Selling candy without the right packaging is like serving soup in a paper cup—it leaks customer trust and freshness.

To maintain candy freshness and boost shelf appeal, custom packaging must balance material choice, structural integrity, and smart design.

As someone who has worked with global confectionery brands, I’ve seen how thoughtful packaging not only preserves candy quality but also significantly influences purchasing decisions and brand loyalty1. Let’s explore the essential elements that make candy packaging both functional and unforgettable.

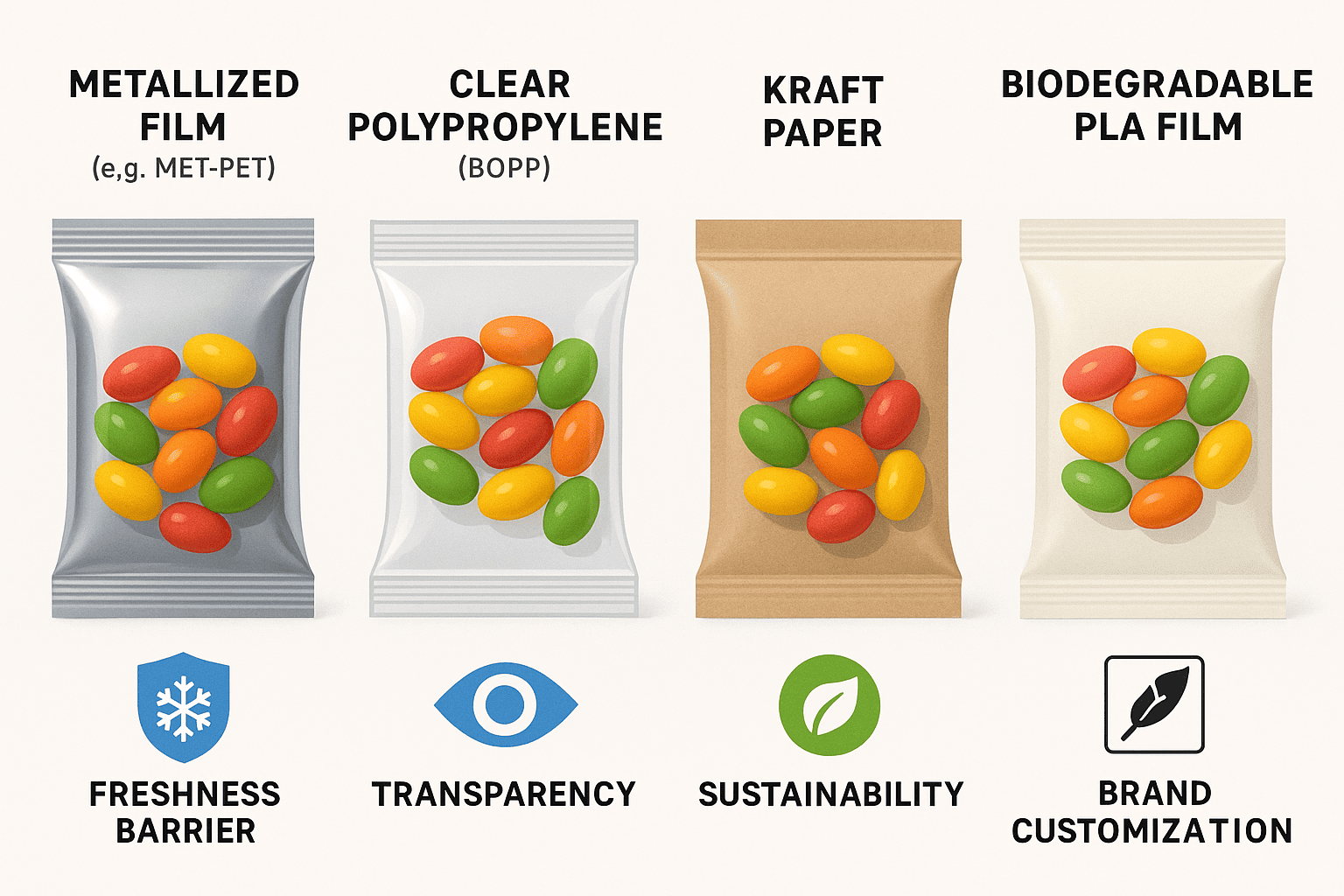

Choosing the Right Materials for Candy Packaging

Cheap materials lead to stale candy and a forgettable brand experience. That’s a recipe for customer churn.

The best candy packaging materials2 protect freshness, support branding, and match your product’s unique needs.

Common material types: plastic films, foils, paperboard, compostable alternatives

Depending on your candy type—gummies, chocolates, hard candies—you’ll need different material properties:

- Plastic films (PET, PE, BOPP): Lightweight, versatile, good for moisture barriers.

- Aluminum foil laminates: Excellent oxygen and light barrier, often used for chocolates.

- Paperboard: Great for rigid boxes3 and outer packaging, adds a premium feel.

- Compostable films (PLA, cellulose-based): A sustainable choice gaining popularity with eco-conscious brands.

Many brands use multi-layer laminates to combine strengths from different materials. For example, a PET/VMPET/PE structure offers durability, barrier performance, and heat-sealability.

Factors influencing material selection: product type, shelf life, brand image

When clients ask me what material to use, I always consider these three things:

- Candy type: Chocolates need protection from heat and light, while gummies need moisture control.

- Shelf life goals: Longer shelf life4 requires stronger barriers like metallized films or foil.

- Brand image: A luxury brand may opt for premium matte finishes, while a sustainable brand may choose compostable films5.

Choosing the wrong material can lead to spoilage, customer complaints, and brand damage. Material selection isn’t just technical—it’s strategic.

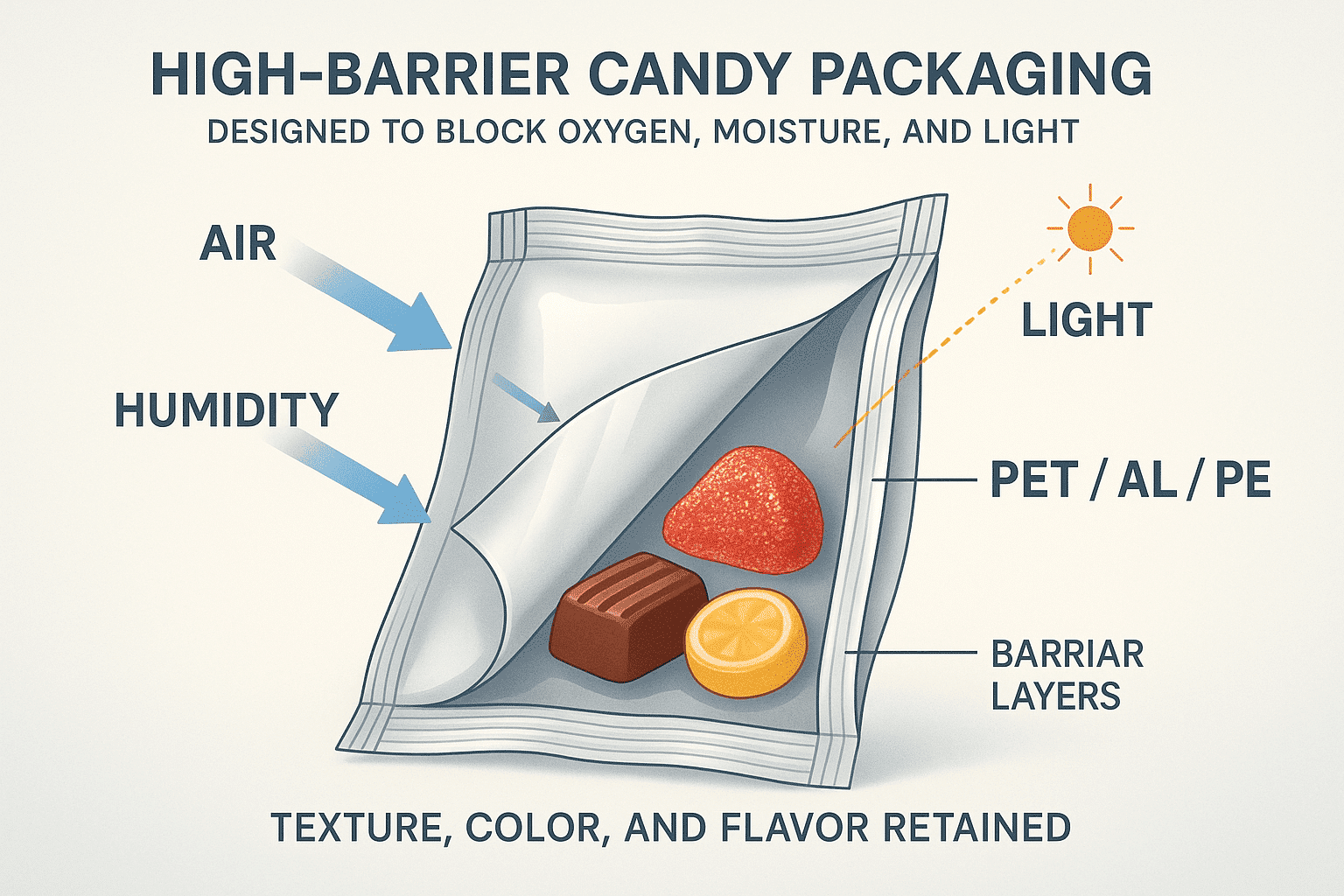

Barrier Properties and Freshness Retention

Even the best candy goes stale if exposed to air, moisture, or light. That’s not only a waste—it’s a brand risk.

Effective barrier properties6 are essential to maintain texture, flavor, and color throughout the product’s shelf life.

How oxygen, moisture, and light affect candy quality

- Oxygen causes oxidation, especially in chocolates and oil-based fillings, leading to rancidity.

- Moisture can harden gummies or soften hard candies, destroying texture.

- Light can fade colors and degrade ingredients like dairy or fruit extracts.

Each type of candy reacts differently, so barrier needs vary. That’s why I always run tests using different structures before finalizing a packaging spec.

Technologies and material coatings that extend shelf life

There are several ways to enhance barrier performance:

- Metallized films (VMPET, VMCPP): Block light and reduce moisture/oxygen transmission.

- Aluminum foil layers: Offer nearly zero permeability—ideal for premium chocolates.

- Coatings (PVDC, EVOH): Applied to plastic films7 to improve barrier without sacrificing clarity.

Pairing these barriers with nitrogen flushing or desiccants can further extend shelf life. I’ve helped brands double their freshness window just by optimizing their packaging layers.

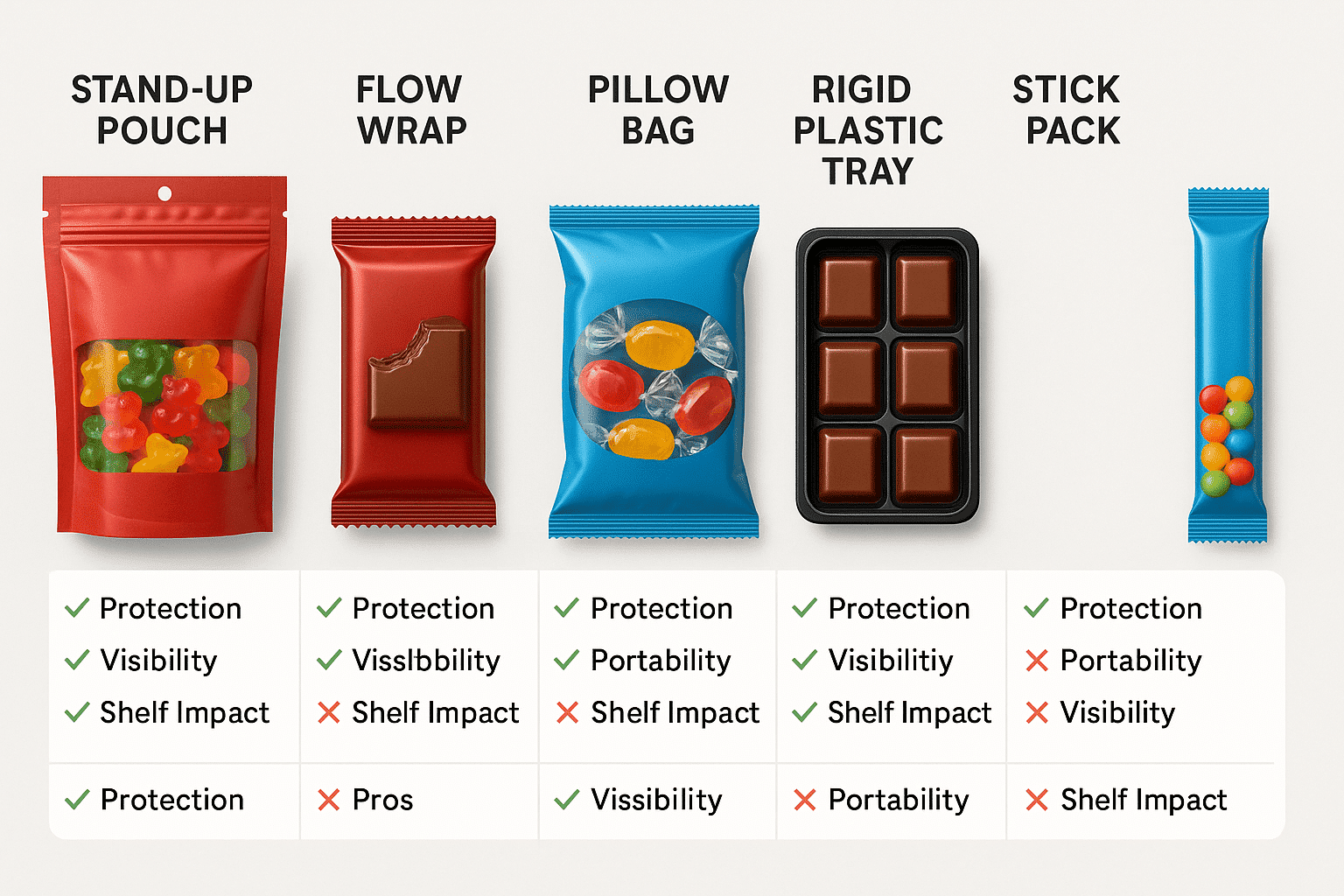

Packaging Formats and Structural Choices

The wrong format can result in crushed candy, waste, or poor shelf visibility—none of which help your brand.

Choosing the right packaging format ensures protection, functionality, and visual appeal.

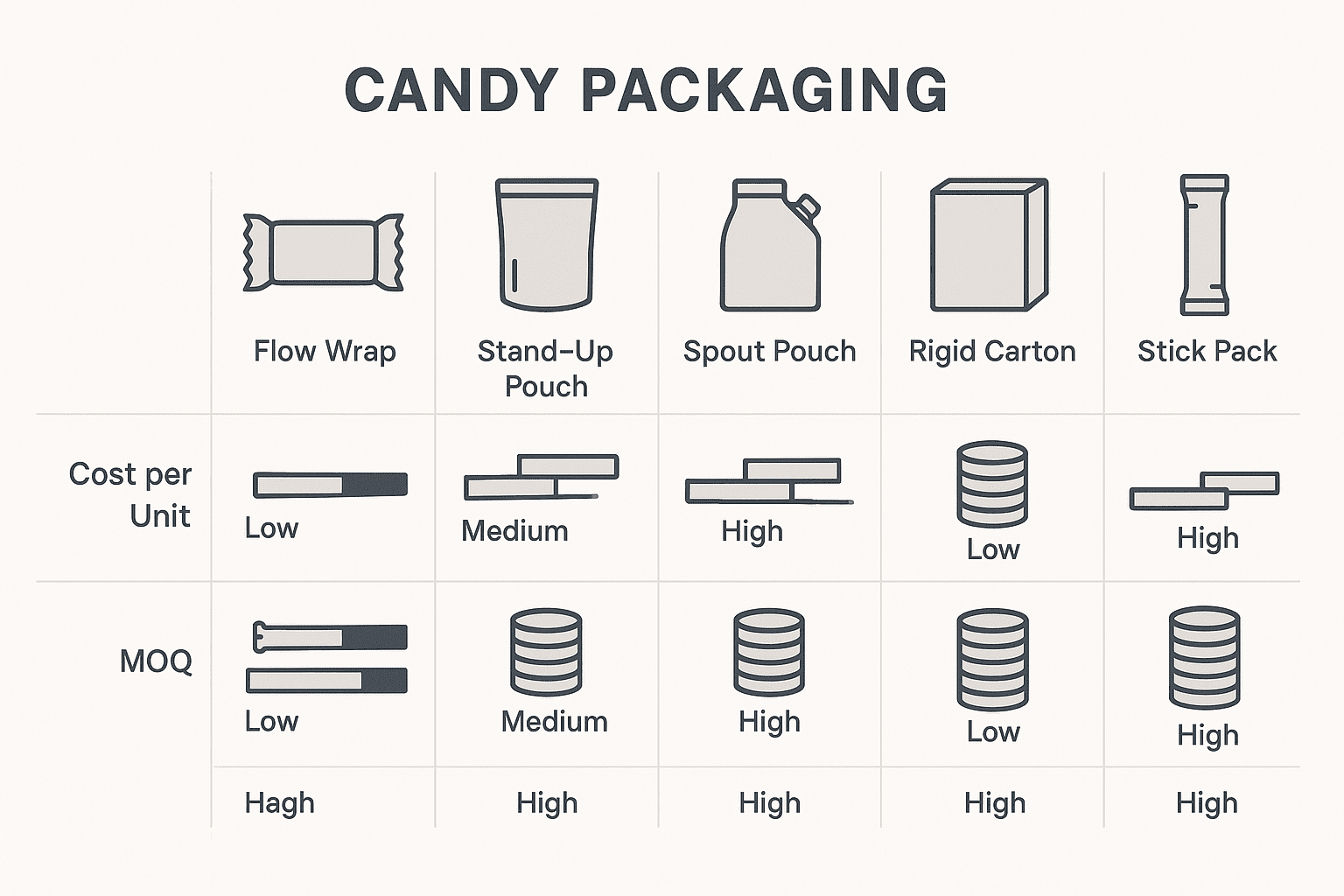

Popular formats: pouches, flow wraps, rigid boxes, blister packs

Here are some common formats I’ve worked with:

- Stand-up pouches (SUPs): Great for gummies or bulk candy; customizable and space-efficient.

- Flow wraps: Ideal for individually wrapped bars or sticks; fast to produce.

- Rigid boxes: Create a premium unboxing experience, perfect for gift sets or seasonal lines.

- Blister packs: Used for mints or gum; provide portion control and protection.

Your choice should align with your distribution channel—retail, DTC, vending—and storage conditions.

Structural considerations for protection during shipping and display

Shipping and retail environments can be brutal. I recommend:

- Reinforced gussets and seals for pouches to prevent bursting.

- Insert trays or partitions in boxes to keep candies from shifting.

- Hang holes or euro slots for peg displays.

- Anti-scuff finishes to preserve print quality during transit.

Good structural design reduces returns, enhances shelf presence, and improves customer satisfaction.

Branding and Design Elements

You could have the best candy in the world—but if the packaging doesn’t stand out, it won’t sell.

Packaging is your silent salesman. It tells your story in 3 seconds or less.

Using packaging to convey brand identity and attract buyers

I always ask clients: what do you want customers to feel when they see your product?

- Playful and fun? Use bold colors and quirky graphics.

- Premium and elegant? Try metallic inks, minimalist layouts, and matte finishes.

- Natural and healthy? Go with kraft textures and earthy tones.

The packaging should reflect your values and differentiate you on the shelf. A good designer does more than make it pretty—they align it with your positioning.

Color, typography, and graphics that resonate with target audiences

Colors and fonts carry emotional weight:

- Bright colors appeal to kids and impulse buyers.

- Pastels and neutrals work well for upscale or health-focused brands.

- Custom illustrations can add charm and storytelling value.

- Readable fonts are critical—if your label info is hard to read, it hurts trust.

I often guide clients to test multiple mockups with their audience before committing to a final design. Data beats guesswork.

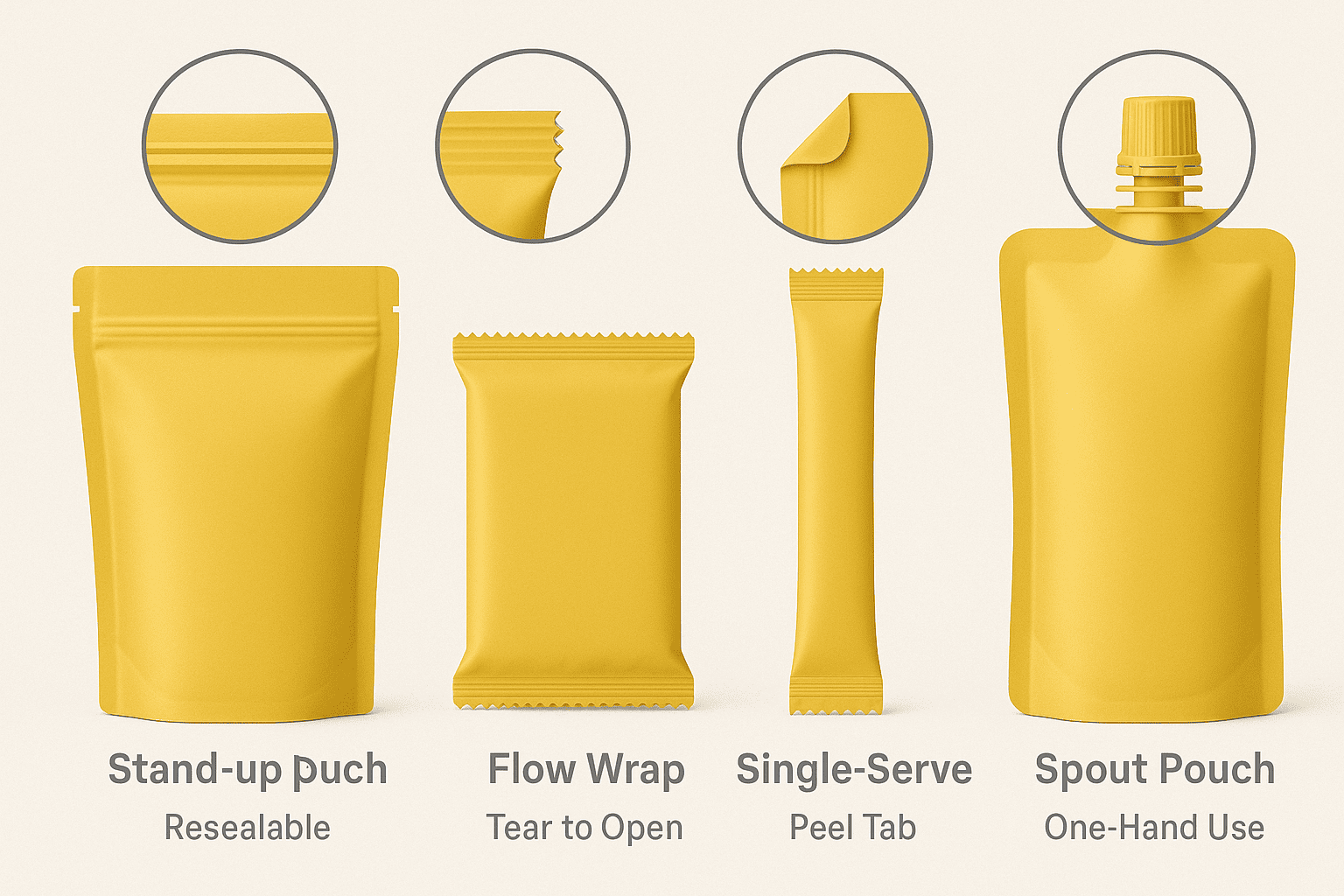

Ease-of-Use Features That Enhance Customer Experience

Frustrating packaging leads to bad reviews—even if the candy tastes great.

User-friendly features increase customer satisfaction, repeat purchases, and reduce waste.

Resealable closures, portion control, and intuitive opening mechanisms

Here are features I often recommend:

- Zippers or press-to-close seals for pouches—keep candy fresh after opening.

- Tear notches or easy-peel films—no scissors needed.

- Single-serve packs for portion control—great for health-conscious markets.

These aren’t just convenience—they become part of your product experience. Good packaging gets remembered.

Accessibility and convenience as competitive advantages

Not everyone has strong hands or perfect vision. Inclusive design matters.

- Large font sizes for ingredients and allergens.

- Easy-open tabs for seniors or kids.

- Clear windows to show the product inside.

When you focus on usability, you widen your customer base and build trust. I’ve seen brands win over niche markets just by making packaging easier to use.

Cost-Efficiency, Budgeting, and Minimum Order Quantities (MOQs)

Overspending on packaging can choke your cash flow. Underspending can hurt brand perception.

Successful brands find the sweet spot between cost, quality, and flexibility.

Balancing design ambition with cost constraints

You don’t need gold foil and embossing on every SKU. Instead, I help clients prioritize:

- Core SKUs get premium designs.

- Seasonal items use simplified versions.

- Digital printing for small runs without plate costs.

I also advise on using shared tooling or modular die-lines to cut setup costs across multiple products.

Planning production runs and managing inventory efficiently

MOQs can be intimidating, especially for startups. Here’s how I help clients manage:

- Forecast demand as accurately as possible.

- Choose scalable formats that work across flavors.

- Negotiate batch production to reduce per-unit cost.

I’ve even helped brands co-pack with other companies to meet MOQs without waste. Smart planning saves money and reduces stress.

Sustainable Packaging Solutions

Customers are demanding greener packaging. Falling behind on sustainability can hurt your image—and sales.

Eco-friendly packaging is now a competitive advantage, not just a nice-to-have.

Eco-friendly material options and certifications

Some options I recommend:

- Compostable PLA films for flow wraps and pouches.

- Recyclable mono-materials like PE or PP.

- Paper-based laminates with high barrier coatings.

Look for certifications like OK Compost, FSC, or TUV Austria to boost credibility. I also help clients communicate these features clearly on pack.

Reducing environmental impact without compromising product protection

Going green doesn’t mean sacrificing quality. Use strategies like:

- Lightweighting to reduce material use.

- Right-sizing to cut shipping volume.

- Refill packs for repeat customers.

I’ve seen brands reduce packaging waste by 30% and still improve product shelf life. Sustainability and performance can go hand-in-hand with the right guidance.

Effective custom candy packaging8 is more than just a wrapper—it’s a strategic tool that preserves freshness, elevates the customer experience9, and strengthens your brand. By considering the right materials, structure, and design, you can create packaging that delights customers and supports long-term business growth.

-

Explore the connection between packaging design and customer loyalty. ↩

-

Discover the various materials that can protect your candy and enhance its appeal. ↩

-

Find out how rigid boxes can create a premium unboxing experience for customers. ↩

-

Discover strategies to enhance your candy’s shelf life through effective packaging. ↩

-

Explore sustainable packaging options that appeal to eco-conscious consumers. ↩

-

Learn about the importance of barrier properties in maintaining candy quality. ↩

-

Learn how plastic films can provide moisture barriers and improve shelf life for your candy. ↩

-

Explore this resource to learn how to enhance your candy’s freshness and brand impact through effective packaging. ↩

-

Learn how thoughtful packaging can enhance customer satisfaction and loyalty. ↩