You think measuring cannabis is simple math, but I’ve watched businesses lose everything over 0.2 grams.

Cannabis is measured by weight1 in grams and ounces. Common measurements include: 1 gram (smallest retail unit), 3.5 grams (eighth), 7 grams (quarter), 14 grams (half), and 28 grams (ounce). Each measurement requires specific packaging considerations2 for weight preservation.

Here’s what 25 years in flexible packaging taught me: the weight on your scale isn’t the weight that matters. The weight that arrives at your customer matters more.

Why Do Cannabis Weights Change After Packaging?

I learned this lesson the hard way when a client called me panicking about weight discrepancies.

Cannabis loses 15-20% weight in the first 30 days due to moisture migration3. This happens because cannabis flower contains volatile compounds and water that evaporate through packaging materials. Standard plastic bags allow 0.5-2.0 cc/100in²/day oxygen transmission, accelerating moisture loss.

Understanding Moisture Migration Rates

I measure moisture loss in every packaging type we produce. Here’s what my testing shows:

| Packaging Type | OTR Rate (cc/100in²/day) | Weight Loss (30 days) | Legal Risk |

|---|---|---|---|

| Standard PE Bag4 | 2.0-3.0 | 18-22% | High |

| Barrier Pouch5 | 0.5-1.0 | 8-12% | Medium |

| Modified Atmosphere | 0.1-0.5 | 3-5% | Low |

| Mylar with Nitrogen6 | <0.1 | 1-3% | Minimal |

The difference between these packaging types isn’t just numbers. I’ve seen prosecutors use weight discrepancies as evidence. A client in California packaged eighths at exactly 3.5 grams. Three weeks later, police tested them at 3.1 grams. That 0.4-gram difference triggered legal action.

Smart operators now package at 3.7 grams minimum. They document weight at packaging, after 7 days, and after 30 days. This creates a legal defense showing natural weight loss, not intentional shorting.

How Should Different Cannabis Measurements Be Packaged?

Every measurement needs its own packaging strategy based on surface area to volume ratio.

Different cannabis measurements require specific packaging sizes and barrier properties. Single grams need 3"x4" pouches with basic barriers. Eighths need 4"x6" pouches with moisture control. Quarters and above need 5"x8" or larger with humidity regulation systems to maintain weight compliance.

Packaging Requirements by Weight

I’ve tested thousands of packages across every standard measurement. Here’s what works:

1 Gram Packaging

Single grams have the highest surface area to volume ratio. They lose moisture fastest. I recommend 3"x4" pouches with at least 4.5 mil thickness. Add a 62% humidity pack even for this small amount. The extra cost is $0.03 per unit, but it prevents 90% of weight-related complaints.

3.5 Grams (Eighth) Packaging

Eighths are the most common retail size. Use 4"x6" child-resistant pouches with 5 mil minimum thickness. I specify metalized polyester outer layers with LLDPE inner layers. This combination keeps OTR below 0.5 cc/100in²/day. Always include headspace for humidity packs7.

7-14 Grams (Quarter to Half) Packaging

Larger amounts need 5"x8" stand-up pouches with gusseted bottoms. I use three-layer structures: PET/AL/PE or PET/VMPET/PE. These maintain shape while preventing crushing. Add tear notches exactly 0.5" below the zipper for controlled opening.

28 Grams (Ounce) Packaging

Ounces require 6"x9" or larger pouches with reinforced seals. I triple-seal the top closure because seal integrity affects everything. Include two-way humidity control and consider nitrogen flushing for premium products.

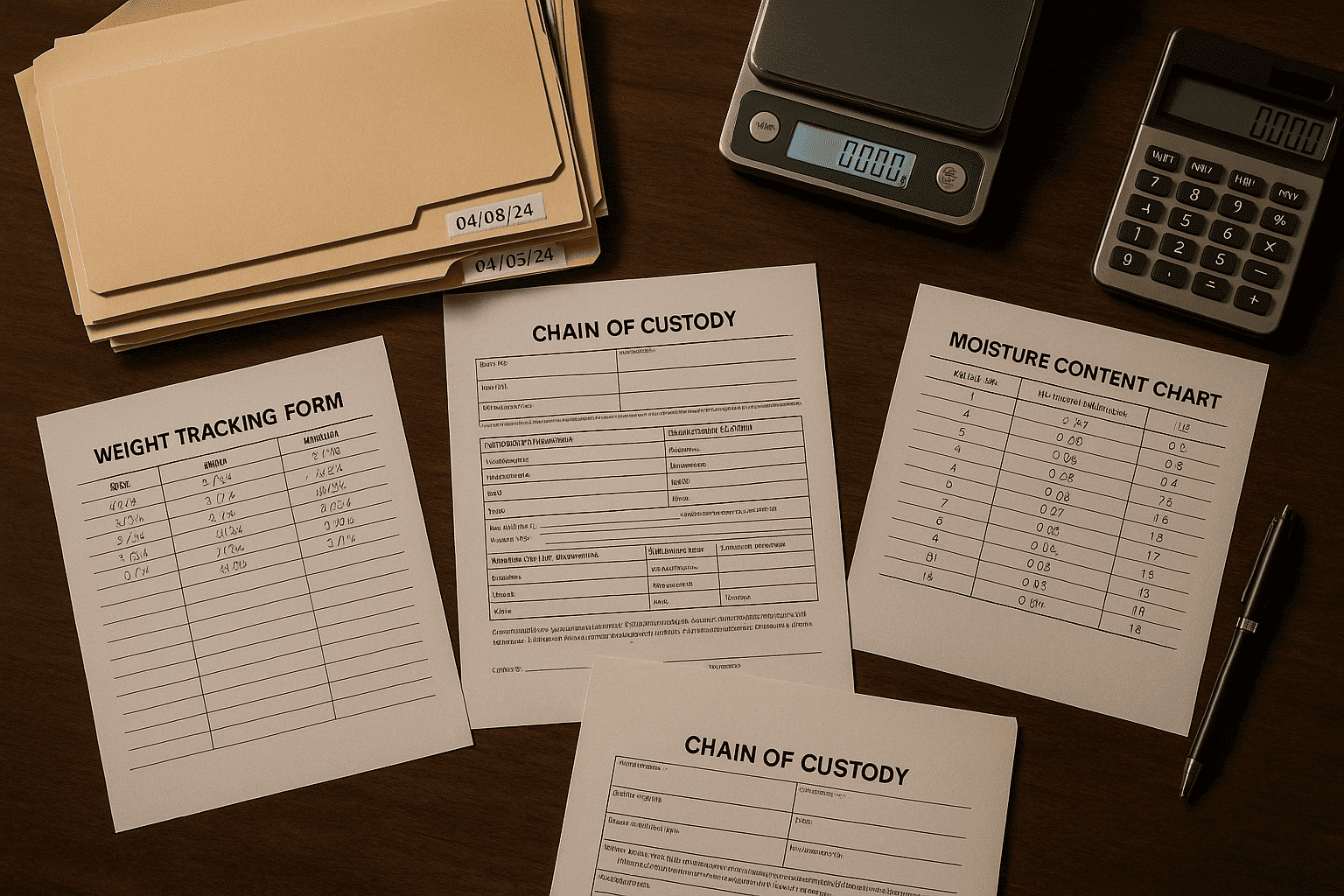

What Legal Protections Do Proper Measurements Provide?

I’ve been an expert witness in three cannabis weight cases, and documentation saved every client.

Proper weight documentation provides legal protection by establishing chain of custody8 and natural weight variance patterns. Courts recognize moisture loss when you document weights at packaging, after curing, during storage, and at point of sale. This creates reasonable doubt about intentional shorting.

Building Your Weight Defense System

After helping dozens of cannabis companies avoid prosecution, I developed this system:

Pre-Package Documentation

Weigh and photograph every batch before packaging. Use certified scales with 0.01g accuracy. Print timestamps on all photos. Store this data for five years minimum. I’ve seen cases dismissed because companies had pre-package weights proving compliance.

In-Package Monitoring

Place humidity indicators9 inside random samples. These cards change color when moisture drops below optimal levels. They cost $0.02 each but provide visual proof of storage conditions. Prosecutors can’t argue with photographic evidence of proper storage.

Post-Package Tracking

Test weights weekly for the first month, then monthly after. Document everything in a blockchain-verified system10. I recommend Tracifier or MJ Freeway for compliance tracking. These platforms timestamp everything and create immutable records.

The companies surviving increased enforcement aren’t lucky. They understand weight variance happens naturally. They package over-weight, document everything, and use proper barriers. Your measurement system becomes your legal defense.

Common Questions About Cannabis Weight Measurements

1. Why does my cannabis weigh less after a few weeks?

Cannabis naturally loses moisture through evaporation. Even in sealed packages, standard plastic allows moisture to escape at rates of 0.5-2.0 grams per month depending on storage conditions and packaging quality.

2. What’s the most accurate way to package specific weights?

Package 5-10% over target weight, use humidity control packs set at 58-62%, and choose packaging with OTR rates below 0.5 cc/100in²/day. Document initial weight and expected variance on labels.

3. How do dispensaries handle weight discrepancies11?

Most dispensaries have 2-3% acceptable variance policies. They weigh products upon receipt and document any discrepancies. Products outside variance ranges get rejected or trigger supplier audits.

Conclusion

Cannabis measurements aren’t just numbers on scales. They’re your compliance foundation, your legal protection, and your business survival strategy in this regulated industry.

-

Understanding cannabis weight measurement is crucial for accurate sales and compliance. ↩

-

Explore essential packaging strategies that preserve cannabis weight and integrity. ↩

-

Learn about moisture migration to understand its impact on cannabis weight and quality. ↩

-

Get insights into Standard PE Bags used in cannabis packaging and their limitations. ↩

-

Learn how Barrier Pouches can reduce moisture loss in cannabis storage. ↩

-

Find out why Mylar with Nitrogen is an effective solution for cannabis packaging. ↩

-

Discover how humidity packs can help maintain cannabis weight and quality. ↩

-

Understand the significance of maintaining a chain of custody for compliance. ↩

-

Find out how humidity indicators ensure quality and compliance for cannabis products. ↩

-

Explore how blockchain technology improves transparency and compliance in cannabis. ↩

-

Identifying weight discrepancies can help businesses avoid legal issues. ↩