Most people ask the wrong question about digital printing sustainability. They obsess over ink chemistry and machine specs. I’ve watched this pattern repeat for years across packaging projects.

Digital printing is sustainable, but not for the reasons most people think. The real environmental advantage comes from eliminating overproduction and obsolete inventory through on-demand, just-in-time manufacturing—not from the printing technology itself. While water-based inks and energy-efficient presses help, the biggest impact is preventing the 40% waste rate typical in traditional long-run printing.

Here’s what matters more than your ink type: I work with brands who proudly show me their "eco-friendly" offset prints. Then they admit 30-40% ends up in landfills because market trends shifted. The printing process was green. The business model was wasteful.

What Makes Digital Printing Different From Traditional Methods?

People focus on the wrong metrics when comparing printing methods. They count water usage and chemical consumption. These matter, but they miss the bigger picture.

Digital printing eliminates printing plates, reduces setup waste, and enables variable data printing for personalized output. Unlike offset printing that requires 5,000-10,000 unit minimums to be cost-effective, digital printing becomes economical at runs as small as 500-1,000 units. This fundamental difference enables demand-based production instead of forecast-based overproduction.

The Production Model Determines Real Impact

Traditional offset printing requires large runs to justify setup costs. I see brands order 50,000 units because the per-unit price drops. Six months later, they’re sitting on 20,000 obsolete packages.

Digital printing flips this model. You print 5,000 units. You test the market. You validate actual demand. Then you scale production to match consumption patterns.

Energy and Material Consumption Facts

The data shows clear differences. Digital presses consume less energy per impression for short runs. Research from Kujanpää et al. (2014) measured actual carbon footprints across different methods.

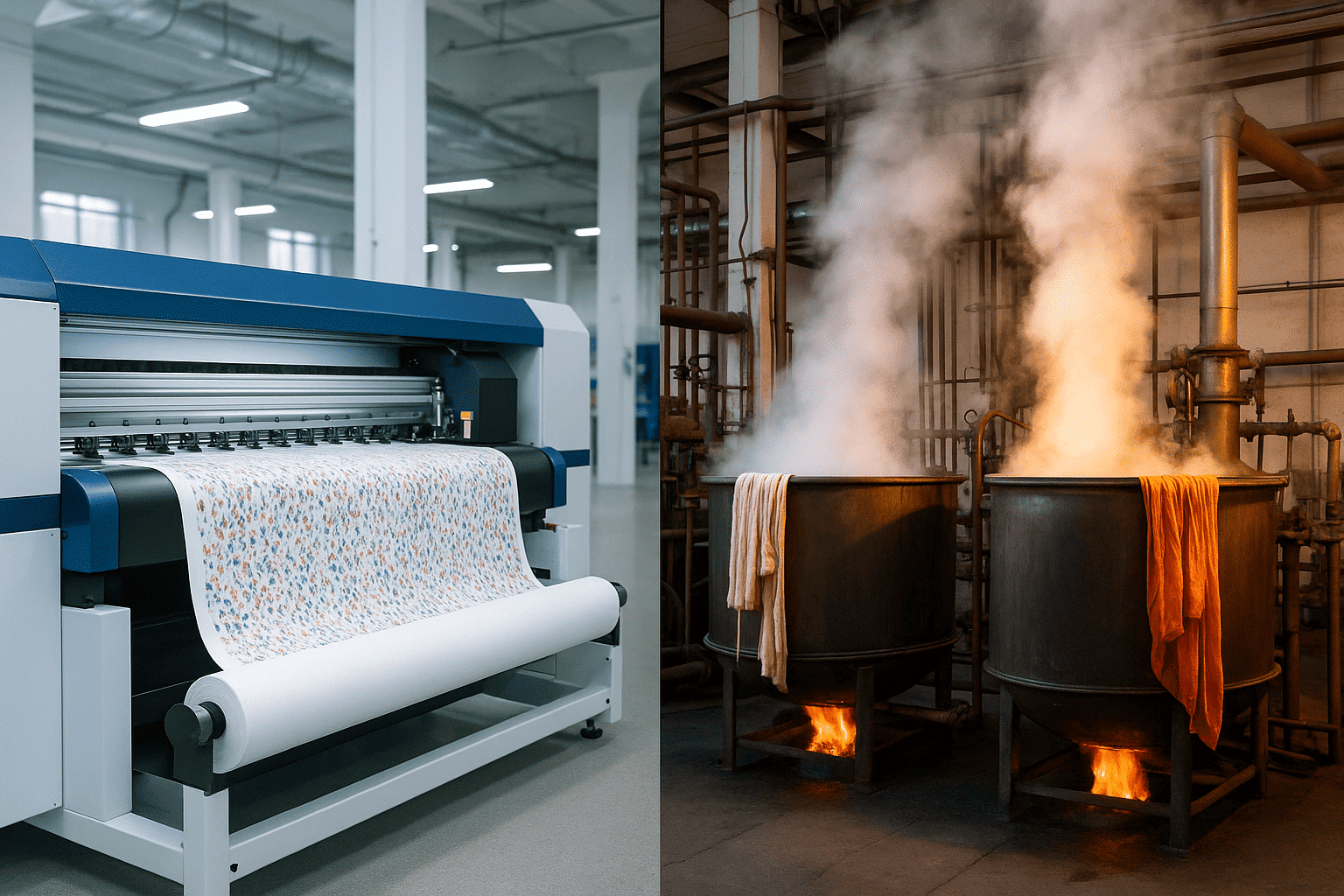

For 1 kg of fabric with 200 GSM in Europe:

- Digital printing: 2.6 kg CO2e

- Screen printing: 4.32 kg CO2e

- Fabric dyeing: 3.7 kg CO2e

Digital printing cuts emissions by 40% compared to screen printing. The savings come from eliminating test runs and reducing after-wash energy needs.

Material Waste Reduction

No printing plates means less physical waste. Every design change in offset printing requires new plates. Those plates wear out. They get discarded. The cycle repeats.

I’ve seen this waste pile up in printing facilities. Digital printing uploads files directly to the press. No plates. No setup materials. No disposal costs.

Does Digital Printing Really Reduce Inventory Waste?

This question reveals the core sustainability advantage. Most sustainability discussions focus on production. They should focus on distribution and consumption.

Digital printing enables print-on-demand workflows that reduce inventory waste by 60-80% compared to traditional bulk printing. Brands can produce exact quantities needed, respond to real-time market feedback, and avoid the structural waste embedded in forecast-driven manufacturing models that haven’t changed since the 1970s.

The Obsolescence Problem Nobody Talks About

I ask every client the same question: "What’s your actual depletion rate?" Most don’t know. They know their order quantity. They know their unit cost. They don’t track how fast they actually sell through inventory.

I worked with a supplement brand that discovered forty percent of their printed packaging never reached consumers because formulations changed before inventory depleted.

This gap creates massive waste. A brand orders packaging for 100,000 units. They forecast 18 months of sales. The market shifts in 6 months. New regulations appear. Recipe changes happen. Certification updates arrive.

Suddenly, 40,000 units of perfectly printed packaging become worthless. The ink was eco-friendly. The paper was recycled. The result was landfill.

Just-In-Time Production Reality

Digital printing makes just-in-time possible for packaging. You can run 2,000 units weekly instead of 50,000 units quarterly. This flexibility matters more than any ink formulation.

Consider the math:

- Traditional approach: 50,000 units, 40% obsolescence = 20,000 units wasted

- Digital approach: 2,000 units weekly × 25 weeks = 50,000 units, 5% obsolescence = 2,500 units wasted

The digital approach wastes 17,500 fewer units. That’s the real sustainability advantage.

Market Testing and Validation

Small runs enable market testing. You can launch with 5,000 units. You validate demand. You gather customer feedback. You adjust designs based on real data.

Traditional printing locks you into designs before you know what works. You print 50,000 units based on assumptions. You hope the market agrees with your forecast.

What About the Environmental Impact of Digital Printing Technology Itself?

The technology does matter. But it matters less than most people think. Let’s look at the actual data.

Modern digital printing systems produce 25% less CO2 emissions than previous models through improved fixing technology and reduced energy consumption. However, the environmental impact varies significantly based on electricity grid carbon intensity—digital printing in China saves 7.8 kg CO2/kg compared to screen printing, while in Europe the savings are 1.7 kg CO2/kg.

Ink Chemistry and Formulations

Water-based inks replaced solvent-based formulas in many digital systems. This change reduces hazardous air pollutants. HP Indigo systems use polymer-based inks with zero HAPs.

Pigment-based inks dominate over dye-based formulas now. They offer better deinkability for recycling. Several digital systems achieve 90-100 points on the INGEDE Method 11 scorecard for deinkability.

But here’s the truth: ink chemistry matters less than production volume optimization. A brand using solvent inks for 5,000 well-targeted units creates less total waste than a brand using water-based inks for 100,000 units with 40% obsolescence.

Energy Consumption Trends

Digital press energy consumption dropped 60% over the past decade for fixing processes. Newer toner formulations like Simitri V reduce fusing temperature by 15°C. This cuts overall energy use by 20-25%.

These improvements help. But they pale compared to avoiding 20,000 units of wasted production entirely.

Geographic Location Impact

The carbon intensity of your electricity grid matters significantly. Digital printing in regions with coal-heavy grids carries higher carbon costs.

In China, digital printing saves 7.8 kg CO2 per kg of fabric compared to screen printing. In Europe, the savings drop to 1.7 kg CO2 per kg. The technology is the same. The grid mix changes the outcome.

For packaging production, this means considering manufacturing location as part of your sustainability strategy. One client reduced their carbon footprint by relocating production from a coal-dependent region to a renewable-powered facility, despite higher labor costs.

Is Digital Printing More Sustainable Than Fabric Dyeing?

This comparison reveals nuanced trade-offs. The answer depends on your energy sources and production scale.

Digital printing generates approximately 1-2.6 kg less CO2 per kg of fabric compared to traditional dyeing methods, depending on fabric weight. The advantage comes from eliminating heat-intensive dyeing processes. However, in regions where dyeing facilities use renewable heat sources like biofuel or solar thermal, dyeing can match or beat digital printing’s carbon footprint.

Heat Requirements Drive Emissions

Dyeing requires significant heat to activate dyes and set colors. This heat typically comes from natural gas or coal. The carbon intensity of heat generation drives dyeing’s environmental impact.

Digital printing needs electricity for press operation. No hot water. No steam. No heat-based fixing for many systems. This structural difference creates the carbon advantage.

When Dyeing Makes Environmental Sense

Dyeing facilities switching to low-carbon heat sources change the equation. Solar thermal heating, heat pumps, or biofuel systems reduce dyeing’s carbon footprint significantly.

I’ve seen facilities achieve carbon-neutral dyeing through renewable heat sources. At that point, dyeing large solid-color runs becomes more efficient than digital printing for the same volume.

Scale and Application Matter

For small runs with complex patterns, digital printing wins clearly. For large runs of solid colors in facilities with renewable heat, dyeing may be more sustainable.

The right choice depends on your specific situation. Run size, design complexity, facility capabilities, and energy sources all factor into the calculation.

What About Sustainable Materials in Digital Printing?

Materials matter as much as the printing process. The most efficient printing of non-recyclable materials still creates waste problems.

Digital printing compatibility with sustainable substrates has improved dramatically. Modern systems handle recycled PE-PE films, post-consumer recycled content films, and compostable materials without quality loss. However, material sustainability depends more on end-of-life infrastructure than material composition—a recyclable film in a region without recycling infrastructure is functionally non-recyclable.

Recyclable Film Structures

PE-PE (polyethylene) structures dominate recyclable flexible packaging. These mono-material films work well with digital printing systems. They process through standard recycling streams in regions with proper infrastructure.

I recommend PE-PE structures for clients in markets with established recycling programs. The material recyclability matches well with digital printing’s waste reduction advantages.

Post-Consumer Recycled Content

PCR films incorporate recycled plastic back into new packaging. This closes the loop on plastic waste. Digital printing systems handle PCR content up to 30-50% without quality issues.

Higher PCR percentages can affect print quality and material performance. The trade-off between recycled content and functionality requires case-by-case evaluation.

Compostable Materials Reality

Compostable films sound ideal. The reality is more complex. Industrial composting facilities that accept flexible packaging are limited. Home composting rarely works for packaging films.

A compostable package in a region without industrial composting infrastructure ends up in landfills anyway. The material composition matters less than the available end-of-life infrastructure.

For my clients, I suggest compostable materials only when distribution areas have verified industrial composting access. Otherwise, recyclable materials with good recycling infrastructure create better environmental outcomes.

Material Testing and Validation

Digital printing enables material testing at commercial scale. You can run 1,000 units on a new sustainable substrate. You test real-world performance. You gather consumer feedback. You validate the material works before committing to large volumes.

Traditional printing requires larger test runs. This makes sustainable material experimentation more expensive and risky. Digital printing’s flexibility reduces barriers to trying new materials.

How Do You Verify Real Sustainability in Digital Printing?

Greenwashing is rampant in printing sustainability claims. Everyone claims eco-friendly operations. Few provide verifiable proof.

Credible sustainability verification requires third-party certification (EU Ecolabel, Blue Angel, FSC), documented energy consumption data, deinkability test results (INGEDE Method 11), and lifecycle analysis covering production through end-of-life. Self-certification and vague environmental claims without supporting data indicate potential greenwashing rather than genuine sustainability commitment.

Certification Standards That Matter

The EU Ecolabel and Blue Angel certifications require verified environmental performance. These aren’t pay-to-play marketing schemes. They require documented evidence and third-party auditing.

FSC certification verifies responsible forest management for paper-based materials. Cradle to Cradle certification assesses full lifecycle impact including material health and recyclability.

I look for multiple certifications from different organizations. Single certifications can be gamed. Multiple independent certifications provide stronger validation.

Energy and Emissions Documentation

Real sustainability requires data transparency. What’s the actual energy consumption per impression? What’s the carbon footprint per kilogram of output?

Companies providing specific numbers with methodology documentation demonstrate credible commitment. Vague claims about "reducing environmental impact" without data suggest greenwashing.

Deinkability Testing Results

For recyclable materials, deinkability determines whether recycling actually works. INGEDE Method 11 provides standardized testing. Scores above 90 points indicate excellent recyclability.

Digital printing systems achieving INGEDE certification demonstrate real environmental performance. Materials that can’t be effectively deinked create recycling contamination regardless of other sustainability claims.

Full Lifecycle Perspective

Production sustainability is one piece. Distribution, use, and end-of-life matter equally. A brand using eco-friendly printing but shipping globally via air freight undermines the sustainability advantage.

I evaluate total lifecycle impact including:

- Raw material sourcing and processing

- Manufacturing energy and waste

- Transportation and distribution

- Product use phase requirements

- End-of-life disposal or recycling

True sustainability requires optimization across all phases, not just printing.

What Questions Should You Ask Your Digital Printing Partner?

The right questions reveal genuine sustainability commitment versus marketing claims. I’ve developed a framework from years of supplier evaluation.

Ask for specific depletion rate analysis rather than standard order minimums, request documented energy consumption per unit, verify third-party environmental certifications, and demand lifecycle waste calculations including obsolescence rates. Suppliers focused on unit cost rather than total lifecycle cost often deliver higher environmental impact despite lower upfront pricing.

Depletion Rate Analysis

Most suppliers ask: "What’s your order quantity?" The right question is: "What’s your monthly depletion rate?"

This shift changes the conversation. Depletion rate determines optimal order frequency and volume. It prevents overproduction and obsolescence.

Suppliers who ask about depletion rates understand sustainability beyond production efficiency. They’re optimizing total system waste, not just printing efficiency.

Energy and Emissions Data

Request specific data:

- Energy consumption per kilogram of output

- Carbon emissions per production run

- Electricity source and grid carbon intensity

- Waste generation rates and disposal methods

Suppliers providing detailed answers demonstrate measurement and management capability. Vague responses suggest they don’t actually track environmental metrics.

Certification Verification

Don’t accept certification claims at face value. Request:

- Actual certification documents with registration numbers

- Third-party auditor reports if available

- Scope of certification (specific facilities or corporate-wide)

- Renewal dates and ongoing compliance verification

Real certifications come with documentation. Marketing claims come with logos.

Obsolescence and Waste Management

Ask how they handle obsolete inventory and production waste. Do they have take-back programs? Do they assist with end-of-life material recovery?

Suppliers treating waste as someone else’s problem don’t genuinely care about sustainability. Partners helping manage full lifecycle waste demonstrate real commitment.

Common Questions About Digital Printing Sustainability

1. Is digital printing always more sustainable than offset printing?

No. For very large runs of simple designs, offset printing can be more efficient per unit. Digital printing’s sustainability advantage comes from enabling smaller runs that match actual demand and prevent obsolescence waste. For runs under 10,000 units or designs requiring personalization, digital printing typically has lower total environmental impact.

2. Can you use recycled materials with digital printing?

Yes. Modern digital printing systems handle recycled and post-consumer recycled content materials effectively. PE-PE recyclable structures and PCR films up to 30-50% content work well with most digital systems. Material compatibility should be tested with specific substrates and printing systems before large production runs.

3. Does digital printing use less water than traditional methods?

Digital printing uses virtually no water during the printing process itself, unlike offset printing which requires plate development and cleanup water. However, some digital printing processes use water in pre-treatment or post-processing steps. Total water consumption depends on the specific digital printing technology and application.

4. How do I verify a printer’s sustainability claims?

Look for third-party certifications (EU Ecolabel, Blue Angel, FSC), request documented energy and emissions data, verify deinkability test results for recyclable claims, and ask for lifecycle analysis documentation. Be skeptical of vague environmental claims without supporting data or independent verification.

5. What’s more important: eco-friendly inks or reducing overproduction?

Reducing overproduction has greater total environmental impact in most cases. A brand using standard inks for 5,000 well-targeted units creates less total waste than a brand using eco-friendly inks for 100,000 units with 40% obsolescence. Optimize production volume first, then improve ink and material sustainability.

Conclusion

Digital printing’s sustainability advantage lies in enabling just-in-time production that eliminates structural waste, not in machine specifications or ink chemistry. The companies winning on sustainability use digital printing to match production with actual consumption, preventing the 40% obsolescence waste typical in traditional long-run printing forecasting models.