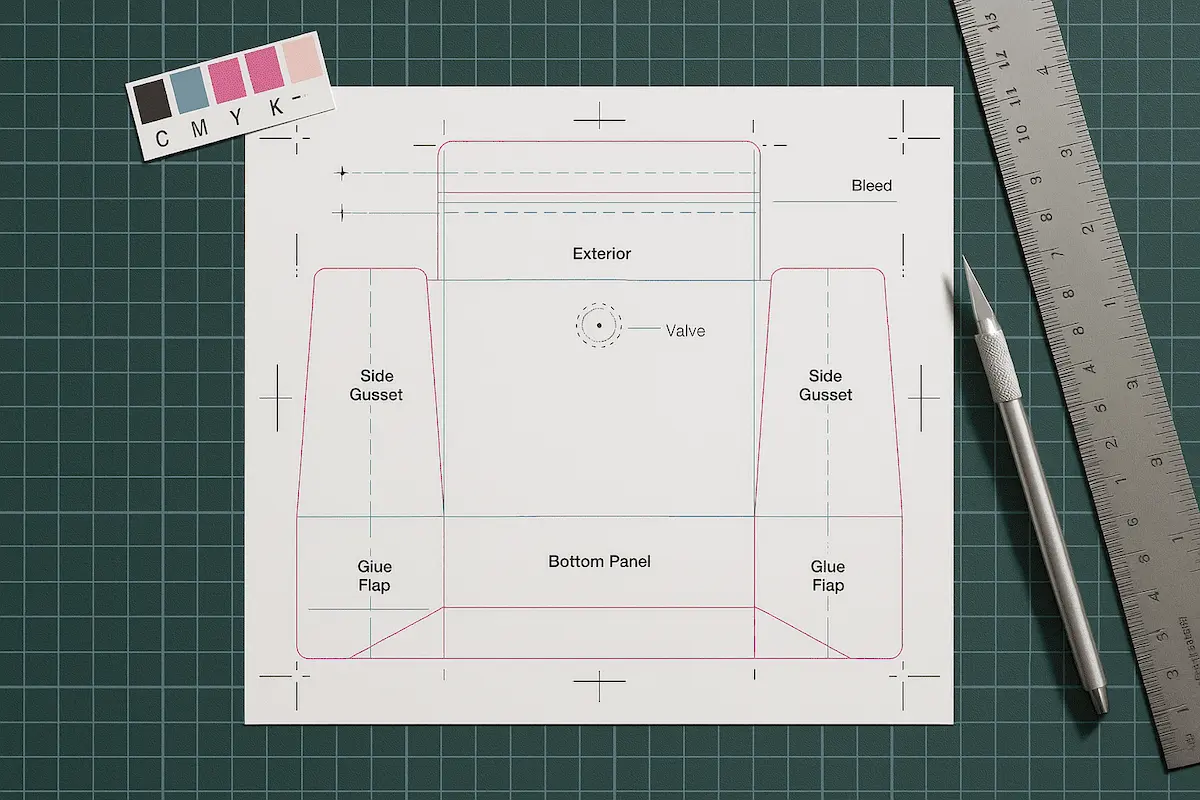

| Shelf impact & print |

Five printable panels = “billboard” branding; clean, box-like shape that reads premium.

|

Large front/back panels; bottom gusset adds shape when filled—great everyday visibility.

|

Front/back + side gussets give generous space; strong presence for larger formats.

|

| Stability & capacity |

Self-standing flat base; compact shelf footprint for coffee, snacks, 1 lb–1 kg.

|

Stands once filled; ideal for small-to-mid sizes and lightweight SKUs.

|

Four corner seals + tall gussets = high rigidity & volume; excels with heavier/bulkier SKUs.

|

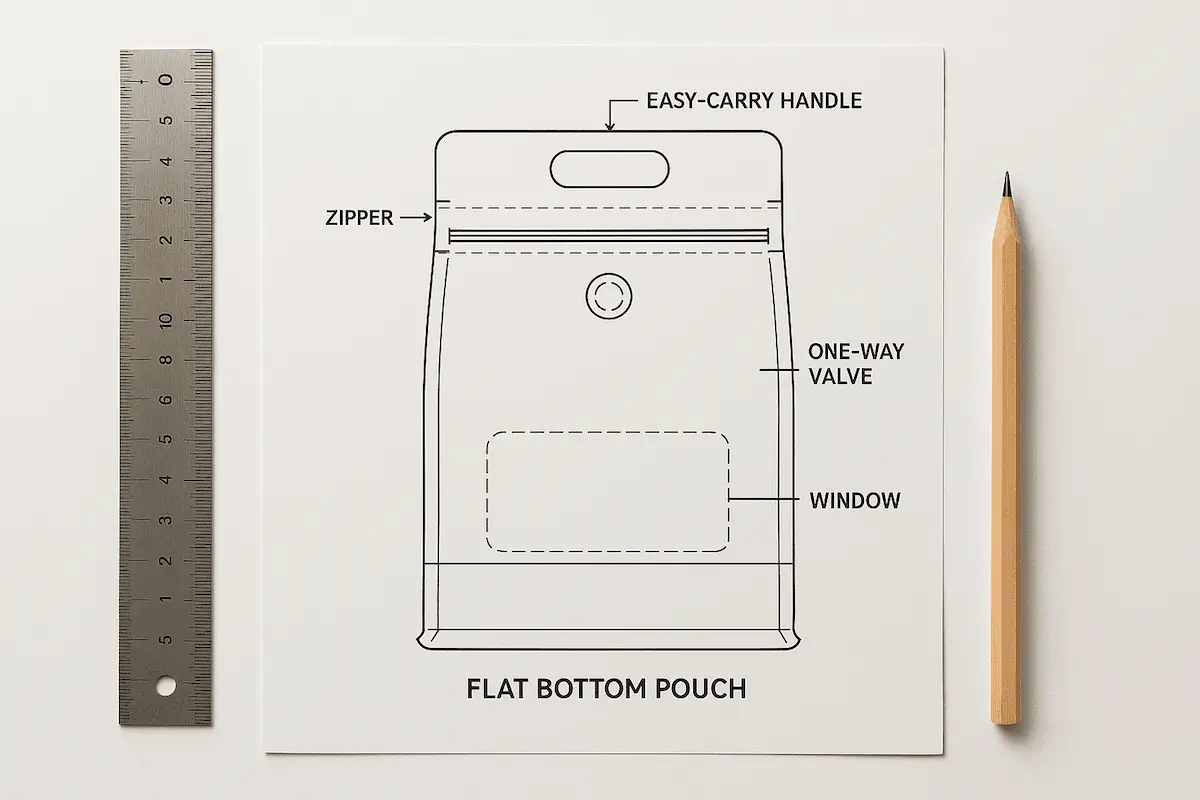

| Valve / closures |

Valve-ready for coffee; zippers, tear notches, hang holes supported.

|

Widely available with one-way degassing valves and zippers.

|

Common on coffee/pet food; valves, tin ties, scoop-friendly options.

|

| Sustainability paths |

Available in mono-PE (store drop-off recyclable) or compostable kraft builds.

|

Broad availability in mono-PE (store drop-off) and compostable kraft lines.

|

Now offered in mono-PE recyclable variants from major converters.

|

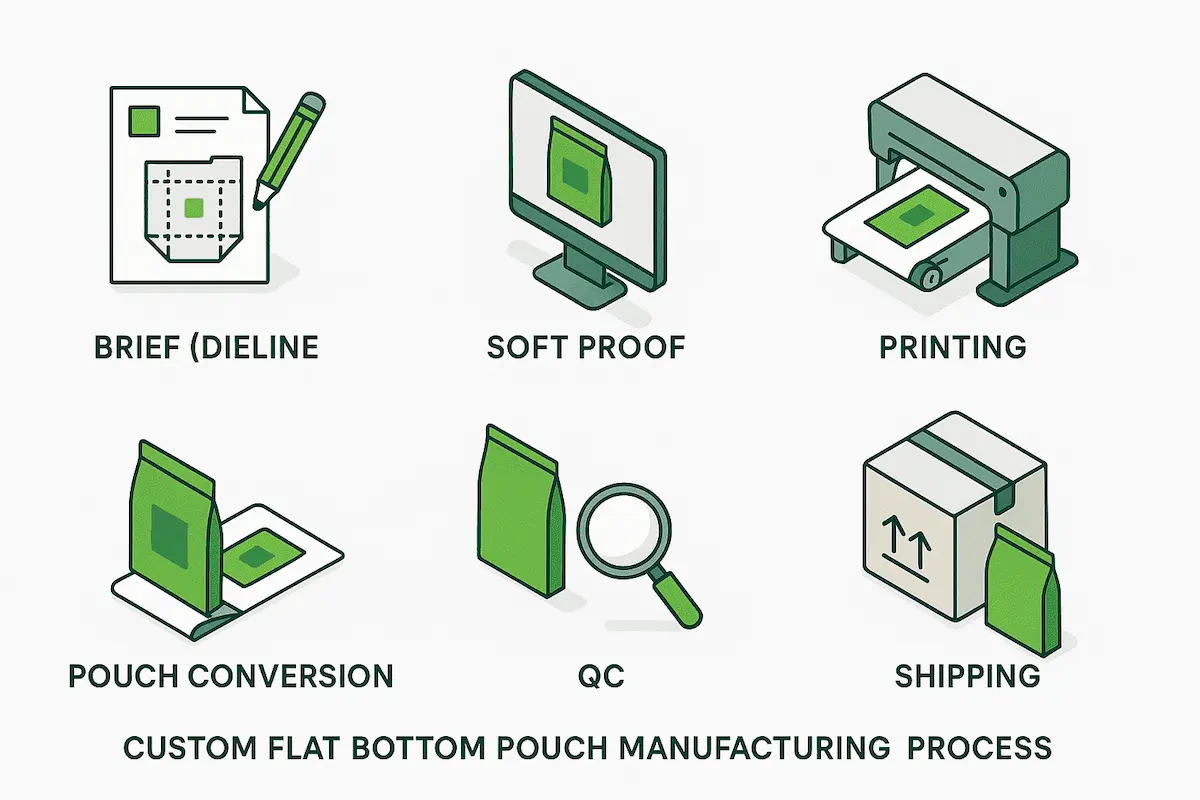

| Cost profile |

Highest unit cost (most complex make); chosen for premium branding.

|

Most cost-efficient/fastest lead times in many cases.

|

Typically between the two; efficient for larger fills.

|

| Choose this if… |

You want maximum branding + rock-solid shelf presence in retail.

|

You need value, speed and flexibility for small-to-mid sizes.

|

You need strength & volume for heavier loads (coffee 2–5 lb, pet food, bulk).

|