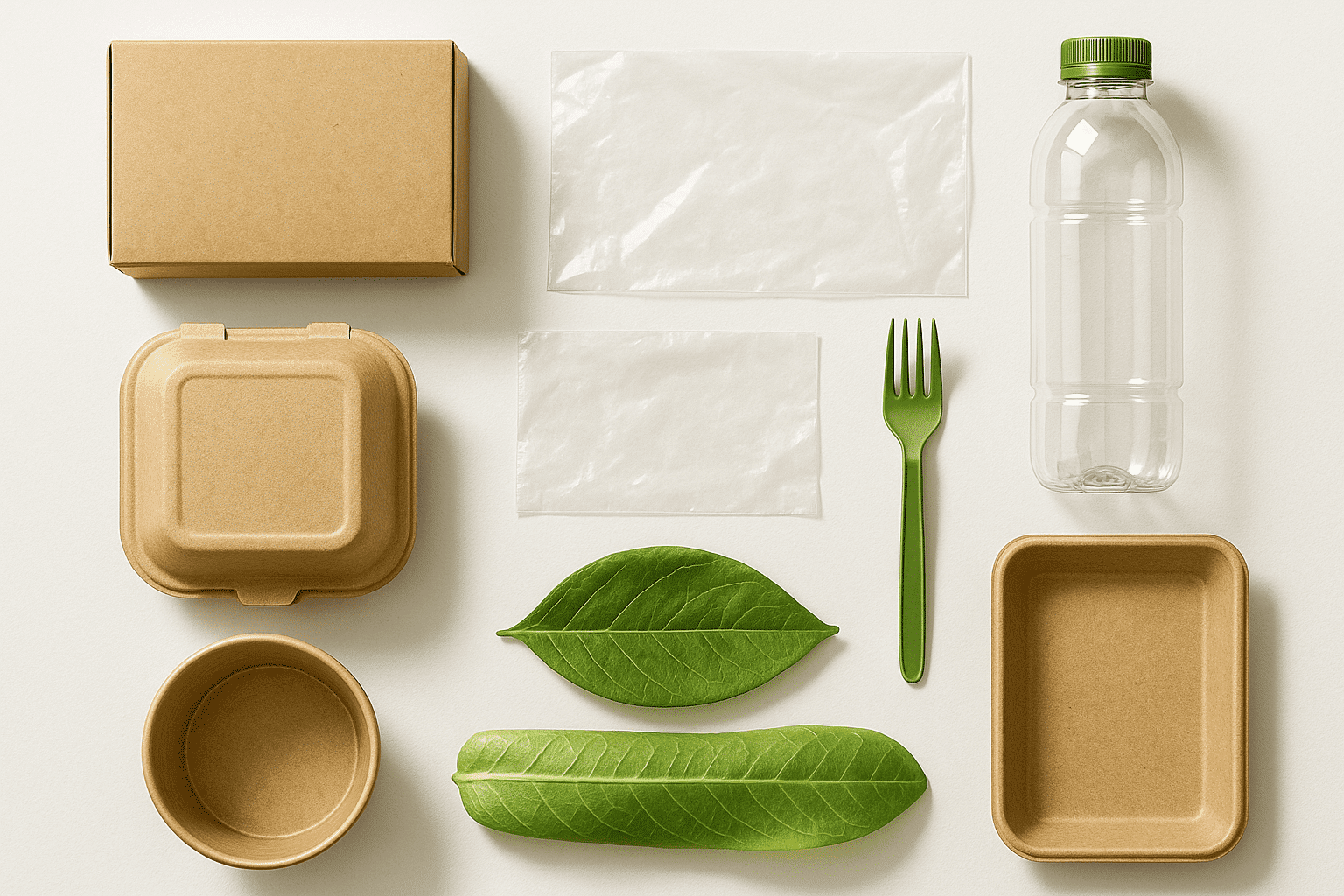

The best sustainable food packaging materials include compostable films (PLA-coated paper), recyclable mono-materials (PE or PP), plant-based bioplastics, and kraft paper laminates. These options reduce environmental impact while maintaining food safety standards. Smart material selection can actually lower total packaging costs within 18 months through reduced weight and improved logistics efficiency.

The packaging industry has spread a big lie. They claim sustainable equals expensive. I’ve worked with hundreds of small food businesses over the past decade. The truth is different. Material costs represent only 15-20% of total packaging expenses. The real savings come from lighter, more efficient materials that cut shipping costs.

Why Do Most Small Businesses Struggle with Sustainable Food Packaging?

Small food brands want to go green. They face roadblocks that big companies don’t.

The biggest barrier isn’t price but minimum order quantities. Most sustainable suppliers require 50,000+ unit minimums that small businesses can’t meet. Smart operators bypass this through buying cooperatives or packaging brokers who aggregate smaller orders, making premium sustainable materials accessible at lower volumes.

I’ve seen this pattern hundreds of times. A small organic snack company contacts me. They want compostable pouches for their granola. Traditional suppliers quote 100,000 piece minimums. That’s six months of inventory for a startup. They can’t tie up that much cash.

The solution isn’t giving up on sustainability. It’s finding the right partners. PackagingBest team specializes in this problem. We offer flexible printing options—digital printing for smaller quantities or gravure printing for larger volumes—ensuring every brand can access the best sustainable packaging materials at reasonable minimum order quantities.

The Hidden Infrastructure Problem

Here’s what most brands don’t know. Many "biodegradable" materials only break down in industrial composting facilities. These facilities don’t exist in 80% of markets. This makes biodegradable plastics functionally identical to conventional plastics for end consumers.

I always ask my clients about their local waste infrastructure. If their customers don’t have access to industrial composting, I steer them toward truly home-compostable options or recyclable materials instead.

Building Long-term Supplier Relationships

The companies that thrive long-term aren’t chasing the latest bio-material trends. They build relationships with 3-4 reliable suppliers who can scale with them. They negotiate volume commitments 12-18 months ahead. This secures better pricing and guaranteed supply during material shortages that hit this volatile market every 2-3 years.

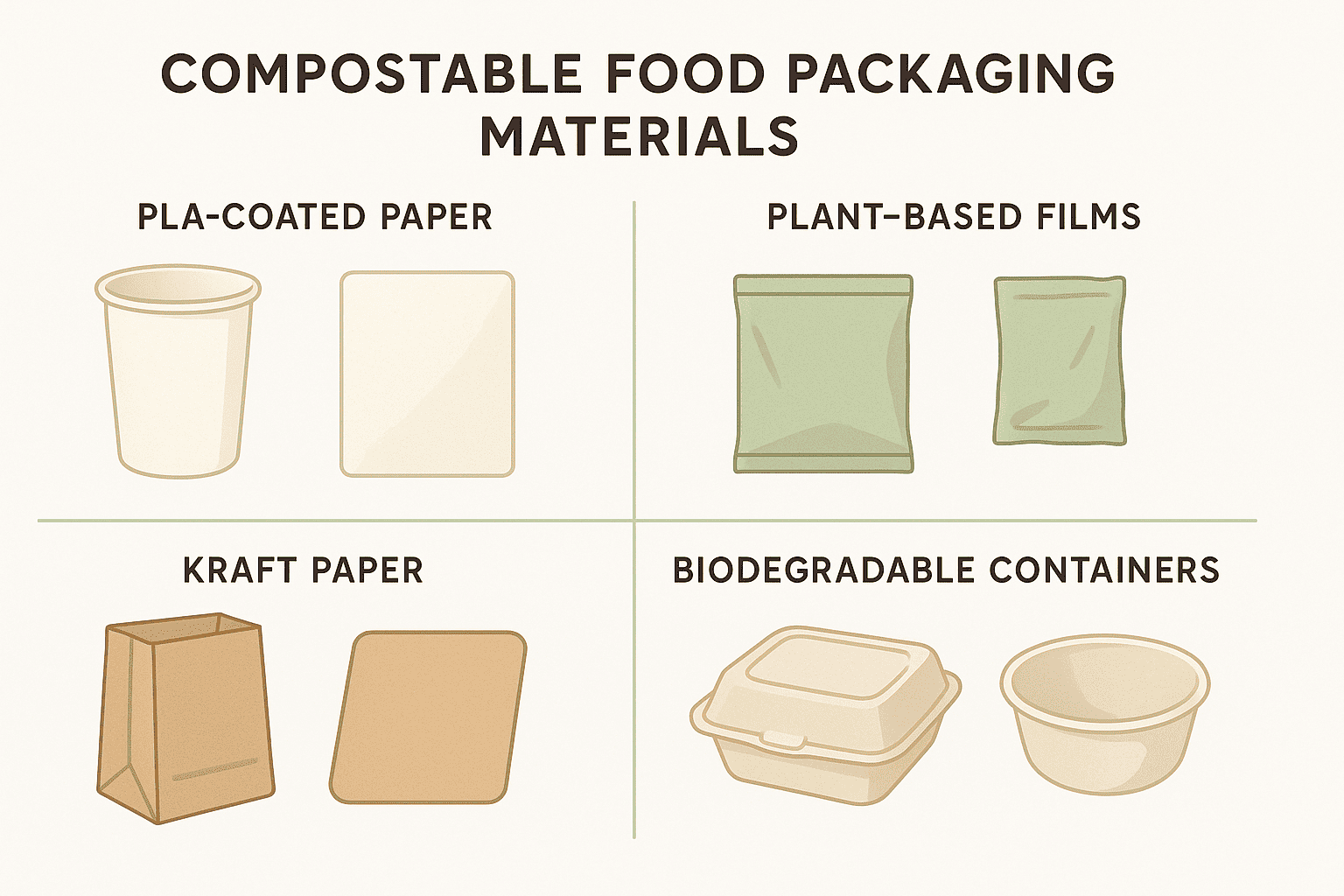

Which Compostable Materials Work Best for Food Packaging?

Compostable materials sound perfect. The reality is more complex than most brands realize.

PLA-coated paper and certified compostable films offer the best performance for food packaging. However, they require industrial composting facilities to break down properly. For true home composting, uncoated kraft paper and certain plant-based films work better, though with limited barrier properties for moisture and oxygen.

Let me break down the real-world performance of different compostable options:

PLA (Polylactic Acid) Coated Materials

PLA-coated paper works well for dry snacks and baked goods. It provides a good moisture barrier. The coating prevents grease from soaking through. I recommend this for crackers, cookies, and similar products.

The catch? PLA needs industrial composting at 140°F for 90+ days. Most home compost piles don’t reach these temperatures consistently. If your customers don’t have access to industrial composting, this becomes just another plastic waste stream.

Certified Compostable Films

Several suppliers offer films certified to ASTM D6400 or EN 13432 standards. These include materials made from cornstarch, potato starch, and other plant sources. They work well for stand-up pouches and flat bags.

I’ve tested these extensively with food clients. They perform well for products with shelf lives under 12 months. For longer shelf life requirements, the barrier properties often fall short.

Plant-Based Barrier Films

Newer materials use seaweed extracts, mushroom-based coatings, and other bio-based barriers. These show promise but remain expensive and limited in availability. Most require high minimum orders that price out small businesses.

The Reality Check

Before recommending any compostable material, I verify the local composting infrastructure. I ask clients to research their primary markets. Can their customers actually compost the packaging? If not, we look at recyclable alternatives instead.

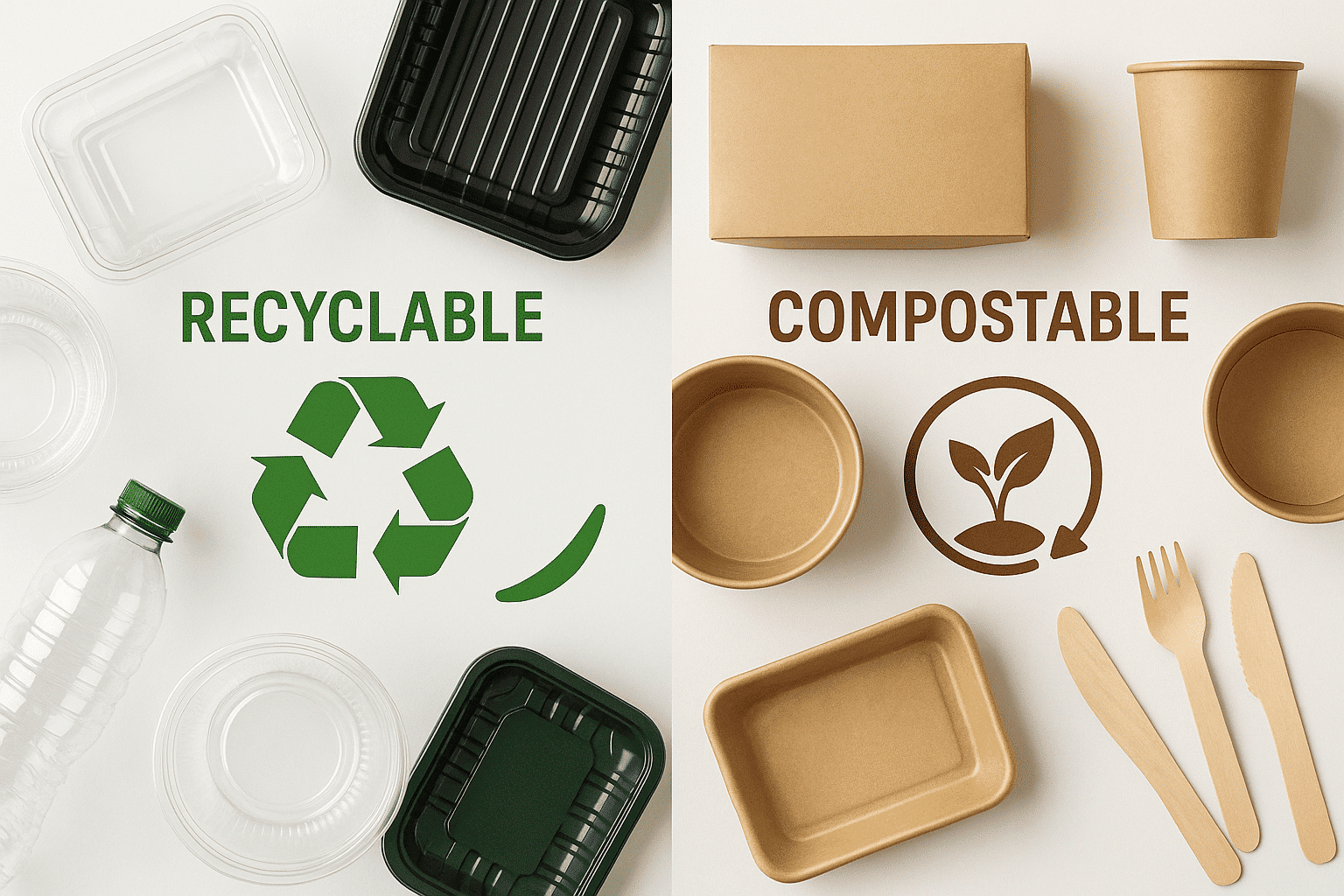

What Makes Recyclable Materials the Smart Choice for Small Businesses?

Recyclable materials offer the most practical path to sustainability for most small food businesses.

Mono-material structures using single polymer types (PE or PP) achieve recycling rates above 80% in most developed markets. These materials cost 20-30% less than compostable alternatives while providing superior barrier properties and longer shelf life capabilities.

The recycling infrastructure already exists. Unlike composting, which requires specialized facilities, plastic recycling operates in most cities. This makes recyclable packaging immediately actionable for consumers.

Mono-Material Structures

The key to recyclability is using single materials. Traditional flexible packaging combines multiple polymers and metals. This makes recycling impossible. Modern mono-material films use different grades of the same polymer for each layer.

For stand-up pouches, I often recommend all-PE structures. The outer layer uses standard PE for printability. The middle layer uses high-barrier PE for product protection. The inner layer uses food-grade PE for contact safety. All three layers recycle together seamlessly.

Design for Recyclability

Small changes in design dramatically improve recyclability. I work with clients to eliminate mixed materials. We replace metal zippers with plastic ones. We use water-based inks instead of solvent-based. We avoid metallic films that contaminate recycling streams.

These changes often reduce costs too. Simplified structures use fewer processing steps. They require less complex machinery. The savings offset any material premium.

Post-Consumer Recycled Content

Including recycled content in new packaging creates a circular loop. I recommend starting with 30% PCR content for non-food contact layers. This maintains performance while supporting recycled material markets.

The challenge is color limitations. PCR materials often have gray or brown tints. Creative design can work with these constraints. Some brands embrace the "recycled look" as part of their sustainability story.

How Do Plant-Based Packaging Materials Compare to Traditional Options?

Plant-based materials represent the fastest-growing segment in sustainable packaging.

Plant-based films from agricultural waste like rice husks, wheat straw, and sugarcane bagasse offer 40-60% lower carbon footprints than petroleum-based alternatives. They work best for dry goods packaging with shelf lives under 18 months, though barrier performance continues improving.

I’ve worked extensively with plant-based materials over the past five years. The technology has improved dramatically. Early versions had inconsistent quality and poor barrier properties. Modern plant-based films rival traditional plastics for many applications.

Agricultural Waste Sources

Rice husk films work exceptionally well for cereal and snack packaging. The natural silica content provides good moisture resistance. Wheat straw films offer excellent printability and heat seal strength. Sugarcane bagasse creates strong, puncture-resistant materials.

These waste-stream materials solve two problems. They reduce agricultural waste going to landfills. They create packaging materials with lower carbon footprints than virgin plastics.

Performance Characteristics

Plant-based materials excel in certain applications. They often have better dead-fold properties than petroleum plastics. This means they stay folded when creased, improving package appearance. They also tend to have lower static buildup, reducing dust attraction.

The limitations center on barrier properties. Most plant-based films allow more moisture and oxygen transmission than synthetic alternatives. This limits their use for products requiring extended shelf life.

Cost Considerations

Plant-based materials typically cost 15-25% more than conventional plastics at current volumes. However, this gap narrows as production scales up. Some clients find the premium worthwhile for brand positioning and customer appeal.

I advise clients to test plant-based options for specific products rather than switching everything at once. Start with products that don’t require high barriers. Learn what works before expanding usage.

What Are the Best Sustainable Packaging Solutions for Different Food Categories?

Different food types need different sustainable approaches. What works for dry snacks fails for fresh produce.

Dry goods perform best with kraft paper laminates or plant-based films. Fresh products need breathable materials like perforated bio-films. Liquid products require multi-layer barrier structures using recyclable mono-materials. Frozen foods need specialized low-temperature compostable films.

I’ve developed specific recommendations for each major food category based on performance testing and client feedback:

Dry Snacks and Baked Goods

For products like chips, crackers, and cookies, I recommend kraft paper with bio-based barrier coatings. This provides excellent grease resistance and printability. The paper substrate appeals to environmentally conscious consumers. It’s also cost-effective for small runs.

Stand-up pouches work well for granola, nuts, and trail mixes. I suggest compostable films for premium brands in markets with good composting infrastructure. For other markets, recyclable PE structures perform better.

Fresh Produce and Prepared Foods

Fresh products need to breathe. Traditional plastic films trap moisture and accelerate spoilage. I recommend perforated bio-films that allow controlled gas exchange. These extend shelf life while remaining compostable.

For prepared salads and cut vegetables, modified atmosphere packaging using compostable films shows good results. The key is matching the perforation pattern to the specific product’s respiration rate.

Liquid Products and Sauces

Liquids present the biggest challenge for sustainable packaging. They need excellent barrier properties and seal strength. I typically recommend recyclable structures for these applications.

Multi-layer films using different grades of PE or PP provide the necessary performance. The inner layer contacts the food safely. The middle layer provides barrier properties. The outer layer accepts printing and maintains package integrity.

Frozen Foods

Frozen applications require materials that remain flexible at low temperatures. Many bio-based films become brittle when frozen. I recommend specialized low-temperature compostable films for premium frozen products.

For mainstream frozen foods, recyclable PE structures perform best. They maintain flexibility and seal integrity throughout the cold chain.

How Can Small Food Businesses Implement Sustainable Packaging Strategies?

Implementation requires a systematic approach. Changing everything at once often fails.

Start with one product line using proven sustainable materials. Test market acceptance and supply chain performance for 6 months. Scale successful solutions to other products while building supplier relationships for better pricing and reliability.

I guide clients through a structured implementation process:

Phase 1: Assessment and Planning

First, we audit current packaging across all products. I evaluate which items offer the best opportunities for sustainable conversion. We consider factors like shelf life requirements, barrier needs, and production volumes.

We also assess the target market’s infrastructure. Do customers have access to recycling or composting facilities? This determines which sustainable options will actually deliver environmental benefits.

Phase 2: Pilot Testing

We select one product for initial conversion. I recommend starting with a product that has moderate barrier requirements and decent volume. This provides meaningful learning while limiting risk.

The pilot runs for 3-6 months. We track multiple metrics: material costs, production efficiency, customer feedback, and actual end-of-life outcomes. This data guides decisions about scaling up.

Phase 3: Supplier Development

Successful pilots reveal which suppliers can deliver quality and service. We then work to strengthen these relationships. I help clients negotiate volume commitments in exchange for better pricing and guaranteed supply.

Building redundancy is crucial. I recommend developing relationships with 2-3 suppliers for each critical material. This prevents supply disruptions that could force reverting to conventional packaging.

Phase 4: Portfolio Expansion

With proven materials and suppliers, we systematically convert the rest of the product portfolio. The order depends on customer impact, volume, and complexity. High-visibility products often convert first for marketing benefits.

Each conversion builds on previous learning. The process accelerates as teams gain experience and suppliers improve their capabilities.

Frequently Asked Questions About Sustainable Food Packaging

1. Do sustainable packaging materials really cost more than conventional options?

Material costs are typically 10-25% higher, but total packaging costs often decrease due to lighter weight, better logistics efficiency, and reduced waste disposal fees. The payback period averages 12-18 months for most businesses.

2. How do I know if my customers can actually recycle or compost the packaging?

Research your primary markets’ waste infrastructure. Contact local waste management companies about their capabilities. For recyclable materials, check if they accept flexible films. For compostable materials, verify industrial composting availability.

3. What’s the difference between biodegradable and compostable packaging?

Biodegradable means it breaks down naturally but doesn’t specify timeframe or conditions. Compostable means it breaks down into non-toxic components within specific timeframes under controlled conditions. Look for certifications like ASTM D6400 or BPI certification.

4. Can sustainable packaging provide the same shelf life as conventional packaging?

For most products, yes. Modern sustainable materials offer barrier properties comparable to conventional plastics. However, some applications with extreme shelf life requirements (2+ years) may need conventional packaging or modified product formulations.

5. How do I find suppliers willing to work with small order quantities?

Look for packaging brokers who specialize in small businesses, join buying cooperatives with other brands, or consider working with converters who can aggregate orders. Many sustainable material suppliers are also developing small-run capabilities to serve growing demand.

Conclusion

Sustainable food packaging isn’t just possible for small businesses – it’s becoming essential. The key lies in choosing materials that match your specific needs and local infrastructure. Focus on building relationships with reliable suppliers who can grow with your business. Start small, test thoroughly, and scale what works.