custom spout pouches for liquid & semi-liquid products

Get custom spout pouches engineered for your line—low MOQs, 15–22-day production, mono-PE/PP recyclable or compostable films, hot-/cold-fill ready, with engineer-guided fitment choices.

Is a spouted pouch right for you?

Choose stand-up or flat-bottom formats, then match corner or top-center spouts to your filling and pour needs.

Handling liquids or purées? With custom spout pouches, you balance protection, line speed, and user experience without rigid bottles. Pick stand-up for everyday sizes or flat-bottom for larger volumes, choose corner spouts for ergonomic pouring, top-center for symmetric filling. The format supports cold-fill, hot-fill, and pasteurization under mild aseptic setups when specified. Align viscosity, cap style, and torque with your co-packer to avoid leaks and foaming.

You want lower freight and shelf footprint

You need hot-fill or pasteurization compatibility

You prefer controllable, mess-free pouring angles

You run many SKUs with agile branding

Where spouted pouches fit best

Map your product to the right format—stand-up or flat-bottom—then match spout placement to how you fill and pour.

Sauces

Controlled pours, less glugging, cleaner caps.

Baby food

Easy squeeze, reclose, travel-friendly.

Detergent refills

Ergonomic pouring at larger volumes.

Liquid supplements

Dose control with leak prevention.

Choose spouted stand-up pouches when you want everyday sizes and shelf-ready presence, or flat-bottom spout pouches when you need higher volumes and stable bases. If you prefer ergonomic, mess-free pouring, corner spouts excel. If you prioritize symmetric filling, top-center fits better. Match viscosity and cap style to your line to avoid foaming and leaks. When you manage many SKUs, digital printing speeds launches, gravure lowers unit cost at scale.

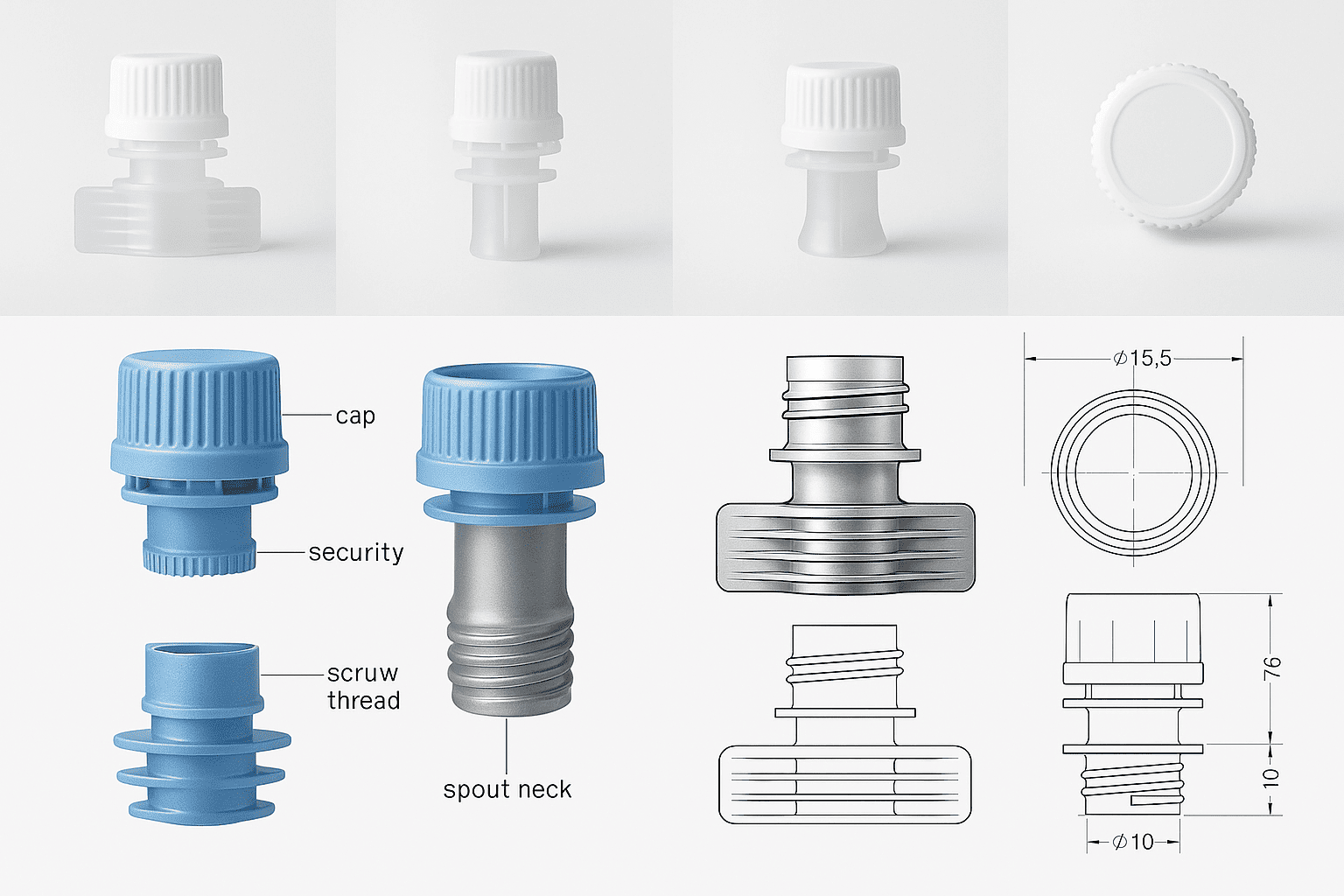

Spout & cap options

Select fitments that protect product, speed your line, and improve pouring—without locking you into fixed diameters.

- Tamper-evident ring caps by default.

- Flip-top caps enable one-hand dosing and fast reclose.

- Long vs short caps balance grip, height, and shipping.

- Custom colors available, accessory MOQs are higher.

- Corner vs top-center influences pouring and sealing.

Fitment quick guide

| Option | Best for |

|---|---|

| Corner spout | Ergonomic, mess-free pouring, larger refill packs |

| Top-center spout | Symmetric filling/capping, balanced shelf display |

| Flip-top cap | One-hand dosing, faster reopen/close |

| Tamper-evident ring | First-open integrity for retail |

| Long vs short cap | Better grip vs lower height for shipping |

Spout Pouch Materials & Barrier

Your shelf life, viscosity, and filling temperature drive film choice. Mono-PE and mono-PP keep you closer to recycle-ready designs in many regions, while compostable films support specific sustainability goals. For liquids and purées, pair barrier levels to oxygen and moisture sensitivity rather than defaulting to heavy stacks. We’ll map clarity (clear/matte), stiffness, and seal strength to your SKU, then confirm barrier targets at the quote stage. All values below are illustrative, not guarantees.

| Film stack (illustrative) | Typical uses | Clarity/finish | Barrier notes (OTR/WVTR) | Notes |

|---|---|---|---|---|

| Mono-PE (BOPE / PE-EVOH-PE) | Sauces, baby purées | Clear / matte | Moderate–High O₂, Moderate H₂O | Recycle-oriented design where accepted, seal-friendly. |

| Mono-PP (BOPP / CPP / CPP) | Oils, refill detergents | Clear / matte | Low–Moderate O₂, Low H₂O | Higher heat resistance, good stiffness for spouts. |

| Compostable options (e.g., PLA blends, kraft available) | Category-specific | Opaque / paper | Moderate O₂, Higher H₂O | Home/industrial compostability varies by region. |

Custom Spouted Pouch Printing & branding

Match your volumes and color control—go digital for agility, gravure for scale and precise Pantone/metallic results.

| Criteria | Digital printing | Gravure printing |

|---|---|---|

| MOQ | From 1,000 pcs per design | From 5,000 pcs per design |

| Colors | Unlimited, agile artwork changes | Up to 9, Pantone & metallics |

| Setup | No plates, faster to start | Plates required, prep time applies |

| Best for | Short runs, many SKUs | Scale runs, stable artwork |

Pricing, lead time, samples & dielines

Request samples and dielines here, then share a few specs—fill method & product, shelf life, quantities, and destination—so you get a fast, accurate quote.

Existing samples

Free Film swatches & prior pouches, shipping fee on you, dispatch in 1–3 business days after payment.

Custom print prototypes

Printed proof pieces, proofing fee applies, rebate depends on final order size.

Dielines

Dielines for your spec, provided on request via form.

- Tell us fill method and temperature range.

- Share product type, viscosity, and shelf life.

- Choose spout placement and cap behavior preference.

- Provide order quantity and destination country.

- Attach artwork if printing is required.

FAQs About Custom Spout Pouches

What are custom spout pouches?

They’re flexible, resealable pouches with a fitment and cap for controlled pouring—often chosen over rigid bottles for lighter weight and convenience.

Are spouted pouches recyclable or compostable?

Recycle-readiness depends on local programs; mono-PE or mono-PP structures exist, and some suppliers offer compostable laminates. Always verify regional acceptance—logos aren’t provided here.

Can they run hot-fill or pasteurization?

Yes—when films, seals, and filling windows are specified for heat. Many systems support ambient, hot-fill, and mild aseptic/pasteurization workflows.

Which products are a good fit?

Beverages, baby food, sauces, oils, liquid supplements, and home/cleaning refills commonly use spouted stand-up pouches for mess-free dispensing and portability.

What spout placements and cap styles are common?

Corner and top-center placements are typical, caps include tamper-evident rings and flip-tops. Choose diameter/style by viscosity and dispensing control.

Do spouted pouches reduce shipping weight vs bottles?

They use less material and can lower transport footprint compared with rigid packaging, while maintaining shelf presence.

What printing options are typical for branding?

Digital suits agile, multi-SKU runs; gravure supports precise Pantone/metallic control—many suppliers list up to 9–10 colors on roto/gravure lines.

Flat-bottom vs stand-up spouted pouches—how to choose?

Flat-bottom styles add base stability at larger volumes, standard stand-up formats balance shelf impact with material efficiency at smaller sizes.

custom spout pouches quote

Tell us about your product and line—our engineers will recommend fitments, materials, and timelines tailored to you.