Custom Dry Food Packaging That Protects Your Product and the Planet

Whether you pack rice, flour, pasta, herbs, or aromatic spices, PackagingBest engineers barrier pouches and roll-stock that lock out moisture and oxygen while showcasing your brand. From digitally-printed test runs to full-scale rotogravure, we scale with you—without compromising sustainability.

- Low MOQ 1000 pcs

- 15–22 Day Lead Time

- Recyclable & Compostable Options

Why Dry Food Brands Switch to PackagingBest

From extending shelf-life to hitting ambitious sustainability targets, our dry food packaging solutions eliminate the three headaches that drain time and profit for rice, flour, pasta, and spice producers.

Proven Barrier Performance

Every dry food packaging structure is engineered to the exact OTR/WVTR your product needs, locking out moisture and sealing in aroma.

Low MOQ, Rapid Scaling

Validate new SKUs with 1,000-piece digital runs, then scale seamlessly to 5,000+ rotogravure bags or roll-stock—no supplier switch required.

Certified Sustainable Materials

Select Mono-material PE/PP recyclable or PLA-based compostable dry food packaging films, all backed by TUV OK Compost and GRS credentials.

Dry Food Packaging Tailored for Rice, Flour & Spices

Rice & Pulses Packaging

-

🎯What matters:

puncture resistance, stand-up display, crystal-clear grain visibility

- ✅Our fix:

- 💡PET/NY/PE traditional laminates for strength and gloss

- 💡Recyclable MDOPE/PE or economical BOPP/CPP when sustainability or cost is key

- 💡Gusset reinforcements and laser-score tear notches for easy pour-out

Fine Flours & Starches Bags

-

🎯What matters:

powder dusting, seal contamination, consumer convenience

- ✅Our fix:

- 💡PET/NY/PE or recyclable PE/EVOH-PE / MDOPE/PE with matte exterior to hide fingerprints

- 💡Powder-lock zippers plus narrow laser scoring for clean first-time opens

- 💡Anti-static liners to reduce clumping during filling

Aromatic Spices & Herbs Bags

-

🎯What matters:

volatile-oil loss, light oxidation, flavor migration

- ✅Our fix:

- 💡High-barrier MATOPP/VMPET/PE or MATOPP/AL/PE laminates to block oxygen and UV

- 💡Optional kraft-paper exterior or black-out layer for premium look and extra light protection

- 💡Compostable choices like PLA/VMPla/PLA or NK/Kraft/PLA for organic product lines

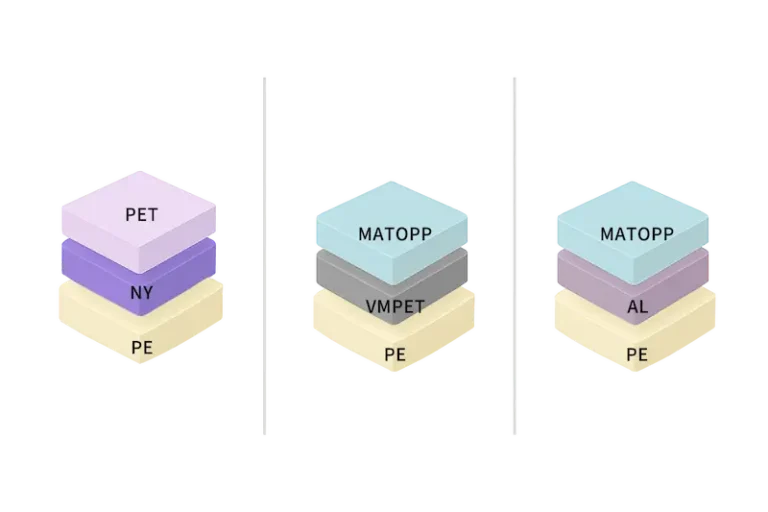

Material Structures & Barrier Levels

Pick the film that meets your shelf-life target and sustainability pledge. Every option below is food-grade, printable, and custom-gauged for dry food packaging.

For cost-effective strength and 12-18 month protection

- PET/NY/PE: go-to laminate for rice, flour

- MATOPP/VMPET/PE: extra light & aroma shield for spices and herbs

- MATOPP/AL/PE: highest oxygen barrier when exporting to hot, humid zones

✅Typical uses: bulk rice sacks, 1 kg flour pouches, retail spice refills

Store-drop recyclable solutions that still block moisture

- MDOPE/PE: mono-material, glossy shelf look

- PE/EVOH-PE: higher barrier via thin EVOH core

- BOPP/CPP: clear PP for cereals, pulses

✅Typical uses: sustainable rice or pet-food lines, refills that must meet retailer recyclability mandates

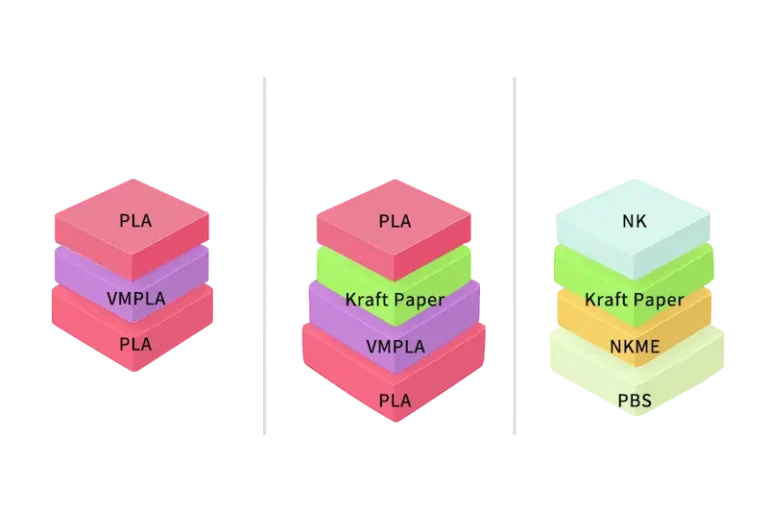

Certified industrial-compostable for premium organic SKUs

- PLA/VMPLA/PLA | PLA/Kraft/VMPLA/PLA

- NK/Kraft/NKME/PBS (cellulose-paper with bio-based seal layer)

✅Typical uses: small-format gourmet spices & herbs, farmers-market gift packs

(Not recommended for high-volume rice/flour due to current cost & water-vapor limits)

4 Fast Steps to Your Custom Dry Food Packaging

Share Your Requirements

Fill out the quote form or WhatsApp us with: product type (rice, flour, spices…), target shelf-life, preferred bag style, and print artwork. — Takes 5 minutes.

Approve Your 24-Hour Proof & Quote

Our engineers email a detailed material suggestion, digital proof, and itemized price within one business day. Tweak anything; we revise until you’re happy.

Production & Quality Check (15–22 Days)

We print digitally for 1 000-piece test runs or switch to rotogravure for 5 000+ orders. Every batch of dry food packaging passes seal-strength, drop, and vacuum tests before dispatch.

Global Shipping & After-Sales Support

Choose FOB China port or door-to-door delivery. Track your shipment online and reorder with one click when inventory runs low.

Frequently Asked Questions About Dry Food Packaging

Quick answers to the issues most dry-food brands raise when they’re choosing a new pouch or roll-stock supplier.

What is dry food packaging and why is barrier performance critical?

“Dry” foods like rice, flour or spices are hygroscopic—they pull moisture and oxygen out of the air. A multilayer barrier film keeps water vapour transmission (WVTR) and oxygen transmission (OTR) low, so texture and flavour stay intact during storage and shipping.

Which materials are most common for dry food packaging bags?

- PET / NY / PE for strength and gloss

- MAT OPP / VMPET / PE for extra light/oxygen protection

- MDOPE / PE or BOPP / CPP when recyclability or cost is the priority

- PLA-based laminates for brands that want an industrial-compostable option

Can dry food packaging be recyclable or compostable?

Yes. Mono-PE films meet store-drop recycling schemes, while PLA/Kraft structures can carry TÜV OK Compost certification for industrial composting.

How long will rice, flour or spices stay fresh in the right package?

Kept below 60 °F / 16 °C in a high-barrier pouch, most grains remain premium quality for 9-12 months, and delicate dried fruits or vegetables around six months.

What bag styles work best for dry foods?

- Stand-Up Pouch: retail spices, 8 oz–5 lb rice

- Flat Bottom Bag: 2–20 kg bulk rice or flour—square base resists pallet crush

- Roll-Stock Film: high-speed production lines for pasta and cereals

What is the minimum order quantity and lead time for custom dry food packaging?

Digital print runs start at 1 000 pcs per design, rotogravure at 5 000 pcs. Standard lead time is 15–22 days from artwork approval, with rush service available.

Do I need FDA-compliant materials for dry food packaging?

Absolutely. FDA 21 CFR parts 170-178 regulate any substance that contacts food. All our films use resins and inks cleared for direct food contact, and production follows the BRCGS food-safety standard.

How do I choose between standard, recyclable and compostable films?

First match your shelf-life target, then align with brand sustainability goals or retailer mandates. Our engineers compare OTR/WVTR data and run shelf tests to recommend the optimum film—often a recyclable MDOPE/PE for mainstream SKUs and a PLA/Kraft laminate for organic lines.

What are the packaging requirements for dry goods?

US food-safety rules require packaging that:

- Protects against moisture, oxygen, pests and physical damage (enhanced-barrier plastic films or foil laminates).

- Uses food-grade materials cleared by FDA for direct contact with food (see FDA’s “Food Ingredients & Packaging” resource).

- Is clean, intact and properly labelled, and stored at least 6 inches (15 cm) off the floor and 18 inches from outer walls to prevent condensation and allow pest control.

Need Reliable Dry Food Packaging? Get a Free Quote in 24 Hours

Fill out a quick form on the right and receive within one business day:

- Custom barrier film & bag style recommendation

- Free dieline and artwork review

- Itemised pricing (MOQ 1 000 pcs) and 15–22 day lead time

No obligation, No hidden fees.